The fixture design is generally carried out in accordance with the specific requirements of a certain process after the machining process of the parts is formulated. In formulating the technological process, the possibility of fixture realization should be fully considered, and when designing the fixture, it is possible to propose amendments to the technological process if necessary. The design quality of tooling fixtures should be measured by whether it can stably guarantee the processing quality of the workpiece, high production efficiency, low cost, convenient chip removal, safe operation, labor-saving, easy manufacturing, and easy maintenance.

1. The basic principles of fixture design

1. Satisfy the stability and reliability of workpiece positioning during use;

2. There is sufficient load bearing or clamping force to ensure the processing of the workpiece on the fixture;

3. Satisfy simple and fast operation in the clamping process;

4. The fragile parts must be of a structure that can be replaced quickly, and it is best not to use other tools when the conditions are sufficient;

5. Satisfy the reliability of repeated positioning of the fixture during adjustment or replacement;

6. Avoid complex structure and high cost as much as possible;

7. Choose standard parts as component parts as much as possible;

8. Form the systemization and standardization of the company's internal products.

2. Basic knowledge of fixture design

A good machine tool fixture must meet the following basic requirements:

1. Ensure the machining accuracy of the workpiece. The key to ensuring the machining accuracy is to correctly select the positioning datum, positioning method and positioning components. If necessary, positioning error analysis is also required. Also pay attention to the structure of other parts in the fixture to the machining accuracy The influence of this to ensure that the fixture can meet the machining accuracy requirements of the workpiece.

2. The complexity of the special fixture for improving production efficiency should be adapted to the production capacity. Various fast and efficient clamping mechanisms should be adopted as far as possible to ensure convenient operation, shorten auxiliary time, and improve production efficiency.

3. The structure of the special fixture with good process performance should be simple and reasonable, which is convenient for manufacturing, assembly, adjustment, inspection, maintenance, etc.

4. Good use performance. The fixture should have sufficient strength and rigidity, and the operation should be simple, labor-saving, safe and reliable. Under the premise that objective conditions permit and are economical and applicable, pneumatic, hydraulic and other mechanized clamping devices should be used as much as possible to reduce the labor intensity of the operator. Tooling fixtures should also be convenient for chip removal. When necessary, a chip removal structure can be set to prevent chips from damaging the positioning of the workpiece and damaging the tool, and preventing the accumulation of chips from bringing a lot of heat and causing deformation of the process system.

5. The special fixture with good economy should adopt standard components and standard structure as much as possible, and strive to be simple in structure and easy to manufacture, so as to reduce the manufacturing cost of the fixture. Therefore, the necessary technical and economic analysis of the fixture plan should be carried out according to the order and production capacity during the design to improve the economic efficiency of the fixture in the production. aluminum part

3. Overview of the standardization of tooling and fixture design

1. Basic methods and steps of fixture design

Preparation before design. The original data of tooling and fixture design includes the following:

a) Design notices, finished parts drawings, blank drawings and process routes and other technical materials, understand the processing technical requirements of each process, positioning and clamping schemes, the processing content of the previous process, the status of the blanks, the machine tools and tools used in the processing , Inspection of measuring tools, machining allowance and cutting amount, etc.;

b) Understand the production batch and the demand for fixtures;

c) Understand the main technical parameters, performance, specifications, accuracy of the machine tool used, and the connection size of the structure of the connection part with the fixture, etc.;

d) Standard material inventory of fixtures. cnc machining metal part

2. Issues considered in the design of fixtures

The fixture design generally has a single structure, which gives people the feeling that the structure is not very complicated, especially now that the popularity of hydraulic fixtures greatly simplifies the original mechanical structure, but if the design process is not considered in detail, unnecessary troubles will inevitably occur:

a) The blank margin of the workpiece. The size of the blank is too large and interference occurs. Therefore, the rough drawing must be prepared before designing. Leave enough space.

b) Unblocked chip removal of the fixture. Due to the limited processing space of the machine tool during the design, the fixture is often designed to be compact. At this time, it is often ignored that the iron filings generated during the processing process are stored in the dead corners of the fixture, including the poor flow of the chip liquid, which will cause future Processing brings a lot of trouble. Therefore, at the beginning of the actual situation, we should consider the problems in the processing process. After all, the fixture is based on improving efficiency and convenient operation.

c) The overall openness of the fixture. Ignoring the openness makes it difficult for the operator to install the card, time-consuming and laborious, and design taboos.

d) The basic theoretical principles of fixture design. Each fixture has to undergo countless clamping and loosening actions, so it may be able to meet the user's requirements at the beginning, but the fixture should have its accuracy retention, so don't design something that is contrary to the principle. Even if you are lucky now, there will be no long-term sustainability. A good design should stand the temper of time.

e) Replaceability of positioning components. The positioning components are severely worn, so quick and convenient replacement should be considered. It is best not to design into larger parts.

Accumulation of fixture design experience is very important. Sometimes design is one thing, but it is another thing in practical application, so good design is a process of continuous accumulation and summarization.

Commonly used fixtures are mainly divided into the following types according to their functionality:

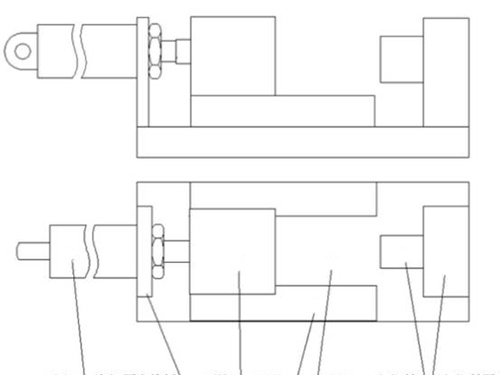

01 clamp

02Drilling and milling tooling

03CNC, instrument chuck

04 Gas and water test tooling

05 Trimming and punching tooling

06 welding tooling

07 Polishing fixture

08 Assembly tooling

09 Pad printing, laser engraving tooling

Anebon Metal Products Limited can provide CNC Machining、Die Casting、Sheet Metal Fabrication service, please feel free to contact us.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post time: Mar-29-2021