Compared with metal, plastic can generally increase the feed rate and reduce the wear of the machine and the cutting head. However, certain plastics are still difficult to process. When you remove the material, it may melt, chip, or go out of tolerance.

Acetal, polyetheretherketone, and polyvinyl chloride plastic materials have excellent mechanical processing characteristics and provide good dimensional stability while resisting melting and chipping.

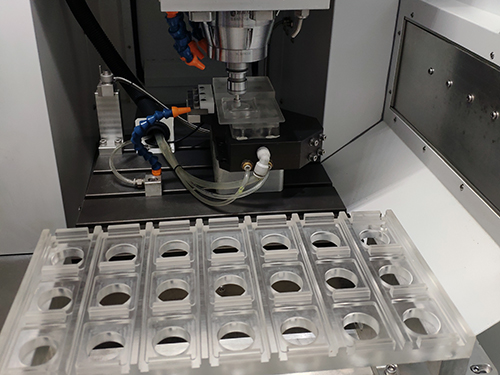

CNC Mills- These machines are usually used to create a flat part. It works by holding the plastic material stationary while the spindle rotates with the tools along three axes to form the shape it was programmed to make.

CNC Lathes- You should use a CNC lathe when making a plastic cylindrical part. This allows you to create curved surfaces you would never be able to make on a manual lathe.

These machines work by spinning the material in the chunk of the lathe while a tool is moved in two axes to create your desired shape.

CNC Grinders- Typically used to create high-quality surface fish, CNC grinders work by moving a grinding wheel into the plastic. It's worth noting that you should only use these machines for hardened plastic.

CNC Drills- Similar to CNC mills, the only difference between these two machines is that drills are designed to cut along one axis only. Namely, the drill moves down the Z-axis.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website: www.anebon.com

Post time: Nov-04-2020