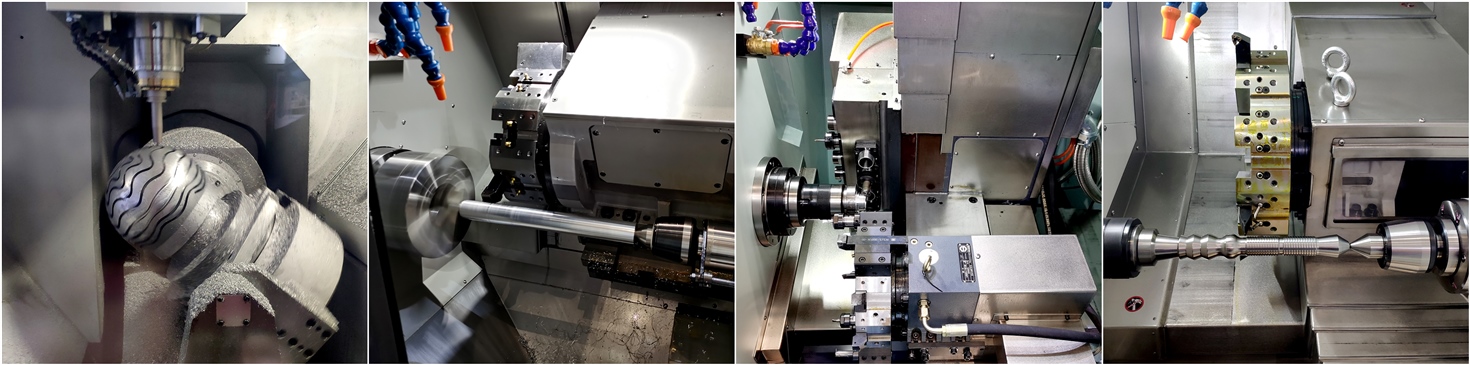

Small Components Made By CNC milling

Our CNC machining process can produce customized prototypes and final-use production parts within 1 day. We use 3-axis milling and 5-axis indexing milling processes to manufacture parts with more than 30 engineering grade plastics and metals. With machined production parts, in addition to first article inspection (FAI) reports, material certification, and other finishing options such as anodizing and chromate plating, you can also get more competitive prices in large quantities.

Features:

1. Process precision CNC stainless steel parts in strict accordance with customer drawings, packaging and quality requirements

2. Tolerance: it can be kept within +/- 0.005mm

3. The most advanced CMM tester ensures quality

4. Experienced technical engineers and well-trained workers

5. Prompt delivery. Fast and professional service

6. Provide professional advice to customers in the process of customer design to save costs.

| Process | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Surface treatment | Polishing,sandblasting,anodizing,

brushing,powder coating,electroplating, silk-screen. |

| Tolerance | 0.01-0.05mm can also be customized |

| Applied Software | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE. |

| Dimension | As customers' request. |

| Delivery time | 7-30 days after receive the pre-payments. |

| Packaging | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Or according to customers' requirement. |

| 4 Axis Cnc Machining | Mechanical Component | Cnc High Speed Milling |

| 4 Axis Machining | Stainless Parts | Cheap Cnc Milling Service |

| Stainless Steel Cnc | 5 Axis Cnc Machining Services | Cnc Rapid |