lawelawe hoolei make

He ʻano kūikawā ʻo Die casting no Anebon no nā makahiki he 10. Ke kōkua nei kā mākou mau lawelawe hoʻolei alumini i nā ʻenekinia, nā mea hoʻolālā huahana a me nā mea hoʻolālā e hoʻokō i kā lākou mau hoʻolālā i ke ola me nā kiʻi o ka ʻāpana kiʻi a me ka maikaʻi hilinaʻi. Hāʻawi ʻia i kā mākou ʻike ma ka ʻoihana, me kā mākou mau mea hana hou, kā mākou ʻenehana loea a me nā ʻenekini maikaʻi, a me nā limahana hana, ua hōʻoia ʻia ʻoe i ka hana maikaʻi ʻana i kāu mau ʻāpana a me nā huahana ma kahi kumukūʻai me Anebon.He ISO 9001: 2015 mea hana hoʻoheheʻe make i hoʻopaʻa ʻia i nā lawelawe hoʻoheheʻe make no nā ʻoihana alakaʻi o ka honua a me nā hui. Hoʻopili kā mākou mau lako i nā mea a pau e pono ai ka hoʻoheheʻe ʻana i ka make, ka hoʻolālā ʻana a me ka hoʻomohala ʻana e pono ai kāu ʻoihana.

He kumukūʻai nā lako hoʻolei a me nā mold, no laila hoʻohana wale ʻia ke kaʻina hana hoʻoheheʻe make no ka hana nui ʻana i nā huahana he nui. He mea maʻalahi ka hana ʻana i nā ʻāpana make-cast, ʻo ka mea maʻamau e koi wale i ʻehā mau ʻanuʻu nui, me ka haʻahaʻa o ke kumu kūʻai hoʻokahi. ʻO ka hoʻoheheʻe make he kūpono loa ia no ka hana ʻana i ka nui o nā mea hoʻoheheʻe liʻiliʻi a me ka liʻiliʻi, no laila ʻo ka die casting ka mea i hoʻohana nui ʻia i nā kaʻina hoʻolei like ʻole. Hoʻohālikelike ʻia me nā ʻenehana hoʻolei ʻē aʻe, ʻoi aku ka palahalaha o ka ʻili make-cast a ʻoi aku ka nui o ke ʻano kūlike.

He aha ka Die Casting?

ʻO ka hoʻoheheʻe make he hana hoʻoheheʻe metala i hōʻike ʻia e ka hoʻohana ʻana i kahi lua mold e hoʻopili i ke kaomi kiʻekiʻe i ka metala i hoʻoheheʻe ʻia. Hoʻohana pinepine ʻia nā ʻōpala mai nā ʻāpana ikaika kiʻekiʻe, ʻo kekahi o ia mau mea e like me ka injection molding. ʻO ka hapa nui o nā mea hoʻoheheʻe make he hao ʻole, e like me ka zinc, copper, aluminika, magnesium, lead, tin, a me nā alloys lead-tin a me nā alloys ʻē aʻe. Ma muli o ke ʻano o ka hoʻoheheʻe ʻana, pono ka mīkini hoʻoheheʻe make keʻena anuanu a i ʻole ke keʻena wela wela.

Nā hiʻohiʻona

ʻO ka hoʻoheheʻe make he ʻano hana hoʻoheheʻe ʻia kahi e ninini ʻia ai ka wai i hoʻoheheʻe ʻia i loko o kahi keʻena kaomi, hoʻopiha ʻia kahi lua o kahi pahu kila i ka wikiwiki kiʻekiʻe, a hoʻopaʻa ʻia ka wai i hoʻoheheʻe ʻia ma lalo o ke kaomi e hana i kahi hoʻolei. ʻO nā hiʻohiʻona nui o ka hoʻoheheʻe make e hoʻokaʻawale iā ia mai nā ʻano hana hoʻoheheʻe ʻē aʻe he kiʻekiʻe kiʻekiʻe a me ka wikiwiki kiʻekiʻe.

1. Hoʻopiha ka metala i hoʻoheheʻe ʻia i ka lua ma lalo o ke kaomi a crystallize ma kahi kiʻekiʻe. ʻO ke kaomi maʻamau he 15-100 MPa.

2 . Hoʻopiha ka wai metala i ka lua i ka wikiwiki kiʻekiʻe, maʻamau ma 10-50 m / s, a hiki i kekahi ke ʻoi aku ma mua o 80 m / s, (ka laina laina ma o ka ingate i loko o ka lua - ingate wikiwiki), no laila ʻoi aku ka nui o ka manawa hoʻopiha o ka metala hoʻoheheʻe. pōkole, a hiki ke hoʻopiha i ka lua ma kahi o 0.01-0.2 kekona (e pili ana i ka nui o ka hoʻolei ʻana).

ʻO ka make-casting kahi ʻano hoʻolei pololei. ʻO nā ʻāpana hoʻoheheʻe make i hoʻolei ʻia e ka make-casting, loaʻa nā ʻae ʻano liʻiliʻi liʻiliʻi a me ka pololei ʻili kiʻekiʻe. I ka hapanui o nā hihia, hiki ke hui ʻia nā ʻāpana make me ka huli ʻole. Hiki ke hoʻolei pololei ʻia nā ʻāpana.

He aha nā pōmaikaʻi o nā lawelawe hoʻoheheʻe make?

Hāʻawi kā mākou hana hoʻoheheʻe make kipi i nā pono koʻikoʻi, me:

l Hoʻopilikino: He kōkua ia i ka hoʻokō ʻana i nā hoʻolālā paʻakikī a me nā ʻano e maʻalahi ai ka hoʻopilikino ʻana i nā castings i nā kaʻina hana kikoʻī.

ll Ke kumukuai haahaa

lll Kiekie pono

llll Nui-hana a me ka corrosion-pale

Ma ke ʻano he mea hana make-casting, hāʻawi ʻo Anebon Die Casting i ka hui piha a me ka hoʻāʻo ʻana i nā ʻāpana make a me nā huahana. Inā makemake ʻoe i nā ʻāpana kūikawā e like me ka alumini die casting a i ʻole ka hoʻolei ʻana i ka vacuum die casting, a i ʻole makemake e lilo i prototype o kahi ʻāpana hou, hiki iā ʻoe ke loaʻa kahi ʻike lawelawe piha i kā mākou hale hana.

Material

ʻO ka metala a mākou i hoʻohana ai no ka hoʻoheheʻe make, ʻo ia ka zinc, ke keleawe, ke aluminika, ka magnesium, ke kēpau, ka tin, a me nā alloys lead-tin, a pēlā aku. ʻO nā hiʻohiʻona o nā metala like ʻole i ka wā o ka hoʻoheheʻe ʻana penei:

•Zinc: ʻO ka metala make maʻalahi loa, ʻoi aku ka maikaʻi i ka wā e hana ana i nā ʻāpana liʻiliʻi, maʻalahi ke kapa, ka ikaika compressive kiʻekiʻe, ka plasticity kiʻekiʻe, a me ke ola hoʻolei lōʻihi.

•Aluminum: ʻO ke kūlana kiʻekiʻe, ka hana paʻakikī a me ka hoʻoheheʻe ʻana i ka paia lahilahi me ke kūpaʻa kiʻekiʻe, ke kūpaʻa corrosion kiʻekiʻe, nā waiwai mechanical maikaʻi, ka conductivity thermal kiʻekiʻe a me ka conductivity uila, a me ka ikaika kiʻekiʻe i nā wela kiʻekiʻe.

•Magnesium: Maʻalahi i ka mīkini, ikaika kiʻekiʻe i ke kaupaona ʻana, ka māmā o nā metala make-cast maʻamau.

•keleawe: ʻO ka paʻakikī kiʻekiʻe a me ka pale ʻana i ka corrosion ikaika. ʻO ka mea maʻamau i hoʻohana ʻia me ka make-cast me ka maikaʻi loa o nā waiwai mechanical, anti-wear a me ka ikaika kokoke i ke kila.

•Ke kēpau a me ka pi: Kiʻekiʻe kiʻekiʻe a me ka kiʻekiʻe kiʻekiʻe ka pololei pololei no nā ʻāpana pale corrosion kūikawā. No nā kumu o ke olakino lehulehu, ʻaʻole hiki ke hoʻohana ʻia kēia alloy ma ke ʻano he meaʻai a me kahi hale mālama. Hiki ke hoʻohana ʻia nā ʻāpana kepau-tin-bismuth (i kekahi manawa he keleawe liʻiliʻi) no ka hana ʻana i nā leka paʻa lima a me ka hoʻopaʻa ʻana wela i ka paʻi palapala.

Hoolei Aluminum

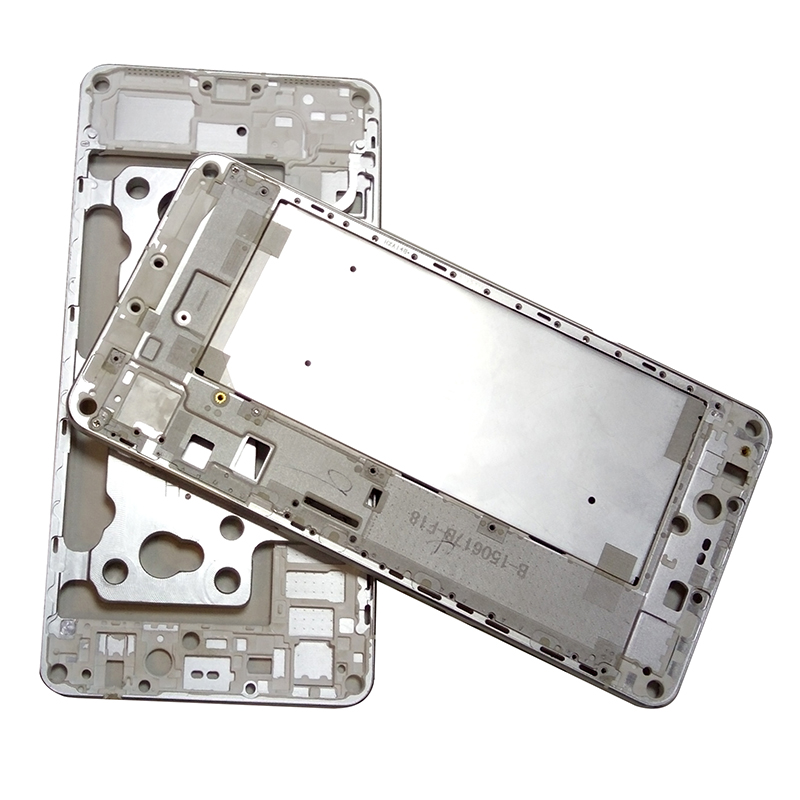

E hoolei ana i na mea pono kelepona paani

Aluminum Die Cast