I have been doing machinery for so many years, and have processed various machining parts, turning parts and milling parts through CNC machine tools and precision equipment. There is always one part that is essential, and that is the screw.

The performance grades of bolts for steel structure connection are divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, among which the bolts of grade 8.8 and above are made of low-carbon alloy steel or medium-carbon steel and have been heat-treated (quenching, tempering), commonly known as high-strength bolts, and the rest are commonly referred to as ordinary bolts. The bolt performance grade label consists of two parts of numbers, which respectively represent the nominal tensile strength value and yield strength ratio of the bolt material. For example:

The meaning of bolts with performance level 4.6 is:

The nominal tensile strength of the bolt material reaches 400MPa;

The yield ratio of the bolt material is 0.6;

The nominal yield strength of the bolt material reaches 400×0.6=240MPa level.

Performance grade 10.9 high-strength bolts, after heat treatment, can reach:

The nominal tensile strength of the bolt material reaches 1000MPa;

The yield ratio of the bolt material is 0.9;

The nominal yield strength of the bolt material reaches 1000×0.9=900MPa level.

The meaning of bolt performance grade is an international standard. Bolts of the same performance grade have the same performance regardless of the difference in their materials and origins. Only the performance grade can be selected for design.

The so-called 8.8 and 10.9 strength grades mean that the shear stress grades of the bolts are 8.8GPa and 10.9GPa

8.8 Nominal tensile strength 800N/MM2 Nominal yield strength 640N/MM2

General bolts use “X.Y” to indicate strength, X*100=tensile strength of this bolt, X*100*(Y/10)=yield strength of this bolt (because according to the label: yield strength/tensile strength =Y/10)

Such as grade 4.8, the tensile strength of this bolt is: 400MPa; the yield strength is: 400*8/10=320MPa.

Another: stainless steel bolts are usually marked as A4-70, A2-70, the meaning is explained otherwise.

measure

There are mainly two kinds of length measurement units in the world today, one is the metric system, and the measurement units are meters (m), centimeters (cm), millimeters (mm), etc., which are widely used in Southeast Asia such as Europe, my country, and Japan, and the other is the metric system. The type is the imperial system, and the unit of measurement is mainly inches, which is equivalent to the old system in my country, and is widely used in the United States, the United Kingdom and other European and American countries.

Metric measurement: (decimal system) 1m = 100 cm = 1000 mm

Inch measurement: (octal system) 1 inch = 8 inches 1 inch = 25.4 mm 3/8 × 25.4 = 9.52

1/4 of the following products use numbers to represent their appellation diameters, such as: 4#, 5#, 6#, 7#, 8#, 10#, 12#

thread

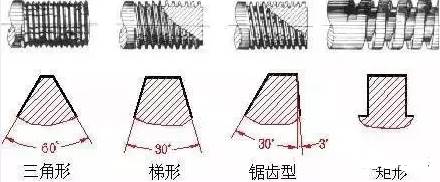

A thread is a shape with uniform helical projections on a section of a solid external or internal surface. According to its structural characteristics and uses, it can be divided into three categories:

Ordinary thread: The tooth shape is triangular, used to connect or fasten parts. Ordinary threads are divided into coarse and fine threads according to the pitch, and the connection strength of fine threads is higher.

Transmission thread: The tooth shape includes trapezoidal, rectangular, saw-shaped and triangular.

Sealing thread: used for sealing connection, mainly pipe thread, tapered thread and tapered pipe thread.

Classified by shape:

Thread fit grade

Thread fit is the degree of looseness or tightness between screwed threads, and the degree of fit is the prescribed combination of deviations and tolerances acting on internal and external threads.

1. For unified inch threads, there are three thread grades for external threads: 1A, 2A and 3A, and three grades for internal threads: 1B, 2B and 3B, all of which are clearance fits. The higher the grade number, the tighter the fit. In the inch thread, the deviation only stipulates grades 1A and 2A, the deviation of grade 3A is zero, and the grade deviation of grade 1A and grade 2A is equal. The larger the number of grades, the smaller the tolerance.

Classes 1A and 1B, very loose tolerance classes, which are suitable for tolerance fits of internal and external threads.

Classes 2A and 2B are the most common thread tolerance classes specified for imperial series mechanical fasteners.

Class 3A and 3B, screwed to form the tightest fit, suitable for fasteners with tight tolerances, and used in safety-critical designs.

For external threads, grades 1A and 2A have a fit tolerance, grade 3A does not. Class 1A tolerances are 50% larger than Class 2A tolerances, 75% larger than Class 3A tolerances, and Class 2B tolerances are 30% larger than Class 2A tolerances for internal threads. Class 1B is 50% larger than Class 2B and 75% larger than Class 3B.

2. For metric threads, there are three thread grades for external threads: 4h, 6h and 6g, and three thread grades for internal threads: 5H, 6H, and 7H. (The Japanese standard thread accuracy grade is divided into three grades: I, II, and III, and it is usually grade II.) In the metric thread, the basic deviation of H and h is zero. The basic deviation of G is positive, and the basic deviation of e, f and g is negative.

H is the commonly used tolerance zone position for internal threads, and is generally not used as a surface coating, or a very thin phosphating layer is used. The basic deviation of the G position is used for special occasions, such as thicker coatings, and is generally rarely used.

g is often used to plate a thin coating of 6-9um. If the product drawing requires a bolt of 6h, the thread before plating adopts a tolerance zone of 6g.

The thread fit is best combined into H/g, H/h or G/h. For the threads of refined fasteners such as bolts and nuts, the standard recommends a fit of 6H/6g.

3. Thread marking

Main geometric parameters of self-tapping and self-drilling threads

1. Major diameter/tooth outer diameter (d1): It is the diameter of an imaginary cylinder where the thread crests coincide. The thread major diameter basically represents the nominal diameter of the thread size.

2. Minor diameter/root diameter (d2): It is the diameter of the imaginary cylinder where the thread bottom coincides.

3. Tooth distance (p): It is the axial distance between adjacent teeth corresponding to two points on the mid-meridian. In the imperial system, the tooth distance is indicated by the number of teeth per inch (25.4mm).

The following is a list of common specifications of tooth pitch (metric system) and number of teeth (imperial system)

1) Metric self-tapping teeth:

Specifications: S T1.5, S T1.9, S T2.2, S T2.6, S T2.9, S T3.3, S T3.5, S T3.9, S T4.2, S T4.8, S T5.5, S T6.3, S T8.0, S T9.5

Pitch: 0.5, 0.6, 0.8, 0.9, 1.1, 1.3, 1.3, 1.3, 1.4, 1.6, 1.8, 1.8, 2.1, 2.1

2) Imperial self-tapping teeth:

Specifications: 4#, 5#, 6#, 7#, 8#, 10#, 12#, 14#

Number of teeth: AB teeth 24, 20, 20, 19, 18, 16, 14, 14

A teeth 24, 20, 18, 16, 15, 12, 11, 10

Post time: Feb-02-2023