Why do precision machine tools have to be scraped by hand?

Scraping is a highly challenging technique that surpasses wood carving in complexity. It serves as the fundamental basis for precision tool functions by ensuring accurate surface finishing. Scraping eliminates our reliance on other machine tools and can effectively remove deviations caused by clamping force and heat energy.

Rails that have been scraped are less susceptible to wear, primarily due to their superior lubrication effect. A scraping technician must be well-versed in a variety of techniques, but their expertise can only be honed through hands-on experience, enabling them to achieve the precise and smooth feel that is required.

Scraping is an intricate and challenging technique that involves the removal of metal from a surface. It is a fundamental process used in precision tool functions, ensuring accurate surface finishing. Scraping eliminates the need for other machine tools and can efficiently remove deviations caused by clamping force and heat energy.

Rails that have undergone scraping exhibit improved lubrication properties, resulting in reduced wear and tear. Becoming a proficient scraping technician requires a deep understanding of various techniques, which can only be honed through hands-on experience. It enables them to achieve the precise and smooth feel required for optimal performance. When you pass by a machine tool manufacturing factory and see the technicians scraping and grinding by hand, you can’t help but wonder: “Can they really improve the current machine-processed surfaces by scraping and grinding?” (People will Is it more powerful than a machine?)”

If you are referring purely to its appearance, then our answer is “no”, we won’t make it more beautiful, but why scratch it? There are reasons for it, of course, and one of them is the human factor: the purpose of a machine tool is to make other machine tools, but it can never replicate a product more accurately than the original. Therefore, if we want to make a machine that is more accurate than the original machine, we must have a new starting point, that is to say, we must start with human efforts. In this case, human efforts refer to scraping and grinding by hand.

Scraping and grinding is not a “freehand” or “freehand” operation. It is actually a copying method that almost perfectly replicates the matrix. This matrix is a standard plane and is also made by hand.

Although scraping and grinding is hard and laborious, it is a skill (an art-level technique); it may be more difficult to train a scraping and grinding master than to train a wood carving master. There are not many books on the market that discuss this topic. In particular, there is less information discussing “why scraping is necessary”. This may be why scraping is considered an art.

In the manufacturing process, it is crucial to maintain accuracy in the surfaces being produced. The method employed in achieving this accuracy is critical, as it directly affects the quality of the final product. For instance, if a manufacturer chooses to grind with a grinder instead of scraping, the rails on the “parent” grinder must be more precise than those on a new grinder.

The question then arises, where did the accuracy of the first machines come from? It must have come from a more accurate machine or relied on some other method of producing a truly flat surface or perhaps copied from an already well-done flat surface.

To illustrate the concept of surface creation, we can use three methods of drawing circles. Although circles are lines and not surfaces, they can help explain the idea. A skilled craftsman can draw a perfect circle with an ordinary compass. However, if they trace a pencil along a hole in a plastic template, they will replicate all the inaccuracies in the hole. If they attempt to draw it freehand, the accuracy of the circle depends on their limited skills.

If a manufacturer decides to grind with a grinder instead of scraping, the rails on his “parent” grinder must be more accurate than on a new grinder.

So where did the accuracy of the first machines come from?

It must have come from a more accurate machine or relied on some other method of producing a truly flat surface or perhaps copied from an already well-done flat surface.

We can use three methods of drawing circles to illustrate the creation process of surfaces (although circles are lines and not surfaces, they can be quoted to illustrate the concept). A craftsman can draw a perfect circle with an ordinary compass; if he traces a pencil along a hole in a plastic template, he will replicate all the inaccuracies in the hole; if he draws it freehand, As for the circle, the accuracy of the circle depends on his limited skills.

In theory, a perfectly flat surface can be produced by alternating friction (lapping) of three surfaces. For the sake of simplicity, let’s illustrate with three rocks, each with a fairly flat surface. If you rub these three surfaces alternately in random order, you will grind the three surfaces smoother and smoother. If you rub just two rocks together, you’ll end up with a mating pair of one bump and one bump. In practice, in addition to using scraping instead of lapping (Lapping), a clear pairing sequence will also be followed. Scraping masters generally use this rule to make the standard jig (straight gauge or flat plate) that they want to use.

When using it, the scraper master will first apply the color developer on the standard jig, and then slide it on the surface of the workpiece to reveal the areas that need to be scraped off. He keeps repeating this action, and the surface of the workpiece will get closer and closer to the standard jig, and finally, he can perfectly copy the work that is the same as the standard jig.

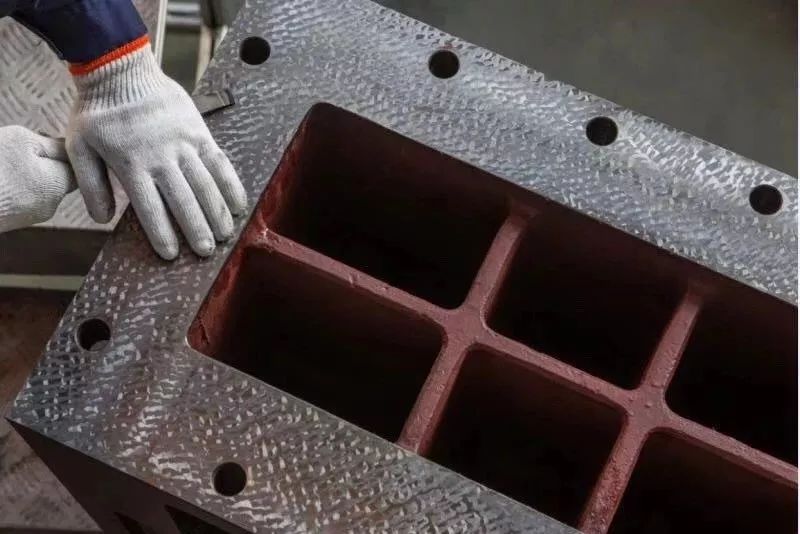

Castings that require finishing are generally milled to be slightly larger than the final size, and then sent for heat treatment to release residual pressure. Subsequently, the castings are subjected to surface finishing grinding before undergoing scraping. While the scraping process demands a significant amount of time, labor, and cost, it can replace the need for high-end equipment, which comes with a hefty price tag. If scraping is not used, the workpiece must be finished using an expensive, high-precision machine, or go through costly repair processing.

In the process of finishing parts, specifically large castings, the use of gravity clamping actions is often necessary. The clamping force, when the processing reaches a few thousandths of high precision, can, however, cause distortion of the workpiece, endangering the accuracy of the workpiece after releasing the clamping force. Additionally, the heat generated during processing can also cause distortion of the workpiece. Scraping, with its advantages, comes in handy in such scenarios. There is no clamping force, and the heat generated by scraping is almost negligible. Large workpieces are supported at three points to guarantee that they do not deform due to their weight.

When the scraping track of the machine tool becomes worn, it can be re-corrected by scraping. This is a significant advantage compared to the alternative of discarding the machine or sending it to the factory for disassembly and reprocessing. The factory’s maintenance personnel or local experts can perform the scraping and grinding work.

In some cases, manual scraping and power scraping can be utilized to achieve the final required geometric accuracy. A skilled scraping master can complete this type of correction in a surprisingly short time. Although this method requires skilled technology, it is more cost-effective than processing a large number of parts to be highly accurate, or making some reliable or adjustable designs to prevent alignment errors. However, it is important to note that this solution should not be used as an approach to correct significant alignment errors, as it was not its original purpose.

Improvement of lubrication

In the manufacturing process of castings, finishing requires milling the castings to slightly larger than their final size, followed by heat treatment to release residual pressure. Castings are then subjected to surface finishing grinding and scraping. Although the scraping process is time-consuming and expensive, it can replace the need for high-end equipment that comes with a hefty price tag. Without scraping, finishing the workpiece requires an expensive, high-precision machine or costly repair processing.

Gravity clamping actions are often required when finishing parts, especially large castings. However, clamping force can cause distortion of the workpiece, endangering accuracy after releasing the clamping force. Scraping comes in handy in such scenarios, as there is no clamping force, and the heat generated by scraping is almost negligible. Large workpieces are supported at three points to prevent deformation due to their weight.

When the scraping track of the machine tool becomes worn, it can be re-corrected by scraping, which is more cost-effective than discarding the machine or sending it to the factory for disassembly and reprocessing. Manual and power scraping can be utilized to achieve the final required geometric accuracy. Although this method requires skilled technology, it is more cost-effective than processing a large number of machining parts to be highly accurate or making reliable or adjustable designs to prevent alignment errors. However, it is important to note that this solution should not be used to correct significant alignment errors, as it was not its original purpose. Improvement of lubrication

Practical experience has proven that scraping rails can reduce friction through better quality lubrication, but there is no consensus as to why. The most common opinion is that scraped low spots (or more specifically, gouged dimples, extra oil pockets for lubrication) provide many tiny pockets of oil, which are absorbed by the many tiny surrounding high spots. Scrape it out.

Another way to put it logically is that it allows us to continuously maintain a film of oil on which the moving parts float, which is the goal of all lubrication. The main reason why this happens is that these irregular oil pockets form a lot of space for oil to stay, making it difficult for the oil to escape easily. The ideal situation for lubrication is to maintain a film of oil between two perfectly smooth surfaces, but then you have to deal with preventing the oil from escaping, or needing to replenish it as quickly as possible. (Whether there is scraping on the track surface or not, oil grooves are usually made to help the distribution of oil).

Such a statement would make people question the effect of contact area. Scratching reduces the contact area but creates an even distribution, and distribution is the important thing. The flatter the two matching surfaces, the more evenly distributed the contact areas will be. But there is a principle in mechanics that “friction has nothing to do with area.” This sentence means that whether the contact area is 10 or 100 square inches, the same force is required to move the workbench. (Wear is another matter. The smaller the area under the same load, the faster the wear.)

The point I want to make is that what we are looking for is better lubrication, not more or less contact area. If the lubrication is flawless, the track surface will never wear out. If a table has difficulty moving as it wears out, this may be related to the lubrication, not the area of contact.

How is scraping done?

Before finding the high points that must be scraped off, first apply the color developer on the standard jig (flat plate or straight jig when scraping V-shaped rails), and then put the color developer on the standard jig. By rubbing on the track surface to be shoveled, the color developer will be transferred to the high points of the track surface, and then a special scraping tool is used to remove the high points of the color development. This action should be repeated until the track surface shows a uniform transfer.

Of course, a scraping master must know various techniques. Let me talk about two of them here:

In the manufacturing process of castings, finishing requires milling the castings slightly larger than their final size, followed by heat treatment to release residual pressure. The castings are then subjected to surface finishing grinding and scraping. Although the scraping process is time-consuming and expensive, it can replace the need for high-end equipment that comes with a hefty price tag. Without scraping, finishing the workpiece requires an expensive, high-precision machine or costly repair processing.

When finishing parts, especially large castings, gravity clamping actions are often required. However, clamping force can cause distortion of the workpiece, endangering accuracy after releasing the clamping force. Scraping comes in handy in such scenarios, as there is no clamping force, and the heat generated by scraping is almost negligible. Large workpieces are supported at three points to prevent deformation due to their weight.

When the scraping track of the machine tool becomes worn, it can be re-corrected by scraping, which is more cost-effective than discarding the machine or sending it to the factory for disassembly and reprocessing. Manual and power scraping can be utilized to achieve the final required geometric accuracy. Although this method requires skilled technology, it is more cost-effective than processing a large number of cnc parts to be highly accurate or making reliable or adjustable designs to prevent alignment errors. However, it is important to note that this solution should not be used to correct significant alignment errors, as it was not its original purpose.

Practical experience has proven that scraping rails can reduce friction through better quality lubrication, but there is no consensus as to why. The most common opinion is that scraped low spots (or more specifically, gouged dimples, extra oil pockets for lubrication) provide many tiny pockets of oil, which are absorbed by the many tiny surrounding high spots. Scratching reduces the contact area but creates an even distribution, and distribution is the important thing. The flatter the two matching surfaces, the more evenly distributed the contact areas will be. But there is a principle in mechanics that “friction has nothing to do with area.” This sentence means that whether the contact area is 10 or 100 square inches, the same force is required to move the workbench. (Wear is another matter. The smaller the area under the same load, the faster the wear.)

The point is that what we are looking for is better lubrication, not more or less contact area. If the lubrication is flawless, the track surface will never wear out. If a table has difficulty moving as it wears out, this may be related to the lubrication, not the area of contact.First, before we do the color development, we usually use a dull file to gently rub on the surface of the workpiece to remove the burrs.

Second, wipe the surface with a brush or your hands, never with a rag. If you use a cloth to wipe, the fine lines left by the cloth will cause misleading marks the next time you do high-point color development.

The scraping master himself will check his work by comparing the standard jig with the track surface. The inspector only needs to tell the scraping master when to stop the work, and there is no need to worry about the scraping process. (The scraping master can be responsible for the quality of his own work)

We used to have a set of standards that dictated how many high spots there should be per square inch, and what percentage of the total area should be in contact; but we found that checking the contact area was almost impossible, and now it’s all done by scraping The master grinder determines the number of dots per square inch. In short, scraping masters generally strive to achieve a standard of 20 to 30 dots per square inch.

In the current scraping process, electric scraping machines are used for some leveling operations. They are also a type of manual scraping, but they can eliminate some strenuous work and make the scraping work less tiring. There’s still no substitute for the feeling of hand scraping when you’re doing the most delicate assembly work.

Anebon depends on sturdy technical force and continually creates sophisticated technologies to meet the demand for CNC metal machining, 5-axis CNC milling, and casting automobiles. All the opinions and suggestions will be greatly appreciated! The good cooperation could improve both of us into better development!

ODM Manufacturer China Customized aluminum milling Parts and machinery parts making, At present, Anebon’s items have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada, etc. Anebon sincerely hopes to establish wide contact with all potential customers both in China and the rest part of the world.

Post time: Mar-05-2024