industry news

-

201, 202, 301, 302, 304 which is a good steel? | Stainless Steel Encyclopedia

Stainless steel is a popular material used in machining due to its strength, durability, and resistance to corrosion. However, it can also present challenges in the machining process due to its hardness and work-hardening tendencies. Here are some important considerations when machinin...Read more -

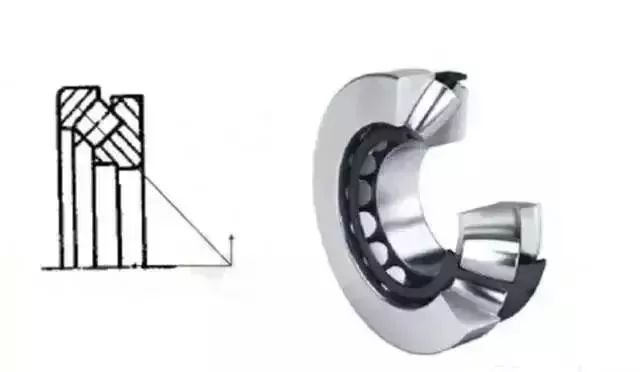

The characteristics, differences and uses of fourteen kinds of bearings | An overview of this article

What is a bearing? Bearings are parts that support the shaft, used to guide the rotational movement of the shaft, and bear the load transmitted from the shaft to the frame. Bearings are widely used and demanding supporting parts and basic parts in the machinery industry. They are the support...Read more -

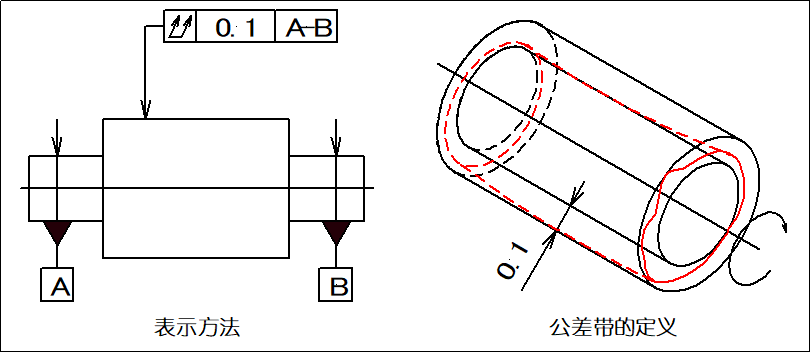

Straightness, flatness, roundness, cylindricity… Do you know all these Tolerance of Form and Position well?

Do you know what Tolerance of Form and Position is? Geometric tolerance refers to the allowable variation of the actual shape and actual position of the part from the ideal shape and ideal position. Geometric tolerance includes shape tolerance and position tolerance. Any part is co...Read more -

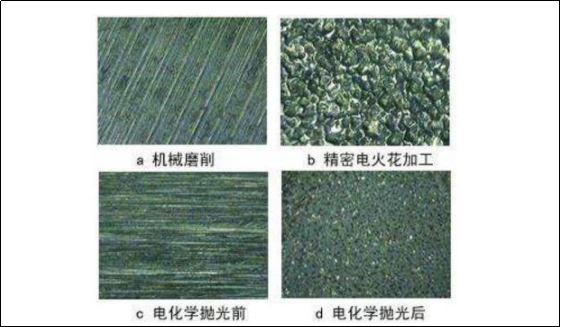

Surface Roughness Encyclopedia

1. The concept of metal surface roughness Surface roughness refers to the unevenness of small pitches and tiny peaks and valleys that a machined surface has. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic ge...Read more -

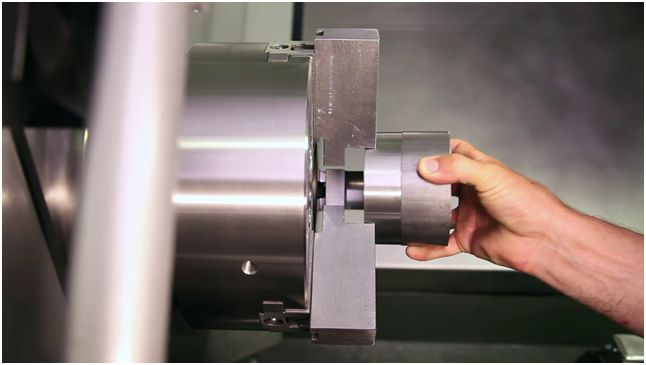

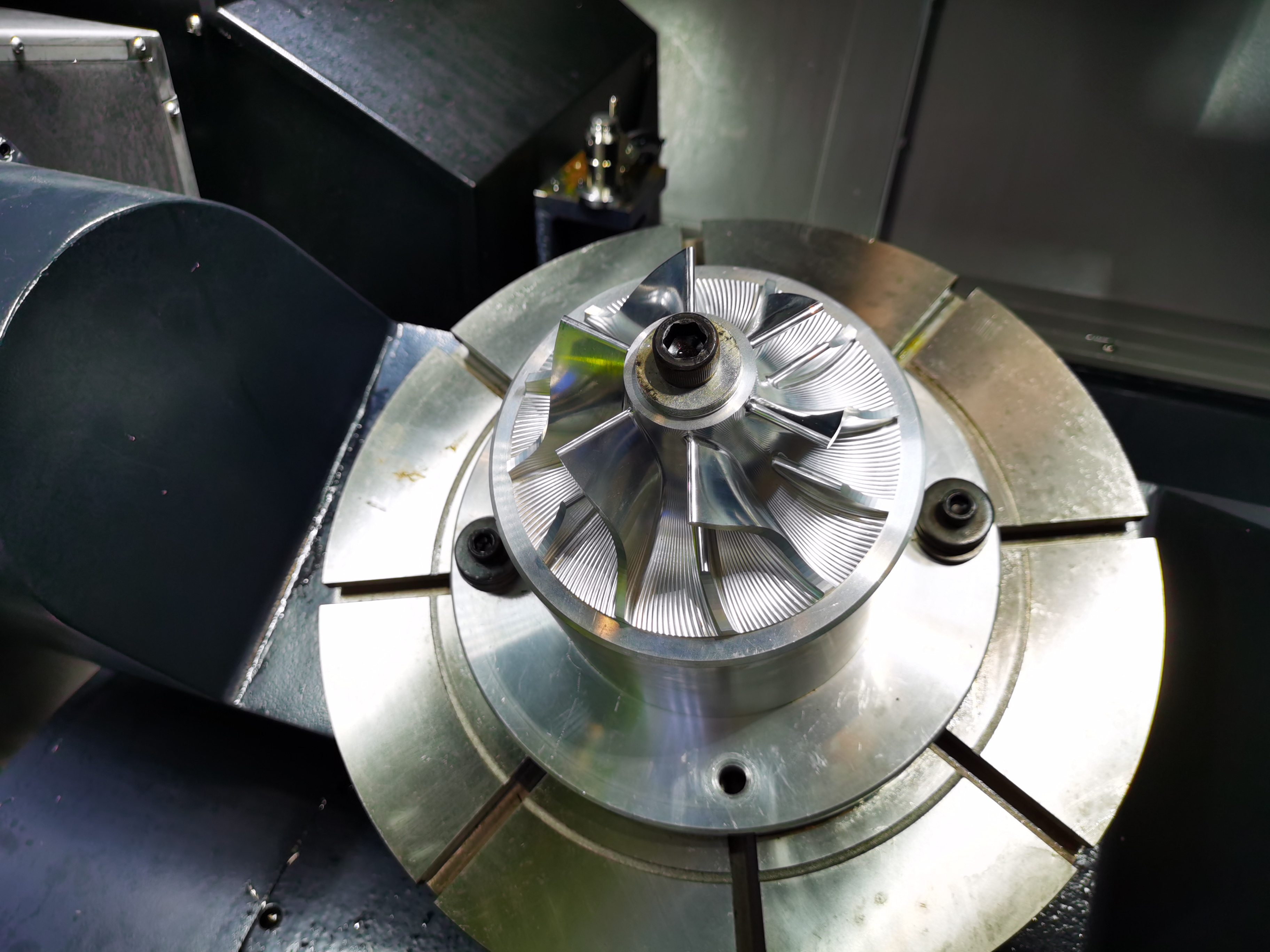

What should you do if the workpiece is deformed, pinched, or dimensionally unstable during processing?

Indispensable Fixtures for CNC Machining — Soft Jaws The soft claw can ensure the repeated positioning accuracy of the workpiece to the greatest extent, so that the centerline of the processed workpiece can completely coincide with the centerline of the spindle, and the flat surface on ...Read more -

CNC Tool Material & Selection Encyclopedia

What is a CNC tool? The combination of advanced processing equipment and high-performance CNC cutting tools can give full play to its due performance and achieve good economic benefits. With the rapid development of cutting tool materials, various new cutting tool materials have greatly impro...Read more -

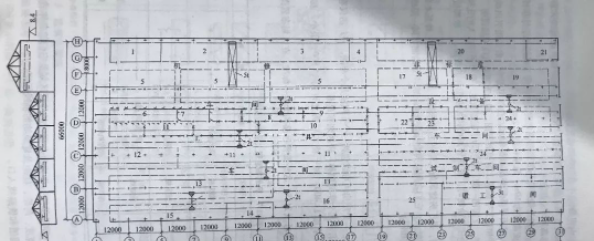

Calculation method of eccentric parts of CNC lathe

What are eccentric parts? Eccentric parts are mechanical components that have an off-center axis of rotation or an irregular shape that causes them to rotate in a non-uniform manner. These parts are often used in machines and mechanical systems where precise movements and control are required. On...Read more -

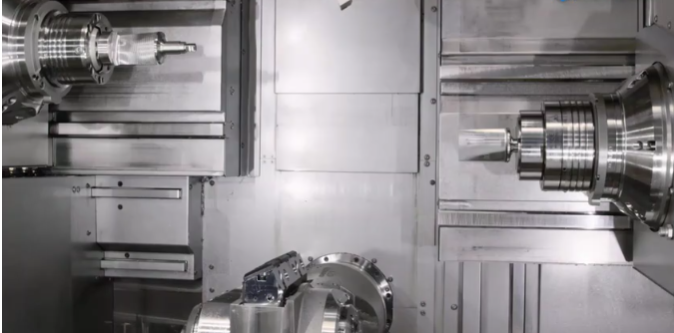

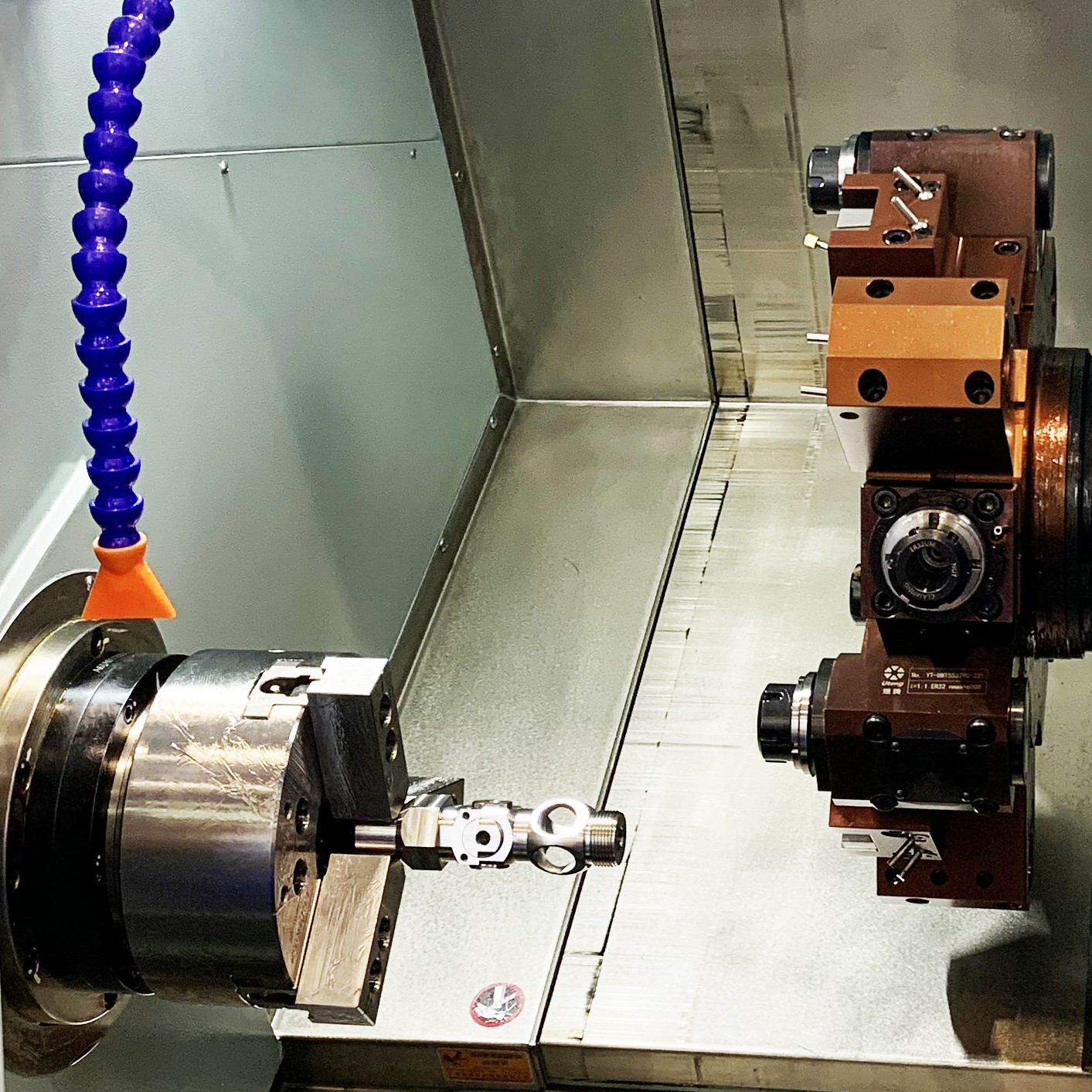

What is CNC machining?

CNC machining (Computer Numerical Control machining) is a manufacturing process that involves the use of computer-controlled machines to create precise parts and components from a variety of materials. It is a highly automated process that involves the use of CAD (Computer-Aided Design) software ...Read more -

The characteristics and differences of quenching cracks, forging cracks and grinding cracks

Quenching cracks are common quenching defects in CNC machining, and there are many reasons for them. Because heat treatment defects start from product design, Anebon believes that the work of preventing cracks should start from product design. It is necessary to correctly select materials, reason...Read more -

Process measures and operating skills to reduce deformation during CNC machining of aluminum parts!

Anebon’s other peer factories often encounter the problem of processing deformation when processing parts, the most common of which are stainless steel materials and aluminum parts with low density. There are many reasons for the deformation of custom aluminum parts, which are related to th...Read more -

CNC machining knowledge that cannot be measured by money

1 Influence on cutting temperature: cutting speed, feed rate, back cutting amount. Influence on cutting force: back cutting amount, feed rate, cutting speed. Influence on tool durability: cutting speed, feed rate, back cutting amount. 2 When the amount of back engagement doubles, the cutting forc...Read more -

The meaning of 4.4, 8.8 on the bolt

I have been doing machinery for so many years, and have processed various machining parts, turning parts and milling parts through CNC machine tools and precision equipment. There is always one part that is essential, and that is the screw. The performance grades of bolts for steel structure con...Read more