1. Z-direction tool set of machining center

E masani lava e tolu auala mo le faʻatulagaina o meafaigaluega Z-direction o nofoaga autu o masini:

1) Fa'atonu meafaigaluega i luga ole masini 1

O lenei faiga fa'atulagaina meafaigaluega o le fa'asolosolo fa'asolosolo le va o le va o meafaigaluega ta'itasi ma le mea faigaluega i totonu o le masini fa'amaopoopo faiga e ala i mea faigaluega i le taimi.CNC machining vaegamaCNC vaega liliu. O ona laasaga fa'atino fa'apitoa e fa'apea.

(1) Fa'atusatusa le umi o meafaigaluega, saili le meafaigaluega sili ona umi e fai ma mea faigaluega fa'asinomaga, fa'atino le fa'atulagaina o meafaigaluega fa'atonu-Z, ma fa'aoga le tau fa'atulagaina o meafaigaluega (C) i le taimi nei o le tau Z o le faiga fa'amaopoopo mea faigaluega, ma H03= 0 i le taimi nei.

(2) Faʻapipiʻi meafaigaluega T01 ma T02 i luga o le spindle, ma fuafua le tau o le A ma le B e avea ma tau taui umi e ala i le seti meafaigaluega. (O lenei metotia e le fuaina sa'o ai taui meafaigaluega, ae e ese mai le metotia 3 e fuafuaina e ala i le seti meafaigaluega fa'asolosolo.)

(3) Faatumu le tau fuafuaina o le umi o taui (le umi o le meafaigaluega umi toese le umi o meafaigaluega) i totonu o le itulau seti. O faʻailoga lelei ma faʻailoga e faʻamoemoeina e le G43 ma le G44 i le polokalame, ma i le taimi nei e masani ona faʻatusalia e G44H—. A faʻaaoga le G43, o le umi o taui o se tau le lelei.

O lenei metotia faʻatulagaina meafaigaluega e maualuga le faʻatulagaina o meafaigaluega ma le saʻo, ma faʻaitiitia tupe teufaafaigaluega, ae e le faigofie le tusiaina o pepa faʻagasologa, lea ei ai se aafiaga patino i le faʻatulagaina o gaosiga.

2) Fa'atonu meafaigaluega i luga ole masini 2

O laasaga faʻatino faʻapitoa o lenei metotia faʻatulagaina meafaigaluega e faʻapea:

(1) O le fa'atulagaina o le fa'atonuga o le XY e tutusa ma le taimi muamua, fa'aofi le tau fa'asoa i le mea XY i le G54, ma fa'atulaga le mea Z i le zero.

(2) Suia le T1 o loʻo faʻaaogaina mo le faʻaogaina ma le 'au autu, faʻaoga le poloka poloka e faʻaoga ai le Z, faitau le Z value Z1 o le masini masini faʻamaopoopo faiga pe'ā talafeagai le faʻamau, ma faʻatumu le umi tau taui H1 pe a uma. toese le maualuga o le fua poloka.

(3) Faʻapipiʻi le T2 i luga o le 'au autu, faʻaoga i se poloka poloka, faitau le Z2, toese le maualuga o le poloka poloka ma faʻatumu le H2.

(4) I se fa'atusa, fa'aoga poloka poloka e fa'aoga ai tino meafaigaluega uma, ma fa'atumu le Hi pe a uma ona toesea le maualuga o poloka poloka.

(5) A'o fa'apolokalameina, fa'aoga auala nei e totogi ai:

T1;

G91 G30 Z0;

M06;

G43 H1;

G90 G54 G00 X0 Y0;

Z100;

...(O loʻo taua i lalo le faʻaogaina o meafaigaluega-pass o Nu. 1 meafaigaluega seia oʻo i le iuga)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

Z100;

…(O mea uma o lo'o fa'agaioia ile naifi Nu.2)

…M5;

M30;

3) Fa'ata'ita'iina o mea faigaluega e leai se masini + fa'atulagaina o meafaigaluega i luga ole masini

O lenei metotia o le faʻatulagaina o meafaigaluega o le faʻaaogaina lea o le mea faigaluega presetter e fua saʻo ai le axial ma le radial dimensions o meafaigaluega taitasi i fafo atu o le meafaigaluega masini, fuafua le umi tau taui o meafaigaluega taitasi, ona faʻaaoga lea o le meafaigaluega sili ona umi i luga o le masini meafaigaluega e faatino ai le Z To. seti meafaigaluega, fuafua le faiga faamaopoopo mea faigaluega.

O lenei metotia faʻatulagaina meafaigaluega e maualuga le saʻo ma le lelei o meafaigaluega, ma e faigofie mo le saunia o pepa faʻagasologa ma le faʻatulagaina o gaosiga, ae o le tupe teufaafaigaluega e matua tele.

2. Tulaga o fa'amaumauga fa'atulagaina meafaigaluega

(1) O faʻamaumauga faʻatulagaina meafaigaluega na maua e tusa ai ma faʻagaioiga o loʻo i luga, o lona uiga, o le X, Y, ma le Z o tau o le amataga o le faʻaogaina o le polokalama faʻapipiʻi i le masini faʻapipiʻi masini, e tatau ona tuʻuina ma le lima i le G54 ~ G59 mo le teuina. O laasaga fa'agaioiga e fa'apea:

①Oomi le ki.

②Oomi le ki fa'ailo e alu i leCNC milling vaegamaCNC vaega liliufaiga fa'amaopoopo G54~G59 e fa'agasolo.

③Oomi【X】ki e fa'aofi ai le tau faamaopoopo X.

④Oomi le ki.

⑤Oomi 【Y】 ki e fa'aofi Y faamaopoopo tau.

⑥Oomi le ki.

⑦Oomi 【Z】 ki e fa'aulu ai le tau faamaopoopo Z.

⑧Oomi le ki.

(2) O le tau o taui meafaigaluega e masani lava ona tuʻuina i totonu o le masini masini aʻo leʻi faʻapipiʻiina le polokalame e le MDI (manual data input). O laasaga fa'agaioiga lautele e fa'apea:

①Oomi le ki.

②Oomi le ki fa'agaioiga o le fa'ailo i le numera o taui.

③Tulaga tau taui.

④Oomi le ki.

3. Tofotofoga auala tipi mo le seti naifi

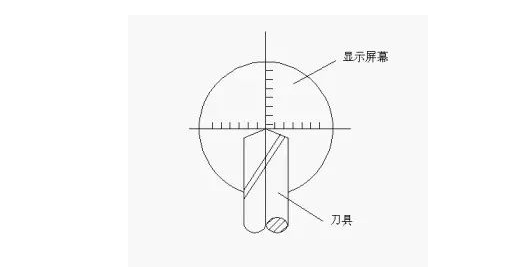

O le faʻataʻitaʻiga o le tipiina o se metotia faʻapipiʻi meafaigaluega faigofie, ae o le a tuʻu ai faʻailoga i luga o le mea faigaluega, ma e maualalo le saʻo o meafaigaluega. E fetaui lelei mo le faʻatulagaina o meafaigaluega i le taimi e faʻaogaina ai vaega. O lona fa'atulagaina o meafaigaluega e tutusa ma le masini su'e mata.

4. Fa'atulaga meafaigaluega e fua ai le telefoni

O le fa'atulagaina o meafaigaluega sa'o o le fa'ailo vili lever e maualuga, ae o lenei faiga fa'agaioiga e faigata ma e maualalo le lelei. E fetaui lelei mo le faʻatulagaina o meafaigaluega o le faʻamaeʻaina o le pu (luʻu), ae e le talafeagai mo le puʻu machining talatala.

O le auala e fa'atulaga ai meafaigaluega e fa'apea: fa'aoga le fa'avae mata'i fa'amaneta e toso mai ai le fa'ailo o le lever dial i le milo o le nofoaga autu o masini, ma fa'alatalata le ulu o le fua i le puipui o le pu (po'o luga o le cylindrical). I totonu o le mea sese, e pei o le 0.02, e mafai ona manatu o le ogatotonu o le taamilosaga o le spindle e fetaui ma le ogatotonu o le pu fuaina i le taimi nei, ma faʻapipiʻi le X ma le Y faʻamaopoopo tau i le masini faʻamaopoopo faiga i le taimi nei i le G54.

5. Fa'atulaga meafaigaluega ile itu Z

Mafaufau i le gaosiga o le seti meafaigaluega, o le pito i luga o le mea faigaluega e masani ona avea o le amataga o le Z o le faʻaogaina o mea faigaluega. Afai o le pito i luga o le vaega e fai si talatala ma e le mafai ona faʻaaogaina e pei o le faʻatulagaina o meafaigaluega, o le vise poʻo le laulau faigaluega e mafai foi ona faʻaaogaina e avea ma amataga o le Z o le faʻaogaina o mea faigaluega, ona faʻasaʻoina lea o le maualuga o le mea faigaluega. agai i luga i le G54 poʻo le faʻalauteleina o le faʻamaopoopo faiga e faʻatumu i totonu. Z-direction machine tool set e tele lava ina aofia ai Z-direction mea faigaluega faʻatulagaina meafaigaluega, meafaigaluega seti poloka poloka seti meafaigaluega ma tofotofoga tipi faiga seti meafaigaluega ma isi metotia.

6. Fa'atulagaina o meafaigaluega e fua ai le itu-Z

O le faʻatulagaina o meafaigaluega saʻo o le mea e fua ai le Z-direction e maualuga, aemaise lava pe a faʻapipiʻiina le tele o meafaigaluega i luga o le masini i le nofoaga autu o masini milling, e maualuga le faʻatulagaina o meafaigaluega, e laʻititi le tupe teufaafaigaluega, ma e talafeagai mo se vaega e tasi. faiga.

1) Z-direction mea faigaluega faʻatulagaina i le taimi e tasi-meafaigaluega masini o le nofoaga autu masini

O le faʻaogaina o meafaigaluega e tasi i totonu o se nofoaga faʻapipiʻi e tutusa ma le faʻafitauli e leai se totogi umi mo le faʻatulagaina o meafaigaluega i luga o se masini milling CNC. O laasaga nei:

(1) Toe sui le meafaigaluega o le a faʻaaogaina mo le faʻaogaina;

(2) Ave le meafaigaluega i le pito i luga o le mea faigaluega, fua le mamao i le va o le mea faigaluega ma le meafaigaluega i se meafaigaluega fua Z-direction, ma faamaumau le Z-axis faitau Z o le masini masini (mechanical) coordinate system;

(3) Toese le tau o le Z mai le maualuga o le mea e fua ai le itu-Z i le taimi nei (e pei o le 50.03mm), ona faatumu lea o le tau ua fuaina i le mea Z o le OFFSETSETTING–>coordinate system–>G54;

(4) Tamomoe G90 G54G0 X0 Y0 Z100; siaki pe sa'o le fa'aogaina

Taimi meli: Ian-09-2023