industry news

-

Discover the Essential Features of 9 Different Work Fixtures

The design of tooling fixtures is a process that is tailored to the specific requirements of a particular manufacturing process. This is done after the machining process of the parts is finalized. When developing the manufacturing process, it is important to consider the feasibility of implementi...Read more -

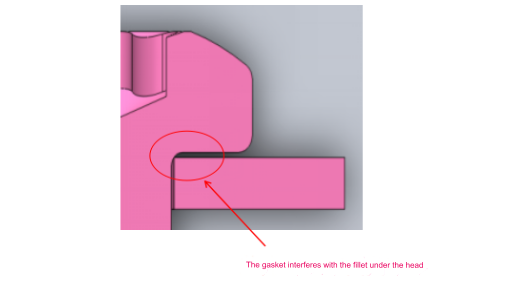

Understand the details of size control in mechanical design | Combination of pictures and text

In mechanical design, controlling the dimensions of a product is a reflection of the designer’s ability. If you lack the necessary design skills, achieving size control can be difficult. Therefore, I would like to share with you some basic design processes and methods that can help you impr...Read more -

When tightening bolts and nuts, should you use flat washers or spring washers?

Many people want to save flat washers or spring washers in order to save costs. In fact, flat washers and spring washers each play an indispensable role in the use of bolts. Today we will introduce to you flat pads and spring pads. Left flat pad, right spring pad A flat washer is a...Read more -

The importance of hand-scraped bed for precision machine tools

Why do precision machine tools have to be scraped by hand? Scraping is a highly challenging technique that surpasses wood carving in complexity. It serves as the fundamental basis for precision tool functions by ensuring accurate surface finishing. Scraping eliminates our reliance on other machin...Read more -

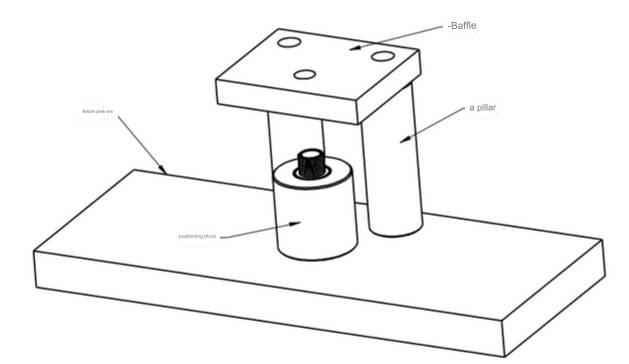

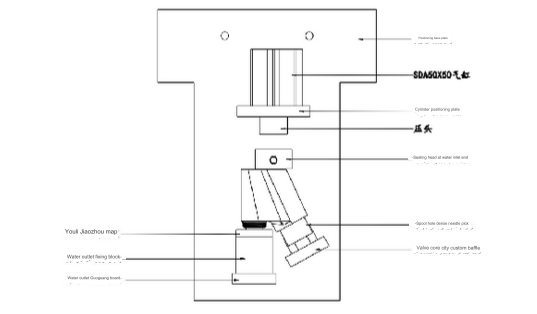

Keep in mind the design points of special tooling fixtures | Ensure maximum processing stability and accuracy

The development of tooling fixtures usually takes place in accordance with the particular needs of a given process, once the parts’ machining process has been established. It is important to fully consider the feasibility of implementing the fixtures while formulating the process. When crea...Read more -

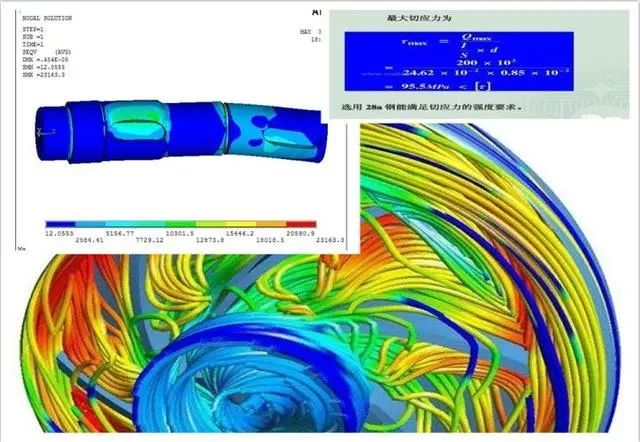

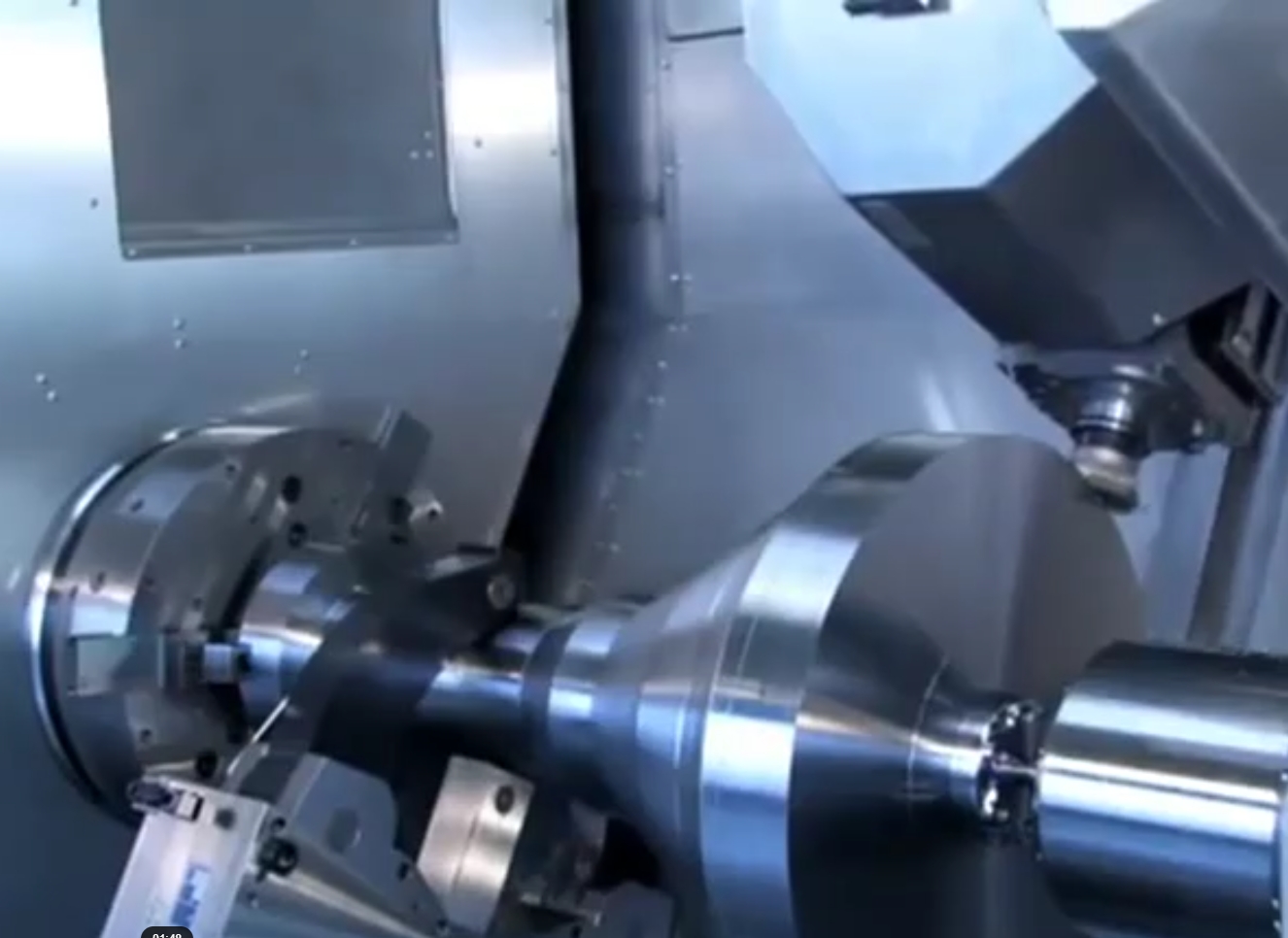

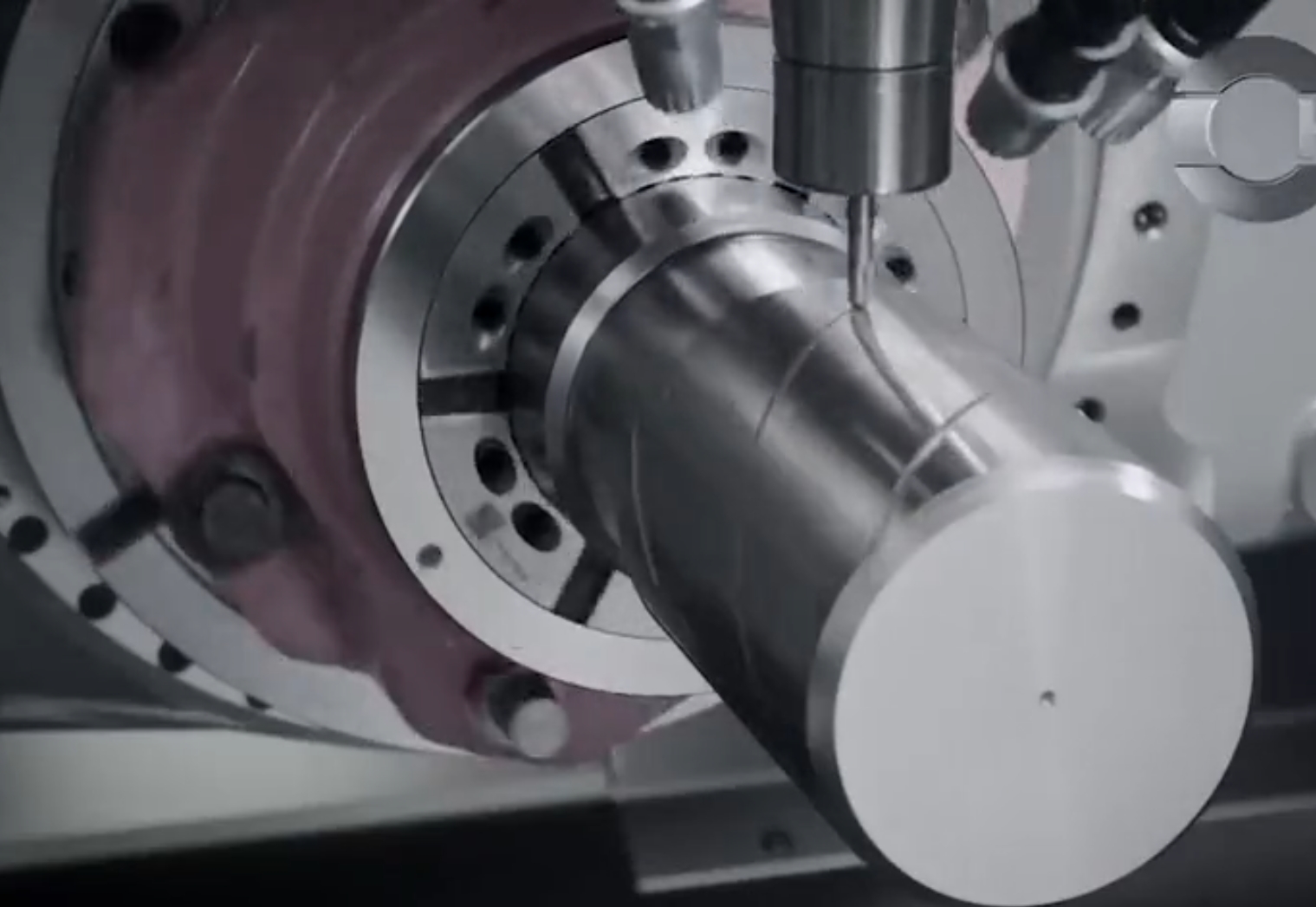

Mastering the Lathe: Eight Essential Techniques Revealed

1. Cleverly obtain tiny amounts of food and use trigonometric functions cleverly Acquire small amounts of food with ingenuity and apply trigonometric functions effectively.During the turning process, workpieces with inner and outer circles requiring high accuracy are frequently processed. ...Read more -

Cutting-edge Methods and Skillful Applications to Prevent Aluminum Part Deformation

Numerous factors contribute to the distortion of aluminum components during the manufacturing process, including material properties, part geometry, and production parameters. The primary factors encompass internal stress within the raw material, distortion resulting from machining forces and he...Read more -

Critical Requisites for Machinery Blueprints

The Technical Requirements for mechanical drawings compiled by the Anebon team covers the following basic requirements directory: 1. General technical requirements 2. Heat treatment requirement 3. Tolerance requirement 4. Part Angle 5. Assembly requirement 6. Casting requirement 7. Coating requir...Read more -

Comprehensive Guide to Stainless Steel

Stainless steel is a popular choice for making instruments. Learning about stainless steel can help instrument users become more adept at selecting and using instruments effectively. Stainless steel, often abbreviated as SS, is able to withstand exposure to air, steam, water, and other mil...Read more -

From Entry-Level to Expert: Unpacking the Skills Expected of Mechanical Designers

What are the basic abilities that a qualified mechanical designer should possess? To be a good mechanical designer, you need to have a bunch of skills, like: 1. Being really good at using CAD software and other design tools 2. Knowing a lot about engineering principles 3. Being able to make re...Read more -

The art of boosting machine tool accuracy with backlash and pitch compensation

The efficiency of CNC machine tool equipment is closely tied to its accuracy, making it a key priority for companies when procuring or developing such tools. However, the accuracy of most new machine tools often falls short of the required standards upon leaving the factory. Additionally, the occ...Read more -

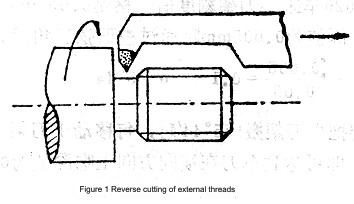

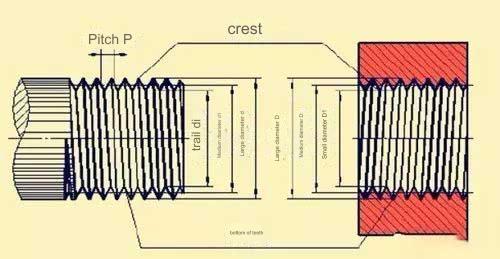

Reasonable induction and derived knowledge of thread standards

How much do you know about machined threads? In the realm of machining, “threads” typically refer to the helical ridges and valleys on the surface of a cylindrical part, which enable it to be connected with another part or be used to transmit motion or power. The definitions and...Read more