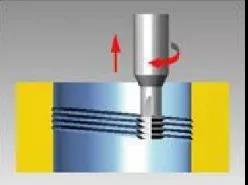

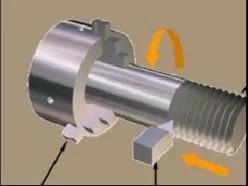

Common thread cutting methods

Milling Thread Turning Thread

Technological process

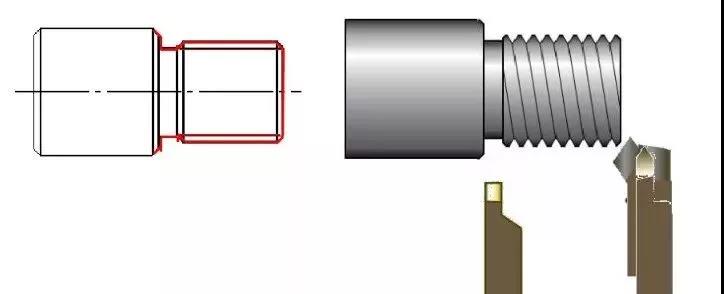

Turning end face one turning thread major diameter (d < nominal diameter) one turning undercut (< thread minor diameter) → chamfering → turning thread (multi cutter turning)

Installation skills

Installation of workpiece

Select the proper clamping position.

There is enough clamping force.

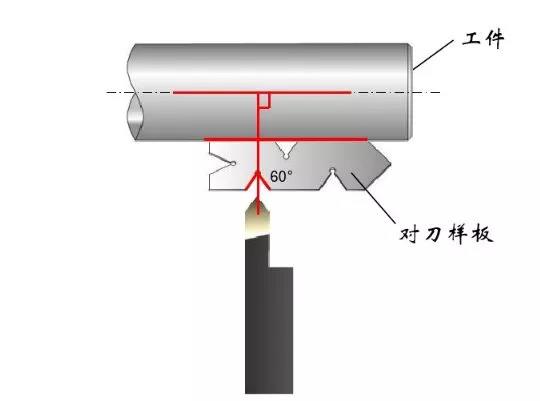

Mount the installment

Key points of installation: the angle dividing line of the tool tip is perpendicular to the axis of the workpiece. cnc turning part

Machine tool adjustment

For thread turning

Adjust the spindle speed

Adjusting pitch

Notice

1. Avoid "random buckle"

[if the latter knife fails to fall into the thread groove of the turning method of the former knife, the workpiece will be scrapped. ]

If the screw pitch is not the integral value of the workpiece pitch, it must be turned by turning forward and backward

The relative position between the workpiece and the spindle cannot be changed.

If the tool is changed or grinded, the tool should be adjusted again. cnc machining part

2. Prevent "stabbing"

[the distribution of machining allowance is unreasonable, or the allowance of one turning is more reasonable, which makes the two sides of the thread rough and even chipped. ]

Workpiece and tool clamping

Reasonable allocation of allowance and selection of proper feed method

Withdraw the knife in time.

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Post time: Jan-02-2020