ʻO HV, HB, a me HRC nā ana o ka paʻakikī i hoʻohana ʻia i ka hoʻāʻo ʻana i nā mea. E wāwahi kākou iā lākou:

1)HV Hardness (Vickers Hardness): ʻO ka paʻakikī HV kahi ana o ke kūʻē ʻana o kahi mea i ka hoʻopaʻa ʻana. Hoʻoholo ʻia ma ka hoʻopili ʻana i kahi haʻawe i ʻike ʻia i ka ʻili o ka mea me ka hoʻohana ʻana i kahi indenter daimana a ana i ka nui o ka indentation hopena. Hōʻike ʻia ka paʻakikī HV i nā ʻāpana o ka paʻakikī Vickers (HV) a hoʻohana mau ʻia no nā mea lahilahi, nā uhi, a me nā ʻāpana liʻiliʻi.

2) HB Paʻakikī (Brinell Hardness): ʻO ka paʻakikī HB kekahi ana o ke kūʻē ʻana o kahi mea i ka indentation. Hoʻopili ia i ka hoʻopili ʻana i kahi haʻawe i ʻike ʻia i ka mea me ka hoʻohana ʻana i ka indenter pōpō kila paʻakikī a me ke ana ʻana i ke anawaena o ka indentation hopena. Hōʻike ʻia ka paʻakikī HB i nā ʻāpana o Brinell hardness (HB) a hoʻohana pinepine ʻia no nā mea nui a nui aʻe, me nā metala a me nā mea hoʻohui.

3)HRC paakiki (Rockwell Hardness): ʻO ka paʻakikī o ka HRC kahi ana o ke kūʻē ʻana o kahi mea i ke komo ʻana a i ʻole ke komo ʻana. Hoʻohana ia i nā unahi like ʻole (A, B, C, etc.) e pili ana i ke ʻano hoʻāʻo kikoʻī a me ke ʻano o ka indenter i hoʻohana ʻia (cone daimana a i ʻole pōpō kila paʻakikī). Hoʻohana mau ʻia ka unahi HRC no ke ana ʻana i ka paʻakikī o nā mea metala. Hōʻike ʻia ka waiwai paʻakikī ma ke ʻano he helu ma ka pālākiō HRC, e like me HRC 50.

Hoʻohana maʻamau ʻo HV-HB-HRC papaʻaina hoʻohālikelike paʻakikī:

| Papakaukau hoʻohālikelike paʻakikī ferrous metala maʻamau (kahi hoʻololi ikaika) | ||||

| Hoʻokaʻawale paʻakikī | Ka ikaika tensile N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | — | 211 | 211 | 710 |

| 17.5 | — | 214 | 214 | 715 |

| 18 | — | 216 | 216 | 725 |

| 18.5 | — | 218 | 218 | 730 |

| 19 | — | 221 | 220 | 735 |

| 19.5 | — | 223 | 222 | 745 |

| 20 | — | 226 | 225 | 750 |

| 20.5 | — | 229 | 227 | 760 |

| 21 | — | 231 | 229 | 765 |

| 21.5 | — | 234 | 232 | 775 |

| 22 | — | 237 | 234 | 785 |

| 22.5 | — | 240 | 237 | 790 |

| 23 | — | 243 | 240 | 800 |

| 23.5 | — | 246 | 242 | 810 |

| 24 | — | 249 | 245 | 820 |

| 24.5 | — | 252 | 248 | 830 |

| 25 | — | 255 | 251 | 835 |

| 25.5 | — | 258 | 254 | 850 |

| 26 | — | 261 | 257 | 860 |

| 26.5 | — | 264 | 260 | 870 |

| 27 | — | 268 | 263 | 880 |

| 27.5 | — | 271 | 266 | 890 |

| 28 | — | 274 | 269 | 900 |

| 28.5 | — | 278 | 273 | 910 |

| 29 | — | 281 | 276 | 920 |

| 29.5 | — | 285 | 280 | 935 |

| 30 | — | 289 | 283 | 950 |

| 30.5 | — | 292 | 287 | 960 |

| 31 | — | 296 | 291 | 970 |

| 31.5 | — | 300 | 294 | 980 |

| 32 | — | 304 | 298 | 995 |

| 32.5 | — | 308 | 302 | 1010 |

| 33 | — | 312 | 306 | 1020 |

| 33.5 | — | 316 | 310 | 1035 |

| 34 | — | 320 | 314 | 1050 |

| 34.5 | — | 324 | 318 | 1065 |

| 35 | — | 329 | 323 | 1080 |

| 35.5 | — | 333 | 327 | 1095 |

| 36 | — | 338 | 332 | 1110 |

| 36.5 | — | 342 | 336 | 1125 |

| 37 | — | 347 | 341 | 1140 |

| 37.5 | — | 352 | 345 | 1160 |

| 38 | — | 357 | 350 | 1175 |

| 38.5 | — | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | — | 1815 |

| 52 | 76.9 | 543 | — | 1850 |

| 52.5 | 77.1 | 551 | — | 1885 |

| 53 | 77.4 | 561 | — | 1920 |

| 53.5 | 77.7 | 570 | — | 1955 |

| 54 | 77.9 | 579 | — | 1995 |

| 54.5 | 78.2 | 589 | — | 2035 |

| 55 | 78.5 | 599 | — | 2075 |

| 55.5 | 78.7 | 609 | — | 2115 |

| 56 | 79 | 620 | — | 2160 |

| 56.5 | 79.3 | 631 | — | 2205 |

| 57 | 79.5 | 642 | — | 2250 |

| 57.5 | 79.8 | 653 | — | 2295 |

| 58 | 80.1 | 664 | — | 2345 |

| 58.5 | 80.3 | 676 | — | 2395 |

| 59 | 80.6 | 688 | — | 2450 |

| 59.5 | 80.9 | 700 | — | 2500 |

| 60 | 81.2 | 713 | — | 2555 |

| 60.5 | 81.4 | 726 | — | — |

| 61 | 81.7 | 739 | — | — |

| 61.5 | 82 | 752 | — | — |

| 62 | 82.2 | 766 | — | — |

| 62.5 | 82.5 | 780 | — | — |

| 63 | 82.8 | 795 | — | — |

| 63.5 | 83.1 | 810 | — | — |

| 64 | 83.3 | 825 | — | — |

| 64.5 | 83.6 | 840 | — | — |

| 65 | 83.9 | 856 | — | — |

| 65.5 | 84.1 | 872 | — | — |

| 66 | 84.4 | 889 | — | — |

| 66.5 | 84.7 | 906 | — | — |

| 67 | 85 | 923 | — | — |

| 67.5 | 85.2 | 941 | — | — |

| 68 | 85.5 | 959 | — | — |

| 68.5 | 85.8 | 978 | — | — |

| 69 | 86.1 | 997 | — | — |

| 69.5 | 86.3 | 1017 | — | — |

| 70 | 86.6 | 1037 | — | — |

HRC/HB Hoʻololi Manaʻo Manaʻo

ʻOi aku ka paʻakikī ma mua o 20HRC, 1HRC≈10HB,

ʻOi aku ka paʻakikī ma mua o 20HRC, 1HRC≈11.5HB.

Manaʻo: No ka ʻoki ʻana i ka hana, hiki ke hoʻololi like ʻia me 1HRC≈10HB (ʻo ka paʻakikī o ka mea hana he ʻano loli)

ʻO ka paʻakikī o nā mea metala

ʻO ka paʻakikī e pili ana i ka hiki i kahi mea ke pale aku i ka hoʻololi kūloko, ʻoi aku ka deformation plastic, indentation a i ʻole scratching. He kuhikuhi ia e ana i ka palupalu a me ka paakiki o ka mea.

Wahi a nā ʻano hoʻokolohua like ʻole, ua māhele ʻia ka paʻakikī i ʻekolu ʻano.

①ʻOʻoleʻa ʻōpala. Hoʻohana nui ʻia e hoʻohālikelike i ka palupalu a me ka paʻakikī o nā mineral like ʻole. ʻO ke ʻano o ke koho ʻana i ke koʻokoʻo me kekahi ʻaoʻao paʻakikī a ʻo kekahi ʻaoʻao palupalu, e hāʻawi i ka mea e hoʻāʻo ʻia ma ke koʻokoʻo, a e hoʻoholo i ka paʻakikī o ka mea e hoʻāʻo ʻia e like me ke kūlana o ka ʻōpala. Ma ka ʻōlelo kūpono, hana nā mea paʻakikī i nā ʻōpala lōʻihi a ʻo nā mea palupalu e hana pōkole.

②ʻOʻoleʻa paʻa. Hoʻohana nui ʻia no nā mea metala, ʻo ke ʻano ka hoʻohana ʻana i kekahi ukana e kaomi i ka indenter i ʻōlelo ʻia i loko o ka mea e hoʻāʻo ʻia, a hoʻohālikelike i ka palupalu a me ka paʻakikī o ka mea e hoʻāʻo ʻia e ka nui o ka deformation plastic kūloko ma luna o ka ʻili. ka mea. Ma muli o ka ʻokoʻa o ka indenter, ka ukana a me ka lōʻihi o ka ukana, nui nā ʻano o ka paʻakikī indentation, ʻo ia hoʻi me Brinell hardness, Rockwell hardness, Vickers hardness and microhardness.

③Paʻakiki hou. Hoʻohana nui ʻia no nā mea metala, ʻo ke ʻano o ka hāʻule ʻana o kahi hāmare liʻiliʻi kūikawā mai kahi kiʻekiʻe e hopena i ka hāpana o ka mea e hoʻāʻo ʻia, a hoʻohana i ka nui o ka ikehu kānana i mālama ʻia (a laila hoʻokuʻu ʻia) i ka hāpana i ka wā o ka hopena (ma ka hoʻihoʻi ʻana o ka hāmare liʻiliʻi) ke ana kiʻekiʻe lele) e hoʻoholo ai i ka paʻakikī o ka mea.

ʻO ka paʻakikī Brinell maʻamau, ka paʻakikī Rockwell a me ka paʻakikī Vickers o nā mea metala no ka paʻakikī indentation. ʻO ka waiwai paʻakikī e hōʻike ana i ka hiki o ka ʻili o ke kino ke pale aku i ka hoʻololi ʻana o ka plastic i hana ʻia e kekahi mea i kaomi ʻia i loko; C) e ana i ka paʻakikī, a ʻo ka waiwai paʻakikī e hōʻike ana i ka nui o ka hana hoʻololi elastic o ka metala.

ʻO Brinell Hardness

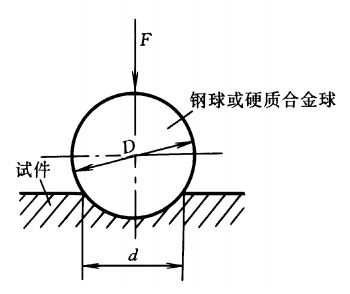

E hoʻohana i ka pōpō kila kinai ʻia a i ʻole ka pōpō huila paʻa me ke anawaena o D ma ke ʻano he indenter, e kaomi i ka ʻili o ka ʻāpana hoʻāʻo me ka ikaika hoʻāʻo like F, a ma hope o ka manawa paʻa i ʻōlelo ʻia, e hoʻoneʻe i ka ikaika hoʻāʻo e loaʻa kahi indentation me he anawaena o d. E puunaue i ka ikaika hoao ma ka ili o ka indentation, a o ka waiwai i loaa mai ka waiwai paakiki Brinell, a ua hoikeia ka hoailona e HBS a i ole HBW.

ʻO ka ʻokoʻa ma waena o HBS a me HBW ka ʻokoʻa i ka indenter. HBS 'o ia ho'i ka indenter he pōpō kila pa'akiki, i ho'ohana 'ia no ke ana 'ana i nā mea me ka waiwai pa'akikī Brinell ma lalo o 450, e like me ke kila ha'aha'a, ka hao hina a me nā metala non-ferrous. HBW 'o ia ho'i, 'o ka indenter he carbide cemented, ka mea i ho'ohana 'ia no ke ana 'ana i nā mea me ka waiwai pa'akikī Brinell ma lalo o 650.

No ka poloka ho'āʻo hoʻokahi, inā like nā kūlana hoʻokolohua ʻē aʻe, ʻokoʻa nā hopena o nā hoʻokolohua ʻelua, a ʻoi aku ka nui o ka waiwai HBW ma mua o ka waiwai HBS, a ʻaʻohe kānāwai quantitative e hahai.

Ma hope o ka makahiki 2003, ua hoʻokō like koʻu ʻāina i nā kūlana o ka honua, ua kāpae i nā mea hoʻokomo pōpō kila, a me nā poʻo pōpō carbide i hoʻohana ʻia. No laila, ua hoʻopau ʻia ka HBS, a ua hoʻohana ʻia ʻo HBW e hōʻike i ka hōʻailona paʻakikī Brinell. I nā manawa he nui, hōʻike wale ʻia ka paʻakikī Brinell ma HB, e pili ana iā HBW. Eia naʻe, ʻike ʻia ka HBS i kēlā me kēia manawa ma nā pepa palapala.

He kūpono ke ʻano ana paʻakikī ʻo Brinell no ka hao hao, nā mea hao non-ferrous, nā kila annealed a me nā mea i hoʻopaʻa ʻia, a ʻaʻole kūpono no ka hoʻāʻo ʻana i nā laʻana a i ʻole.ʻāpana hoʻohuli cncʻo ia ka paʻakikī, liʻiliʻi loa, ʻeleʻele loa, a i ʻole ʻae ʻole i nā kaha nui ma ka ʻili.

ʻO Rockwell Hardness

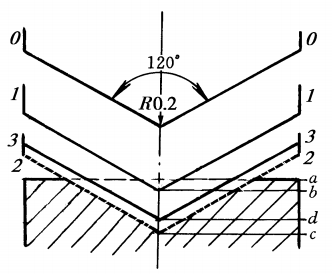

E hoʻohana i ka cone daimana me ka huina cone o 120° a i ʻole Ø1.588mm a me Ø3.176mm i pio kila pōlele e like me ka indenter a me ka ukana e hui pū me ia. ʻO ka ukana mua he 10kgf a ʻo ka ukana holoʻokoʻa he 60, 100 a i ʻole 150kgf (ʻo ia hoʻi, ka ukana mua me ka ukana nui). Hōʻike ʻia ka paʻakikī e ka ʻokoʻa ma waena o ka hohonu indentation i ka wā e wehe ʻia ai ka ukana nui a me ka hohonu indentation i ka wā e paʻa ai ka ukana nui a me ka hohonu indentation ma lalo o ka ukana mua ma hope o ka hoʻohana ʻana i ka ukana holoʻokoʻa.

Hoʻohana ka hoʻāʻo paʻakikī ʻo Rockwell i ʻekolu mau kaha hoʻāʻo a me ʻekolu indenters. He 9 hui o ia mau mea, e like me na unahi 9 o ka paakiki o Rockwell. ʻO ka hoʻohana ʻana o kēia mau lula 9 e uhi ana i nā mea metala maʻamau. ʻEkolu ʻekolu HRA, HRB a me HRC, ma waena o ka HRC ka mea i hoʻohana nui ʻia.

ʻO ka papa kuhikuhi hoʻāʻo paʻakikī ʻo Rockwell maʻamau:

| ʻoʻoleʻa | | | ʻoʻoleʻa | |

| | | | | ʻO ka carbide, carbide, |

| | | | | ʻO Annealed, kila maʻamau, aluminika |

| | | | | kila paʻakikī, kila kinai ʻia, hohonu |

ʻO ka laulā o ka hoʻohana ʻana i ka pālākiō HRC ʻo 20 ~ 70HRC. Ke emi ka waiwai paakiki ma mua o 20HRC, no ka mea, o ka conicalalumini cnc machining hapapaʻi nui ʻia ka indenter, emi ka naʻau, a pono e hoʻohana ʻia ka unahi HRB; ke ʻoi aku ka paʻakikī o ka hāpana ma mua o 67HRC, ʻoi aku ka nui o ke kaomi ʻana ma ka piko o ka indenter, a ua maʻalahi ka pōʻino o ke daimana. E hoʻopōkole loa ʻia ke ola o ka indenter, no laila e hoʻohana maʻamau ka pālākiō HRA.

He mea maʻalahi, wikiwiki, a liʻiliʻi ka hoʻāʻo ʻana o ka paʻakikī ʻo Rockwell, a hiki ke hoʻāʻo i ka ʻili o nā huahana i hoʻopau ʻia a me nā mea hana paʻa a lahilahi. Ma muli o ka liʻiliʻi indentation, no nā mea me ka uneven hale a me ka paakiki, ka paakiki waiwai fluctuates nui, a me ka pololei, aole e like me ka Brinell paakiki. Hoʻohana ʻia ka paʻakikī ʻo Rockwell e hoʻoholo ai i ka paʻakikī o ke kila, nā metala non-ferrous, nā ʻāpana paʻakikī, etc.

Vickers Hardness Vickers Hardness

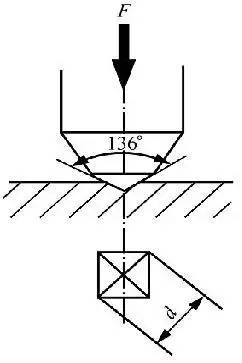

Ua like ke kumu o ke ana paakiki o Vickers me ko Brinell paakiki. E hoʻohana i ka indenter pyramid square diamond me kahi kihi i hoʻokomo ʻia o 136° e kaomi i ka ʻili o ka mea me ka ikaika hoʻāʻo F, a wehe i ka ikaika hoʻāʻo ma hope o ka mālama ʻana i ka manawa i ʻōlelo ʻia. Hōʻike ʻia ka paʻakikī e ka ʻawelike kaomi ma ka ʻāpana ili o ka indent pyramid square. ʻO ka waiwai, ʻo ka hōʻailona hōʻailona he HV.

He nui ke ana paakiki o Vickers, a hiki ke ana i na mea me ka paakiki mai 10 a 1000HV. He liʻiliʻi ka indentation, a hoʻohana maʻamau ia e ana i nā mea ʻoi aku ka lahilahi a me nā papa paʻakikī i luna e like me ka carburizing a me ka nitriding.

Leeb Paʻakikī Leeb Paʻakikī

E hoʻohana i kahi kino hopena me kahi poʻo pōpō tungsten carbide e hoʻopā i ka ʻili o ka ʻāpana hoʻāʻo ma lalo o ka hana a kekahi ikaika, a laila hoʻihoʻi hou. Ma muli o ka ʻokoʻa o ka paʻakikī o nā mea, ʻokoʻa ka wikiwiki o ka rebound ma hope o ka hopena. Hoʻokomo ʻia kahi magnet paʻa ma ka ʻaoʻao hopena. Ke neʻe ke kino hopena i luna a i lalo, e hoʻoulu ʻia kona ʻōwili peripheral i kahi hōʻailona electromagnetic e like me ka wikiwiki, a laila hoʻololi iā ia i waiwai paʻakikī Leeb ma o kahi kaapuni uila. Hōʻailona ʻia ka hōʻailona e like me HL.

ʻAʻole pono ka Leeb hardness tester i kahi papa hana, a ʻo kāna mea ʻike paʻakikī e like me ka peni, hiki ke hana pololei ʻia e ka lima, a hiki ke ʻike maʻalahi inā he mea hana nui, kaumaha a i ʻole kahi mea hana me nā ana geometric paʻakikī.

ʻO kekahi pōmaikaʻi ʻē aʻe o Leeb paʻakikī ʻo ia ka liʻiliʻi o ka pōʻino i ka ʻili o ka huahana, a i kekahi manawa hiki ke hoʻohana ʻia e like me ka hoʻāʻo ʻole luku; ʻokoʻa ia i nā hoʻāʻo paʻakikī ma nā ʻaoʻao āpau, nā ākea ākea a kūikawāʻāpana alumini.

Hoʻopili ʻo Anebon i ka ʻōlelo ʻo "Honest, hoʻoikaika, hoʻoikaika, hana hou" e loaʻa mau i nā hopena hou. Manaʻo ʻo Anebon i nā manaʻo, ʻo ka kūleʻa e like me kāna kūleʻa pilikino. E hana ʻo Anebon i ka lima maikaʻi i ka wā e hiki mai ana no nā ʻāpana mīkini keleawe a me nā ʻāpana cnc titanium paʻakikī. Loaʻa iā Anebon nā lako waiwai piha a ʻo ke kumukūʻai kūʻai aku ko mākou pono. Welina mai e nīnau e pili ana i nā huahana a Anebon.

ʻO nā huahana Trending China CNC Machinging Part a me Precision Part, inā paha e makemake ʻoe i kekahi o kēia mau mea, e ʻoluʻolu e ʻike iā mākou. E hauʻoli ʻo Anebon e hāʻawi iā ʻoe i kahi ʻōlelo ma ka loaʻa ʻana o nā kikoʻī kikoʻī. Loaʻa iā Anebon kā mākou loea pilikino R&D e hoʻokō i kekahi o nā koi. Manaʻo ʻo Anebon i ka loaʻa koke ʻana o kāu mau nīnau a ke manaʻolana nei e loaʻa ka manawa e hana pū me ʻoe i loko o ka wā e hiki mai ana. Welina mai e nānā i ka hui ʻo Anebon.

Ka manawa hoʻouna: Mei-18-2023