1. Codsiga calipers

Caliper-ku wuxuu cabbiri karaa dhexroorka gudaha, dhexroorka dibadda, dhererka, ballaca, dhumucda, farqiga tallaabo, dhererka, iyo qoto dheer ee shayga; caliper ayaa ah midka ugu badan ee la isticmaalo uguna haboon uguna badan ee loo isticmaalo wax lagu cabiro goobta wax lagu cabiro.

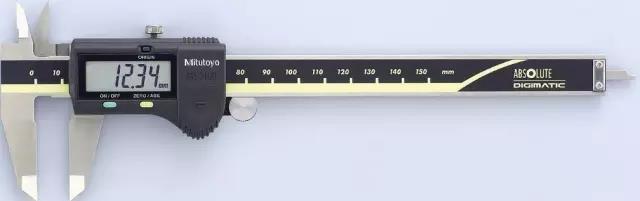

Caliper Dijital ah: Xallinta 0.01mm, oo loo isticmaalo cabbirka cabbirka oo leh dulqaad yar (saxnimo sare).

Kaarka miiska: xallinta 0.02mm, oo loo isticmaalo cabbirka cabbirka caadiga ah.

Vernier caliper: 0.02mm xallinta, loo isticmaalo cabbiraadda qallafsan.

Kahor intaadan isticmaalin caliper, ka saar boodhka iyo wasakhda warqad cad oo nadiif ah (isticmaal dusha sare ee caliper si aad u qabato warqadda cad ka dibna si dabiici ah u soo bixi; ku celi 2-3 jeer)

Marka la cabbirayo wax lagu cabbiro, oogada cabbiraadda cabbiraadda waa in ay ahaataa mid la siman ama toosan xagga cabbirka shayga la cabbiray intii suurtagal ah;

Marka la isticmaalayo cabbir qoto dheer, haddii shayga la qiyaasay uu leeyahay xagal R, waxaa lagama maarmaan ah in laga fogaado xagasha R laakiin u dhow xagasha R, iyo taliyaha qoto dheer waa inuu ahaadaa mid toosan oo suurtogal ah dhererka la qiyaasay;

Marka caliperku cabbiro dhululubada, waxay u baahan tahay in la rogo, qiimaha ugu badanna waxaa lagu cabbiraa qaybo:Qaybta mashiinka CNC.

Sababtoo ah inta jeer ee badan ee isticmaalka calipers, shaqada dayactirka waxay u baahan tahay inay noqoto tan ugu fiican. Ka dib maalin kasta oo la isticmaalo, waxay u baahan tahay in la nadiifiyo oo la dhigo sanduuqa. Isticmaalka ka hor, block ayaa loo baahan yahay si loo hubiyo saxnaanta caliper.

2. Codsiga mikrometerka

Kahor intaadan isticmaalin micrometer-ka, ka saar boodhka iyo wasakhda warqad cad oo nadiif ah (isticmaal mikromitirka si aad u cabbirto dusha xidhiidhka iyo dusha sare ee daboolka iyo warqadda cad ayaa ku dheggan ka dibna si dabiici ah u soo bixi, ku celi 2-3 jeer), ka dibna marooji buro si loo cabbiro xidhiidhka Marka dusha sare uu si degdeg ah ula taabto dusha sare ee furka, hagaajinta wanagsan ayaa la isticmaalaa, iyo marka labada sagxood ay si buuxda u wada xiriiraan, hagaajin eber ayaa la samayn karaa si loo cabbiro.qayb mashiin

Markaad qalabka ku cabbirayso mikrometerka, dhaqaaji gunta, oo marka ay la soo gaadho qalabka shaqada, isticmaal guntinka hagaajinta si aad u dhex gasho. Jooji oo akhri xogta shaashadda ama miisaanka markaad maqasho saddex dhagsi.

Marka la cabbirayo badeecooyinka balaastiigga ah, dusha taabashada cabbiraadda iyo daboolku si fudud ayay u taabtaan alaabta.

Markaad cabbirayso dhexroorka ulaha mikrometer, cabbir ugu yaraan laba jiho oo cabbir mikrometerka cabbirka ugu sarreeya ee qaybaha. Labada dusha sare ee xidhiidhka waa in had iyo jeer nadiif ahaadaan si loo yareeyo khaladaadka cabbirka.

3. Codsiga taliyaha dhererka

Cabbirka dhererka waxaa inta badan loo isticmaalaa in lagu cabbiro dhererka, qoto dheer, fidsanaanta, toosnaanta, xoogga saaridda, isku-duubnida, gariirka dusha sare, gariirka iliga, qoto dheer, iyo dhererka. Markaad cabbirayso, marka hore hubi baaritaanka iyo qaybaha isku xirka inay dabacsanaan yihiin.

4. Qalabka cabbiraadda saxda ah: element secondary

Cunsurka labaad waa aalad wax lagu cabbiro oo aan xidhiidh la lahayn oo leh waxqabad sare iyo saxnaan. Qaybta dareenka ee qalabka cabbiraadda si toos ah ulama xiriirto dusha sare ee qaybta la cabbiray, sidaas darteed ma jiro awood cabbirid farsamo; Cunsurka labaad waxa uu u gudbiyaa sawirka la qabtay iyada oo loo marayo xariiqda xogta kaadhka xog-helista ee kombiyuutarka iyada oo loo marayo habka saadaalinta. Waxaa lagu sawiray kormeeraha kumbuyuutarka ee software-ku: walxo joomatari oo kala duwan (dhibcood, xariiqyo, wareegyo, qaanso, ellipses, leydi), fogaan, xaglo, isgoysyo, dulqaadka joomatari (wareeg, toosnaan, barbardhig, toosan) Darajo, u janjeedhin, booska, xooga saarida , summetry), iyo wax-soo-saarka CAD ee sawir-gacmeedka 2D. Koontaroolka shaqada waa la arki karaa, oo qaabka dusha sare ee workpiece-ka waa la qiyaasi karaa.CNC

5. Qalabka cabbiraadda saxda ah: saddex-cabbir

Astaamaha curiyaha saddex-geesoodka ah waa saxsanaan sare (ilaa heerka μm), caalaminimada (waxay bedeli kartaa noocyo kala duwan oo qalab cabbiraadda dhererka ah), waxaa loo isticmaali karaa in lagu cabbiro dhinacyada joomatari (marka lagu daro walxaha uu curiyaha labaad cabbiri karo. Waxa kale oo ay cabbiri kartaa dhululubada iyo kooyadaha), Qaabka iyo dulqaadka booska (marka lagu daro qaabka iyo dulqaadka booska ee lagu qiyaasi karo walxaha labaad, oo ay ku jiraan cylindricity, flatness, profile line, profile surface, coaxial, oogada adag, ilaa inta baaritaanka saddex-geesoodka ah ee la taaban karo, cabbirkiisa joomatari, booska labada dhinac, muuqaalka dusha sare waa la qiyaasi karaa; iyo awoodaha dhijitaalka ah ee aad u wanaagsan, waxa ay noqotay qayb muhiim ah oo ka mid ah habaynta caaryada casriga ah iyo wax soo saarka iyo hubinta tayada Macnaha, qalab wax ku ool ah.

We are a reliable supplier and professional in CNC service. If you need our assistance, please get in touch with me at info@anebon.com.

Anebon Metal Products Limited waxay bixin kartaa mishiinada CNC, shubista dhinta, adeegyada mishiinada biraha, fadlan xor u noqo inaad nala soo xidhiidho.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Waqtiga boostada: Abriil-13-2020