HV, HB, iyo HRC waa dhammaan cabbiraadaha qallafsanaanta ee loo isticmaalo baadhista alaabta. Aynu kala saarno:

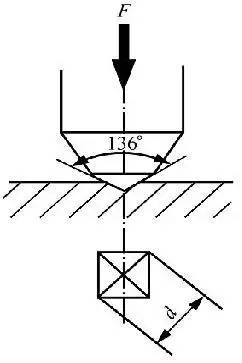

1)HV Hardness (Vickers Hardness)HV-e engegnaanta waa cabbirka caabbinta shaygu gelinta. Waxaa lagu go'aamiyaa iyada oo la adeegsanayo culeys la yaqaan oo dusha sare ah ee walxaha iyada oo la adeegsanayo dheeman dheeman ah oo lagu cabbirayo xajmiga ka soo baxa. Adkeydka HV waxaa lagu muujiyaa unugyo Vickers adag (HV) waxaana badanaa loo isticmaalaa alaabada khafiifka ah, dahaarka, iyo qaybo yaryar.

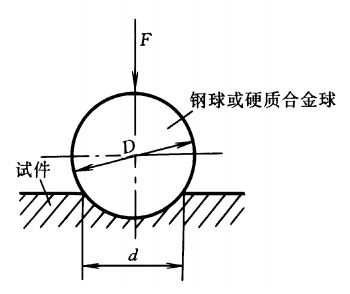

2)HB Hardness (Brinell Hardness)HB-engegnaanta waa cabbir kale oo lagu cabbiro iska caabbinta shaygu gelinta. Waxa ay ku lug leedahay in lagu dabaqo rar la og yahay walxaha iyada oo la isticmaalayo kubbadda birta qallafsan iyo cabbiraadda dhexroorka galitaanka ka dhalanaya. Adkeydka HB waxa lagu muujiyaa unugyo qallafsanaanta Brinell (HB) waxaana inta badan loo adeegsadaa agabka waaweyn iyo kuwa ka waaweyn, oo ay ku jiraan biraha iyo alaabooyinka.

3)HRC Hardness (Rockwell Hardness): Engegnaanta HRC waa cabbirka caabbinta shaygu gelinta ama dhexgalka. Waxay isticmaashaa miisaanyo kala duwan (A, B, C, iwm) oo ku salaysan habka tijaabada ee gaarka ah iyo nooca gelinta la isticmaalo (cone dheeman ama kubbadda birta adag ee adag). Miisaanka HRC waxaa caadi ahaan loo isticmaalaa cabbiraadda adayga walxaha macdanaha ah. Qiimaha qallafsanaanta waxa loo metelayaa tiro ku jirta miisaanka HRC, sida HRC 50.

Miiska isbarbardhigga qalafsanaanta HV-HB-HRC ee sida caadiga ah loo isticmaalo:

| Miiska isbarbardhigga birta adag ee birta caadiga ah (qiyaastii awoodda beddelka) | ||||

| Kala soocida adkaanta | Xoog xajin N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690kii |

| 50 | 75.8 | 509 | 488 | 1720kii |

| 50.5 | 76.1 | 517 | 494 | 1750kii |

| 51 | 76.3 | 525 | 501 | 1780kii |

| 51.5 | 76.6 | 534 | - | 1815kii |

| 52 | 76.9 | 543 | - | 1850kii |

| 52.5 | 77.1 | 551 | - | 1885kii |

| 53 | 77.4 | 561 | - | 1920kii |

| 53.5 | 77.7 | 570 | - | 1955kii |

| 54 | 77.9 | 579 | - | 1995kii |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

Tilmaamaha Beddelka Qiyaasta HRC/HB

Adaggu wuu ka sarreeyaa 20HRC, 1HRC≈10HB,

Adaggu wuu ka hooseeyaa 20HRC, 1HRC≈11.5HB.

Xusuusin: Goynta ka shaqeynta, asal ahaan waxaa loo rogi karaa si isku mid ah 1HRC≈10HB

Qallafsanaanta walxaha birta ah

Adaggu waxa loola jeedaa awoodda shay uu iskaga caabinayo qallafsanaanta gudaha, gaar ahaan qallooca balaastigga ah, galitaanka ama xoqidda. Waa tilmaame lagu cabbirayo jilicsanaanta iyo qallafsanaanta maaddada.

Marka loo eego habab kala duwan oo tijaabo ah, engegnaanta waxaa loo qaybiyaa saddex nooc.

①xoqan adkaanta. Inta badan waxaa loo isticmaalaa in lagu barbardhigo jilicsanaanta iyo qallafsanaanta macdanta kala duwan. Habka ayaa ah in la doorto ul leh hal cidhif oo adag, kan kalena jilicsan, u gudub walxaha lagu tijaabinayo usha, lana go'aamiyo adkaanta walxaha lagu tijaabinayo iyada oo loo eegayo booska xoqitaanka. Sida tayada leh, walxaha adag waxay sameeyaan xoqin dheer iyo walxaha jilicsan waxay sameeyaan xoqin gaaban.

②Adkaanshaha galitaanka. Inta badan loo isticmaalo walxaha birta ah, dariiqa waa in la isticmaalo culeys gaar ah si loo cadaadiyo soo gelista la cayimay ee shayga la tijaabinayo, oo la barbar dhigo jilicsanaanta iyo qallafsanaanta walxaha lagu tijaabiyo cabbirka qallooca balaastigga maxalliga ah ee dusha sare ee maadada. Marka loo eego kala duwanaanshaha gelinta, rarka iyo muddada rarka, waxaa jira noocyo badan oo qallafsanaan, oo ay ku jiraan adkaanta Brinell, Rockwell engegnaanta, Vickers engegnaanta iyo microhardness.

③Adag soo laabashada Inta badan loo isticmaalo walxaha birta ah, dariiqa ayaa ah in la sameeyo dubbe yar oo gaar ah oo si xor ah uga soo dhacaya dherer gaar ah si ay saameyn ugu yeelato muunadda walxaha la tijaabinayo, oo la isticmaalo qadarka tamarta cadaadiska ee kaydsan (ka dibna la sii daayo) muunadda inta lagu jiro saamaynta (iyada oo loo marayo soo celinta dubbaha yar) cabbirka dhererka bood) si loo go'aamiyo adkaanta walxaha.

Adayga Brinell ee ugu caansan, qallafsanaanta Rockwell iyo adkaanta Vickers ee qalabka birta ayaa iska leh qallafsanaanta. Qiimaha qallafsanaantu waxay muujinaysaa awoodda maaddadu u leedahay inay ka hortagto qallafsanaanta caagga ah ee ay keento shay kale oo lagu cadaadiyo; C) si loo cabbiro adkaanta, iyo qiimaha qallafsanaantu waxay ka dhigan tahay cabbirka shaqada qallafsanaanta laastikada ee birta.

Brinell Hardness

Isticmaal kubbad bir ah oo la bakhtiiyey ama kubbadda daawaynta adag ee dhexroorka D ah sida soo geliye ahaan, ku cadaadi dusha sare ee qaybta tijaabada oo leh xoogga tijaabada F, ka dib wakhti cayiman, ka saar xoogga tijaabada si aad u hesho dhexgalka leh dhexroorka d. U qaybi xoogga tijaabada dhinaca dusha sare ee galitaanka, qiimaha ka dhashayna waa qiimaha qallafsanaanta Brinell, iyo calaamadda waxaa matalaya HBS ama HBW.

Farqiga u dhexeeya HBS iyo HBW ayaa ah faraqa u dhexeeya gudaha gudaha. HBS macneheedu waxa weeye in hindisuhu yahay kubbad bir ah oo adag, kaas oo loo isticmaalo in lagu cabbiro alaabta leh qiimaha engegnaanta Brinell ee ka hooseeya 450, sida birta khafiifka ah, birta cawlan iyo birta aan birta ahayn. HBW macneheedu waxa weeye in geliyahu uu yahay kaarbiid sibidh ah, kaas oo loo isticmaalo in lagu cabbiro alaabta leh qiimaha qallafsanaanta Brinell ee ka hooseeya 650.

Isla xannibaadda tijaabada, marka shuruudaha kale ee imtixaanku ay isku mid yihiin, natiijooyinka labada imtixaan way kala duwan yihiin, qiimaha HBW inta badan wuu ka weyn yahay qiimaha HBS, mana jiro xeer tiro ah oo la raaco.

Kadib 2003dii, dalkaygu waxa uu si la mid ah u qaatay halbeegyada caalamiga ah, waxa la joojiyay tusayaasha kubbada birta, iyo dhamaan madaxyada kubbada carbide la isticmaalay. Sidaa darteed, HBS waa la joojiyay, waxaana HBW loo isticmaalaa in lagu matalo calaamadda qallafsanaanta Brinell. Xaalado badan, adkaanta Brinell waxaa lagu muujiyaa kaliya HB, iyadoo la tixraacayo HBW. Si kastaba ha ahaatee, HBS ayaa weli mar mar lagu arkaa waraaqaha suugaanta.

Habka cabbiraadda qallafsanaanta Brinell wuxuu ku habboon yahay birta shubka ah, alloysyada aan birta ahayn, birta la jeexjeexay iyo kuwa la demiyay oo kala duwan, kuma habboona in la tijaabiyo muunado amacnc rogid qaybokuwaas oo aad u adag, aad u yar, aad u dhuuban, ama aan ogolayn in la soo galo waaweyn oo dusha sare ah.

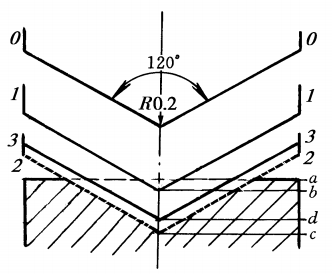

Rockwell Hardness

Isticmaal koofiyad dheeman ah oo leh xagal koor ah oo ah 120° ama Ø1.588mm iyo Ø3.176mm kubbadaha birta la demiyo sida soo gelida iyo culayska si aad ula kaashato. Culayska bilowga ah waa 10kgf wadarta guudna waa 60, 100 ama 150kgf (taasi waa rarkii hore iyo culayska ugu weyn). Adkeydka waxaa lagu muujiyay farqiga u dhexeeya qoto dheer ee gelinta marka culeyska ugu weyn la saaro iyo qoto-dheeraanta gelinta marka culeyska ugu weyn la hayo iyo qoto-dheeraanta dhexgalka ee hoos yimaada culeyska bilowga ah ka dib marka la isticmaalo wadarta guud.

Tijaabada qallafsanaanta Rockwell waxay isticmaashaa saddex xoog oo tijaabo ah iyo saddex indentors. Waxaa jira 9 isku-dar ah oo iyaga ka mid ah, oo u dhiganta 9 miisaan ee adkaanta Rockwell. Codsiga 9-kan taliye wuxuu daboolayaa ku dhawaad dhammaan qalabka birta ah ee sida caadiga ah loo isticmaalo. Waxaa jira saddex HRA, HRB iyo HRC oo inta badan la isticmaalo, kuwaas oo HRC ay tahay tan ugu isticmaalka badan.

Shaxda qeexida adag ee Rockwell ee sida caadiga ah loo isticmaalo:

| Adag | | | Adag | |

| | | | | Carbide, carbide, |

| | | | | Annealed, birta caadiga ah, daawaha aluminium |

| | | | | bir qallafsan, bir la demiyay oo dabcay, qoto dheer |

Baaxadda isticmaalka miisaanka HRC waa 20 ~ 70HRC. Marka qiimaha qallafsanaantu uu ka yar yahay 20HRC, sababtoo ah koonkaaluminium cnc qayb machiningIndenenter aad buu u cadaadiyaa, dareenka ayaa yaraada, iyo miisaanka HRB waa in la isticmaalaa bedelkeeda; marka adkaanta muunada ay ka weyn tahay 67HRC, cadaadiska cidhifka wax geliya waa mid aad u weyn, dheemankuna si fudud ayaa loo dhaawacaa. Nolosha qofka wax geliya si weyn ayaa loo soo gaabin doonaa, sidaa darteed cabbirka HRA waa in guud ahaan la isticmaalo beddelkeeda.

Tijaabada adag ee Rockwell waa mid fudud, degdeg ah, iyo soo gelid yar, oo waxay tijaabin kartaa oogada alaabta la dhammeeyey iyo qaybo adag oo khafiif ah. Sababo la xiriira gelitaanka yar, ee alaabta leh qaab-dhismeedka aan sinnayn iyo adaygga, qiimaha qallafsanaan aad u weyn, iyo saxsanaan ma aha sida sare sida Brinell engegan. Adag ee Rockwell waxaa loo isticmaalaa in lagu go'aamiyo adkaanta birta, biraha aan birta ahayn, alloys adag, iwm.

Vickers Hardness Vickers Harness

Mabda'a cabbiraadda adkaanta Vickers waxay la mid tahay ta Brinell. Isticmaal dheeman labajibbaaran ee ahraamta ah oo leh xagal ka mid ah 136° si aad ugu cadaadiso dusha shayga leh xoog tijaabo ah oo F, oo ka saar xoogga tijaabada ka dib markaad ilaaliso wakhtiga la cayimay. Adkeydka waxaa lagu muujiyay cadaadiska celceliska ah ee aagga dusha halbeegga ee galitaanka haramka labajibbaaran. Qiimaha, calaamada calaamaduhu waa HV.

Cabbirka cabbirka adkaanta Vickers waa weyn yahay, wuxuuna cabbiri karaa agab adag oo u dhexeeya 10 ilaa 1000HV. Gelitaanku waa yar yahay, waxaana guud ahaan loo isticmaalaa in lagu cabbiro walxaha khafiifka ah iyo lakabyada adag ee dusha sare sida carburizing iyo nitriding.

Leeb Hardness Leeb Adag

Isticmaal jidhka saamaynta leh oo leh cuf gaar ah oo madaxa kubbadda tungsten carbide si aad u saamayso dusha qaybta tijaabada ee hoos timaad xoog gaar ah, ka dibna dib u soo celi. Sababtoo ah qallafsanaanta kala duwan ee alaabta, xawaaraha dib u soo celinta ka dib saameynta sidoo kale waa ka duwan yahay. Magnet joogto ah ayaa lagu rakibay aaladda saamaynta leh. Marka jirku kor iyo hoos u dhaqaaqo, gariiradiisa durugsan waxay keeni doontaa calaamad koronto oo u dhiganta xawaaraha, ka dibna waxay u rogi doontaa qiimaha qallafsanaanta Leeb iyada oo loo marayo wareegga elektaroonigga ah. Astaanta waxaa lagu calaamadeeyay sida HL.

Tijaabada qallafsanaanta Leeb uma baahna wax la shaqayn karo, dareemahiisuna waxa uu u yar yahay sida qalinka oo kale, kaas oo si toos ah gacanta loogu shaqayn karo, si fududna loo ogaan karo haddii uu yahay mid weyn, hawl culus ama mid shaqo oo leh cabbir joomatari oo kakan.

Faa'iidada kale ee engegnaanta Leeb waa in ay aad u yar tahay waxyeellada dusha sare ee alaabta, mararka qaarkoodna waxaa loo isticmaali karaa tijaabo aan burburin; waa mid u gaar ah imtixaanada adkaanta ee jihooyinka oo dhan, meelaha cidhiidhiga ah iyo kuwa gaarka ahqaybaha aluminium.

Anebon wuxuu u hoggaansamaa mabda'a "Daacad ah, hawlkar ah, ganacsi leh, hal-abuur leh" si uu u helo xalal cusub si joogto ah. Anebon waxa uu u arkaa rajada, guushu sida guusheeda gaarka ah. Anebon ha dhiso gacanta mustaqbalka barwaaqaysan ee gacanta ee qaybaha mashiinnada naxaasta ah iyo qaybaha cnc ee isku dhafan / agabka shaabadda. Anebon hadda waxay leedahay sahayda alaabada oo dhamaystiran sidoo kale qiimaha iibinta ayaa ah faa'iidadayada. Ku soo dhawoow inaad wax ka waydiiso alaabta Anebon.

Alaabooyinka Isbeddelka ee Shiinaha CNC Qaybta Mashiinka iyo Qaybta Saxda ah, runtii waa in mid kasta oo ka mid ah walxahan ay daneynayaan adiga, fadlan nala soo socodsii. Anebon wuxuu ku faraxsanaan doonaa inuu ku siiyo oraah marka la helo mid ka mid ah tilmaamihiisa faahfaahsan. Anebon waxay haysataa injineeradayada R&D ee khaaska ah si ay u buuxiyaan shuruudaha. Anebon waxa ay rajaynaysaa in aad dhawaan hesho su'aalahaaga waxana aad rajaynaysaa in aad fursad u hesho in aad mustaqbalka kula shaqeyso. Ku soo dhawoow si aad u eegto ururka Anebon.

Waqtiga boostada: Meey-18-2023