Indispensable Fixtures for CNC Machining — Soft Jaws

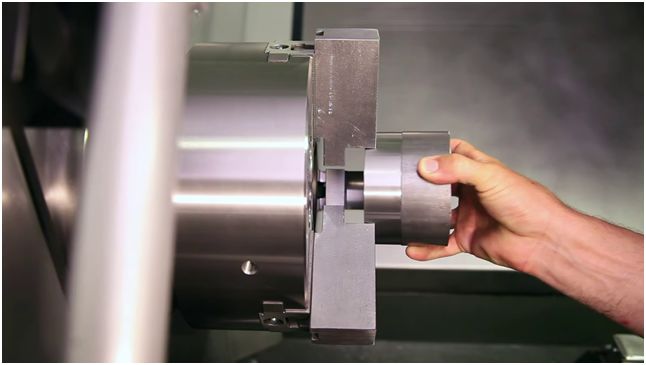

The soft claw can ensure the repeated positioning accuracy of the workpiece to the greatest extent, so that the centerline of the processed workpiece can completely coincide with the centerline of the spindle, and the flat surface on the soft claw can also ensure the length of the workpiece.

What’s more important:

The soft claw can fit the surface of the workpiece to the greatest extent, which can not only ensure the transmission of greater torque, but also avoid the workpiece from being pinched. These advantages are incomparable to the hard claw.

When making soft claws, you need to pay attention to the following issues:

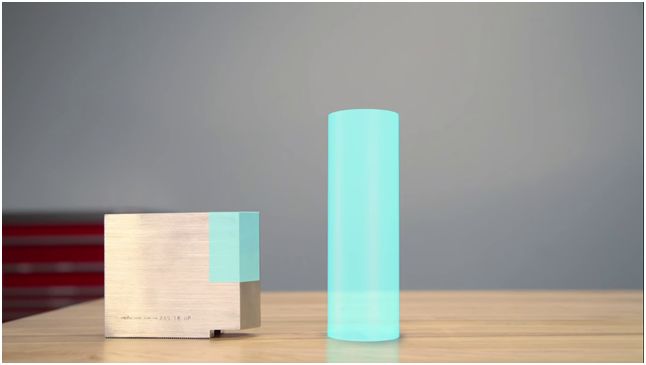

1. Selection of soft claw material

“Soft” here means: good processing performance does not mean that it must be lower than the hardness of the workpiece. (For mass production, the hardness of the soft jaws will have a great impact on the stability of processing. Choosing a soft jaw material with a higher hardness than the workpiece will not only improve the service life of the soft jaws, but also affect the stability of processing. Positive effect)

2. Selection of the size of the soft jaws, the soft jaws should hold at least 1/3 of the length of the cnc part.

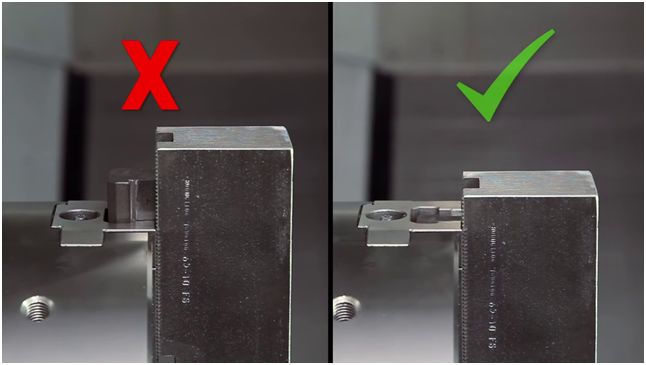

3. For the installation position of the soft jaw on the chuck, any T-shaped block exceeding the maximum diameter of the chuck is not allowed, which will pose a great safety risk.

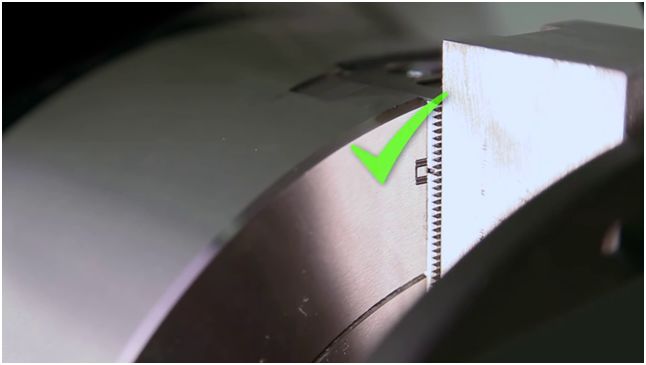

4. Pressure and position when using the claw trimmer

It is recommended that the pressure during use is close to the pressure during workpiece processing. The chuck is in the middle of the range of motion during processing, and the direction of the clamping force when repairing the jaws is consistent with the direction of the CNC turned parts clamping force.

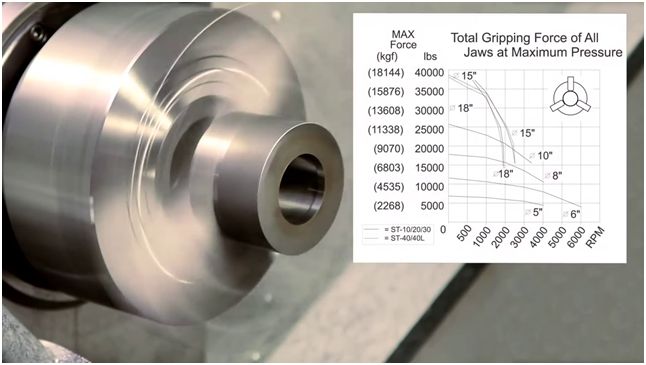

5. The influence of chuck diameter and rotational speed on clamping force

Due to the effect of centrifugal force, when the chuck operates at high speed, the clamping force will be greatly reduced. For details, please refer to the instructions on the chuck.

6. Make an inner hole of the same size as the diameter of the cnc milling part to reduce the possibility of pinching the workpiece.

7. Add an undercut

To ensure repeated positioning of the workpiece

8. Remove burrs and sharp corners on the soft claws

Be careful not to scratch your hands

Anebon‘s eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” and the theory of “quality the basic, trust the first and management the advanced” for Hot sale Factory OEM Service High Precision CNC Machining parts for automation industrial, Anebon quote for your inquiry. For more information, please get in touch with us, Anebon will reply you ASAP!

Hot sale Factory China 5 axis cnc machining parts, CNC turned parts and milling copper part. Welcome to visit our company, factory and our showroom where displays various hair merchandise that will meet your expectation. Meanwhile, it is convenient to visit Anebon’s website, and Anebon sales staff will try their best to deliver you the best service. Please contact Anebon if you have to have more information. Aim of Anebon is to help customers realize their goals. Anebon have been making great efforts to achieve this win-win situation.

Post time: Mar-17-2023