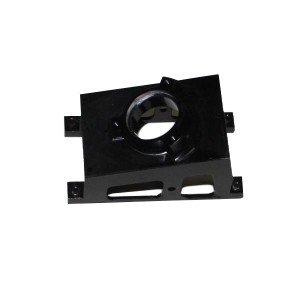

Wholesale Custom Aircraft Spare Parts Cnc Turning Service,Ome Cnc Machining Parts,Cnc Precision Turned Part

“Based on domestic market and expand overseas business” is our enhancement strategy for Wholesale Custom Aircraft Spare Parts Cnc Turning Service,Ome Cnc Machining Parts,Cnc Precision Turned Part, Welcome to set up long-term relationship with us. Best Price For Good Quality in China.

“Based on domestic market and expand overseas business” is our enhancement strategy for Aircraft Spare Parts Cnc Turning Service, Cnc Precision Turned Part, Ome Cnc Machining Parts, We follow superior mechanism to process these products that ensure optimum durability and reliability of the items. We follow latest effective washing and straightening processes that allow for us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Our company will adhere to the business philosophy of “Quality First, Sustainable and Good, People-oriented, Technological Innovation”. Efforts to keep making progress, innovation in the industry, and make every effort to be a first-class enterprise. We strive to build a scientific management model, learn rich professional knowledge, develop advanced production equipment and production technology, create first-class authentic, reasonable price, excellent service, fast delivery, and create new value for you.

The effect of plastic properties on the cutting process. The characteristics of plastic chips are smaller than that of metal. The thermal capacity of plastic is small, the thermal conductivity is poor (the thermal conductivity is only three thousandths or less of metal), and the coefficient of thermal expansion is large (1.5~ larger than metal) 20 times). Therefore, the heat generated by the friction during the cutting process is mainly transmitted to the cutter.

Tool selection:

In general, it is forbidden to straighten the slender shaft directly.

In addition, the outer turning angle of the outer turning tool can be greater than 90°.

With carbide tools, the machining quality is extremely poor and even impossible to machine.

When programming, the larger back angle, it is recommended to consider the cemented carbide, the temperature rises rapidly, and the blade is very sharp.