Nā koi o nā mīkini mīkini CNC ma nā mea hana

ʻO ka paʻakikī kiʻekiʻe a me ke kūpaʻa ʻaʻahu

Pono e ʻoi aku ka paʻakikī o ka ʻoki ʻana o ka mea hana ma mua o ka paʻakikī o ka mea hana. ʻO ke kiʻekiʻe o ka paʻakikī o ka mea paahana, ʻoi aku ka maikaʻi o kona pale ʻana. ʻO ka paʻakikī o ka mea paahana ma ka lumi wela ma luna o HRC62. Hiki ke kiʻekiʻe ka paʻakikī ma mua o ka mea maʻamauʻāpana mīkini CNC.

Ua lawa ka ikaika a me ka paʻakikī

Hāʻawi ka mea hana i ke kaomi maikaʻi ma ke kaʻina o ka ʻoki nui ʻana. I kekahi manawa, hana ia ma lalo o ka hopena a me nā kūlana vibration. I mea e pale aku ai i ka haki ʻana a me ka haki ʻana o ka mea hana, pono e lawa ka ikaika a me ka paʻakikī o ka mea paahana. ʻO ka maʻamau, hoʻohana ʻia ka ikaika kulou e hōʻike i ka ikaika o ka mea paahana, a hoʻohana ʻia ka waiwai hopena e wehewehe i ka paʻakikī o ka mea paahana.

ʻoi aʻe ka pale wela

ʻO ke kūpaʻa wela e pili ana i ka hana ʻana o nā mea paahana e mālama ai i ka paʻakikī, ke kūpaʻa ʻana, ka ikaika, a me ka paʻakikī ma lalo o nā wela kiʻekiʻe. He hōʻailona alakaʻi ia e ana i ka hana ʻoki ʻana o nā mea hana. ʻIke ʻia kēia hana ʻo ka ʻulaʻula paʻakikī o nā mea hana.

Maikaʻi ka wela wela

ʻOi aku ka nui o ka conductivity thermal o ka mea paahana, ʻoi aku ka nui o ka wela e hoʻoneʻe ʻia mai ka mea paahana, kahi e hoʻemi ai i ka ʻoki ʻana o ka mea hana a hoʻomaikaʻi i kona paʻa.

Maikaʻi ka hana ʻana

No ka hoʻomaʻamaʻa ʻana i ka mea hana a me ka hana ʻana, pono e loaʻa i nā mea paahana nā waiwai hana maikaʻi, e like me ka forging, rolling, welding, cutting and grindability, heat treatment properties, and high-temperature plastic deformation properties of tool tool. ʻO nā mea paahana cemented carbide a me nā mea hana seramika e pono ai ka sintering maikaʻi a me nā waiwai hoʻoikaika.

ʻAno mea paahana

kiʻekiʻe-wikiwiki kila

ʻO ke kila māmā holo kiʻekiʻe he mea kila kila i haku ʻia me W, Cr, Mo, a me nā mea hao ʻē aʻe. Loaʻa iā ia ke kūpaʻa wela kiʻekiʻe, ka ikaika, ka paʻakikī, a me ke ʻano o ka paʻakikī a me ke kūpaʻa ʻana, no laila kūpono ia no ka hoʻoili ʻana i nā mea metala non-ferrnonferrous a me nā mea metala like ʻole. Eia kekahi, ma muli o kāna ʻenehana hoʻoponopono kani, kūpono ia no ka hana ʻana i nā mea hana paʻakikī, ʻoi aku ka nui o ka pauka metallurgy kila kiʻekiʻe, nona nā waiwai anisotropic a hoʻemi i ka deformation quenching; kūpono ia no ka hana ʻana i ka pololei a me nā mea hana paʻakikī.

Paʻa paʻa

He kiʻekiʻe ka paʻakikī a me ka pale ʻana o ka carbide sima. Ke okiʻāpana huli ʻo CNC, ʻoi aku ka maikaʻi o kāna hana ma mua o ke kila kiʻekiʻe. ʻOi aku ka lōʻihi o ka lōʻihi o ke kila kiʻekiʻe, akā maikaʻi ʻole kona paʻakikī. Ma muli o kāna hana ʻoki maikaʻi loa, hoʻohana nui ʻia ia ma ke ʻano he mea paahana.

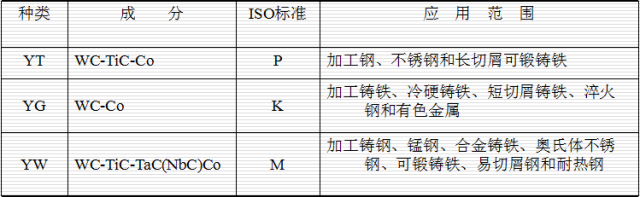

Ka hoʻokaʻawale ʻana a me ka hōʻailona ʻana i nā carbide cemented no nā mea hana ʻoki

Lahi i uhi ʻia

1) ʻO ka mea uhi o ke ʻano CVD ʻo TiC, kahi e hoʻonui ai i ka lōʻihi o nā mea hana carbide cemented e 1-3 mau manawa. ʻO ka mānoanoa o ka uhi ʻana: ʻO ka ʻoki ʻoki he blunt a kūpono i ka hoʻomaikaʻi ʻana i ke ola wikiwiki.

2) ʻO nā mea uhi o ka PVD physical vapor deposition method ʻo TiN, TiAlN, a me Ti (C, N), e hoʻomaikaʻi ana i ka lōʻihi o nā mea hana carbide cemented e 2-10 mau manawa. Ka uhi lahilahi; lihi ʻoi; He mea pono no ka hoemi ana i ka ikaika oki.

★ ka mānoanoa kiʻekiʻe o ka uhi ≤ 16um

CBN a me PCD

Cubic boron nitride (CBN) He ha'aha'a ka pa'akikī a me ka wela o ka cubic boron nitride (CBN) i ke daimana, a he ki'eki'e ka wela a me ke kinikini. No laila, kūpono ia no ka hana ʻana i ke kila paʻakikī, ka hao paʻakikī, superalloy, a me ka carbide cemented.

ʻO ke daimana Polycrystalline (PCD) Ke hoʻohana ʻia ʻo PCD ma ke ʻano he mea ʻokiʻoki, ua hoʻopaʻa ʻia ia ma ka substrate carbide cemented. Hiki iā ia ke hoʻopau i ka ʻaʻahu, ka paʻakikī kiʻekiʻe, ka non-metallic, a me ka nonferrononferrousaterials e like me ka cemented carbide, ceramics, a me ke alumini alumini silicon kiʻekiʻe.

★ ISO machine clamp blade mea hoʻohālike ★

Nā ʻāpana kila: P05 P25 P40

Ke kila kila: M05 M25 M40

Ka hao: K05 K25 K30

★ ʻOi aku ka liʻiliʻi o ka helu, ʻoi aku ka paʻakikī o ka pahi, ʻoi aku ka maikaʻi o ka pale ʻana o ka mea hana, a ʻoi aku ka ʻino o ka hopena.

★ ʻOi aku ka nui o ka helu, ʻoi aku ka palupalu o ka lau, ʻoi aku ka maikaʻi o ka hopena o ka mea paahana a me ke kūpaʻa maikaʻi ʻole.

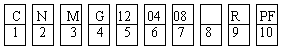

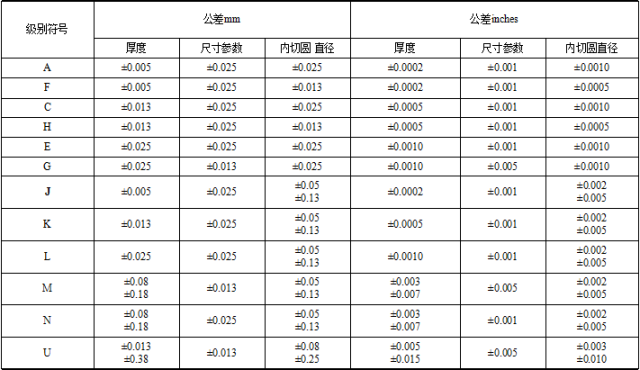

Hiki ke hoʻololi i ke kumu hoʻohālike blade a me nā lula hōʻike ISO

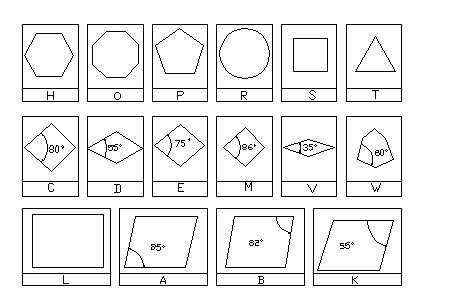

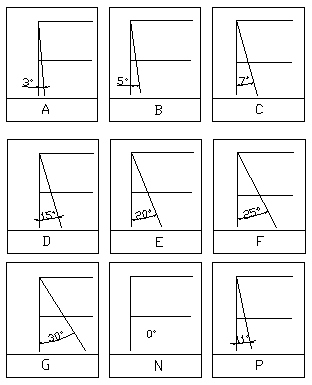

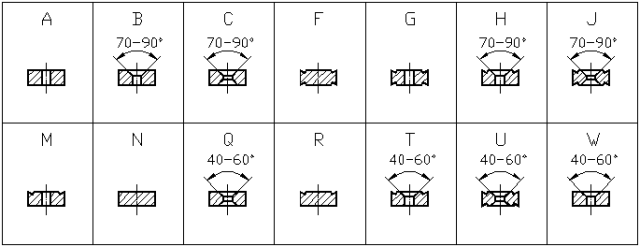

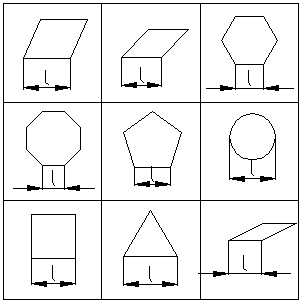

1. Code e hōʻike ana i ke ʻano o ka maka

2. Code e hōʻike ana i ke kihi hope o ka ʻoki mua

3. Code e hōʻike ana i ka hoʻomanawanui ʻana o ka lau

4. Code e hōʻike ana i ka haki ʻana a me ke ʻano paʻi o ka maka

5. Hōʻike ʻia e ka lōʻihi o ka ʻoki ʻoki

6. Code e hōʻike ana i ka mānoanoa o ka maka

7. Code e hōʻike ana i ka lihi poli a me ka huina R

ʻO ke ʻano o nā kiʻi ʻē aʻe

ʻEwalu pili i ke code e hōʻike ana i nā pono kūikawā;

Hōʻike ka 9 i ke code o ke kuhikuhi hānai; no ka laʻana, hōʻike ke code R i ka hānai ʻākau, ʻo ka helu L ka meaʻai hema, a ʻo ke code N ka hānai waena;

Hōʻike ʻo 10 i ke code o ke ʻano o ka ʻāwī wāwahi ʻana;

Hōʻike ka 11 i ke code waiwai o ka hui mea hana;

ʻoki māmā

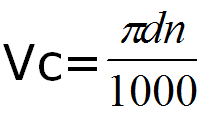

Ka helu helu o ka māmā māmā Vc:

Ma ka papa kuhikuhi:

D - ke anawaena rotary o ka mea hana a i ʻole ka mea hana, ʻāpana: mm

N - ka wikiwiki hoʻololi o ka mea hana a i ʻole ka mea hana, ʻāpana: r / min

ʻO ka māmā o ka mīkini mīkini me ka Lathe maʻamau

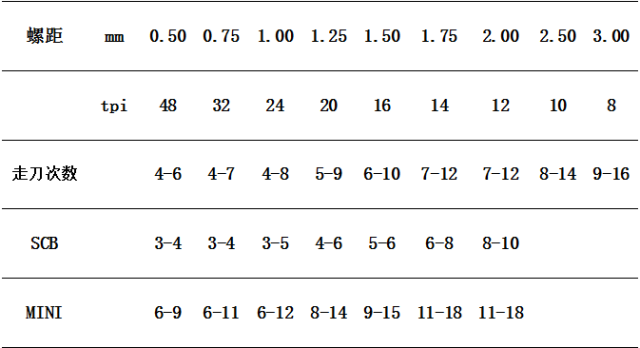

ʻO ka māmā spindle n no ka hoʻohuli ʻana i ke kaula. I ka wā e ʻoki ai i ka milo, pili ka wikiwiki o ka spindle o ka lathe e nā kumu he nui, e like me ka nui o ka pitch thread (a i ʻole ke alakaʻi) o ka mea hana, nā hiʻohiʻona hāpai a me ka hoʻohaʻahaʻa ʻana o ka mīkini hoʻokele, a me ka wikiwiki o ka interpolation thread. No laila, aia nā ʻokoʻa kikoʻī i ka wikiwiki o ka spindle no ke kaula huli no nā ʻōnaehana CNC like ʻole. ʻO kēia ke kumu no ka helu ʻana i ka wikiwiki o ka spindle i ka wā e hoʻohuli ai i nā kaula ma nā lathe CNC maʻamau.

Ma ka papa kuhikuhi:

P - ke kiko o ka milo a i ʻole ke alakaʻi o ka milo mea hana, ʻāpana: mm.

K - ka helu ʻinikua, maʻamau 80.

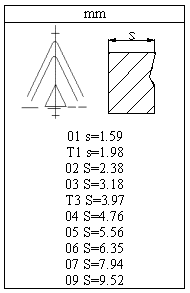

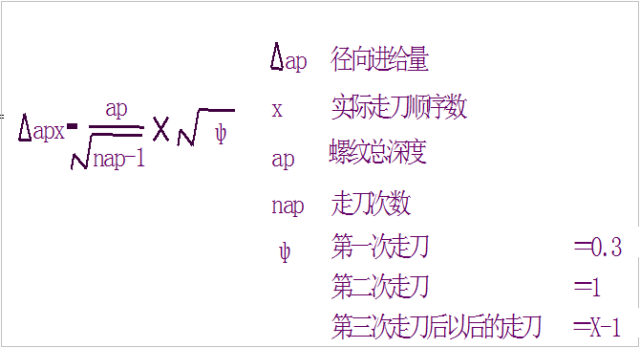

Ka helu ʻana o kēlā me kēia hohonu hānai no ke kaula mīkini

Ka helu o nā ala mea hana wili

1) ʻO ka mīkini paʻakikī

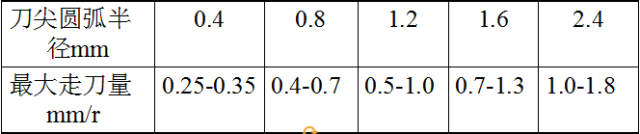

ʻO ke ʻano hoʻohālikelike hoʻohālikelike o ka hanai mīkini hana ʻino: f ʻoʻoleʻa=0.5 R

Kahi: R ------ radius arc arc mea hana mm

F ------ mea hana machining mea hanai mm

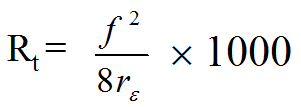

2) Hoʻopau

Ma ke kumu: Rt ------ ka hohonu µ m

F ------ Laki hānai mm/r

r ε ------ Ukuhi o ka pahu hana arc mm

E ho'oka'awale i ka huli 'ana a me ka ho'opau 'ana e like me ka nui o ka hanai a me ka 'auwa'a uha'i

F ≥ 0.36 hana ʻino

0.36 > f ≥ 0.17 hapa-hoʻopau

F < 0.17 hoʻopau mīkini

ʻAʻole ʻo ia ka mea o ka maka akā ʻo ke awāwa puʻupuʻu puʻupuʻu e pili ana i ka mīkini ʻala a hoʻopau ʻia o ka maka. ʻOi ka ʻoki ʻoki inā emi ka chamfer ma mua o 40um.

Ka manawa hoʻouna: Nov-29-2022