It is frustrating to give up the contract due to insufficient processing capacity in your mechanical workshop or for some reason. To keep these contracts and establish business, some factory owners outsource processing work. Here are some of the benefits you will get when outsourcing CNC machining.

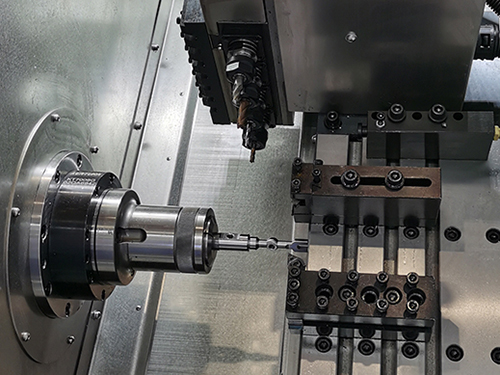

1. With the help of contract manufacturing, we can hire and use experienced personnel and sophisticated CNC equipment indirectly. To reduce investment costs.

2. You can free up your own factory's labor and machines to do more projects

3. Quality and delivery are also controlled. Because when the supplier completes the production, they will conduct quality inspections. When the product arrives at its factory, it must also be tested. After two inspections, I believe the product's quality will not be a problem.

4. If you encounter large quantities of regular purchase orders. Outsourcing processing will reflect more significant advantages. Generally speaking, the best CNC machining products are the more stable the precision. Therefore, most unions produce two orders in advance after delivering the first order. The remaining quantity will be used as inventory and placed in the supplier's warehouse. And this happens to save space in your warehouse.

If you'd like to speak to a member of the Anebon team for CNC Machining Brass, Machining Cost Estimation, please get in touch at info@anebon.com

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website: www.anebon.com

Post time: Nov-26-2020