What is a bearing?

Bearings are parts that support the shaft, used to guide the rotational movement of the shaft, and bear the load transmitted from the shaft to the frame. Bearings are widely used and demanding supporting parts and basic parts in the machinery industry. They are the supporting components of the rotating shafts or movable parts of various machines, and are also the supporting components that rely on the rolling of rolling bodies to realize the rotation of the main engine. Known as mechanical joints.

How should bearings be classified?

According to the different friction forms when the journal works in the bearing,the bearings are divided into two categories:

sliding bearings and rolling bearings.

-

Plain bearing

According to the direction of the load on the bearing, sliding bearings are divided into three categories:①Radial bearing——to bear radial load, and the load direction is perpendicular to the centerline of the shaft;

②Thrust bearing——to bear axial load, and the load direction is parallel to the center line of the shaft;

③Radial-thrust bearing——simultaneously bears radial and axial loads.

According to the friction state, sliding bearings are divided into two categories: non-fluid friction sliding bearings and liquid friction sliding bearings. The former is in the state of dry friction or boundary friction, and the latter is in the state of liquid friction.

-

rolling bearing

(1) According to the load direction of the rolling bearing, it can be divided into:①The radial bearing mainly bears the radial load.

②Thrust bearing mainly bears axial load.

(2) According to the shape of the rolling elements, it can be divided into: ball bearings and roller bearings. The rolling elements in the bearing have single row and double row.

(3) According to the load direction or nominal contact angle and the type of rolling elements, it can be divided into:

1. Deep groove ball bearings.

2. Cylindrical roller bearings.

3. Needle bearings.

4. Self-aligning ball bearings.

5. Angular contact ball bearings.

6. Spherical roller bearings.

7. Tapered roller bearings.

8. Thrust angular contact ball bearings.

9. Thrust spherical roller bearings.

10. Thrust tapered roller bearings.

11. Thrust ball bearings.

12. Thrust cylindrical roller bearings.

13. Thrust needle roller bearings.

14. Composite bearings.

In rolling bearings, there is point or line contact between the rolling elements and the raceway, and the friction between them is rolling friction. When the speed is high, the life of the rolling bearing drops sharply; when the load is large and the impact is large, the rolling bearing points or lines contact.

In sliding bearings, there is surface contact between the journal and the bearing, and sliding friction between the contact surfaces. The structure of the sliding bearing is that the journal is matched with the bearing bush; the selection principle is to give priority to the selection of rolling bearings, and use sliding bearings in special cases. Sliding bearing surface contact; the special structure requires a super large structure, and the cost of the sliding bearing is low.

-

Bearings are divided into radial bearings and thrust bearings according to the bearing direction or nominal contact angle.

-

According to the type of rolling element, it is divided into: ball bearings, roller bearings.

-

According to whether it can be aligned, it is divided into: self-aligning bearings, non-aligning bearings (rigid bearings).

-

According to the number of rows of rolling elements, it is divided into: single-row bearings, double-row bearings, and multi-row bearings.

-

According to whether the parts can be separated, they are divided into: separable bearings and non-separable bearings.

In addition, there are classifications by structural shape and size.

This article mainly shares the characteristics, differences and corresponding uses of 14 common bearings.

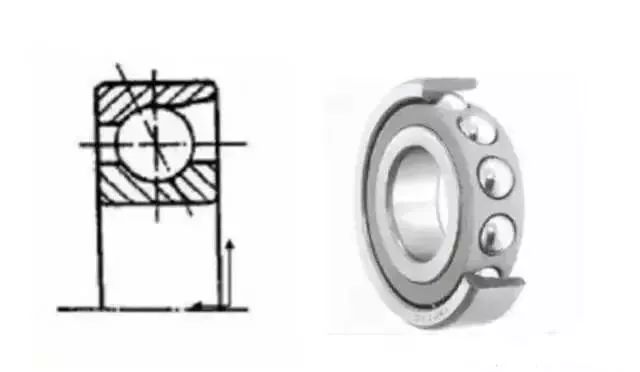

1. Angular contact ball bearings

There is a contact angle between the ferrule and the ball. The standard contact angle is 15°, 30° and 40°. The larger the contact angle is, the greater the axial load capacity is. The smaller the contact angle is, the more favorable it is for high-speed rotation. Single row bearings can Bear radial load and one-way axial load. In structure, two single row angular contact ball bearings combined on the back share the inner ring and outer ring, which can bear radial load and bidirectional axial load.

Angular contact ball bearings

The main purpose:

Single column: machine tool spindle, high frequency motor, gas turbine, centrifugal separator, small car front wheel, differential pinion shaft.

Double column: oil pump, Roots blower, air compressor, various transmissions, fuel injection pump, printing machinery.

2. Self-aligning ball bearings

Double rows of steel balls, the raceway of the outer ring is an inner spherical type, so it can automatically adjust the misalignment of the shaft caused by the deflection or misalignment of the shaft or shell, and the bearing with a tapered hole can be easily installed on the shaft by using fasteners. withstand radial loads.

Self-aligning ball bearing

Main application: woodworking machinery, textile machinery transmission shaft, vertical self-aligning bearing with seat.

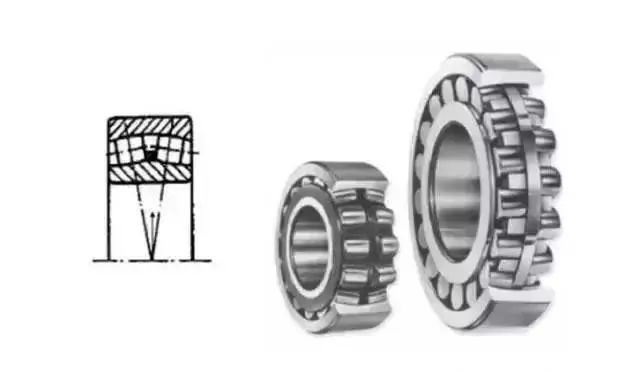

3. Spherical roller bearings

This type of bearing is equipped with spherical rollers between the outer ring of the spherical raceway and the inner ring of the double raceway. According to the different internal structures, it is divided into four types: R, RH, RHA and SR. The bearing center is consistent and has self-aligning performance, so it can automatically adjust the shaft center misalignment caused by the deflection or misalignment of the shaft or shell, and can bear radial load and bidirectional axial load.

Spherical roller bearing

Main applications: papermaking machinery, deceleration devices, railway vehicle axles, rolling mill gearbox seats, rolling mill roller tables, crushers, vibrating screens, printing machinery, woodworking machinery, various industrial reducers, vertical self-aligning bearings with seats.

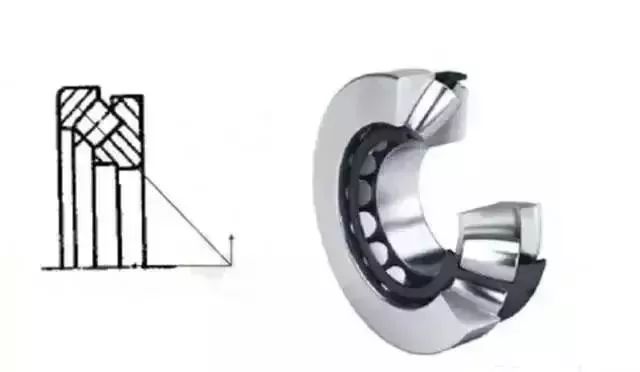

4. Thrust self-aligning roller bearing

The spherical rollers in this type of bearing are arranged obliquely.Because the raceway surface of the seat ring is spherical and has self-aligning performance, it can allow the shaft to have a certain inclination, and the axial load capacity is very large.

Radial loads are generally lubricated with oil.

Thrust spherical roller bearings

Main applications: hydraulic generators, vertical motors, propeller shafts for ships, reducers for rolling screws in rolling mills, tower cranes, coal mills, extrusion machines, and forming machines.

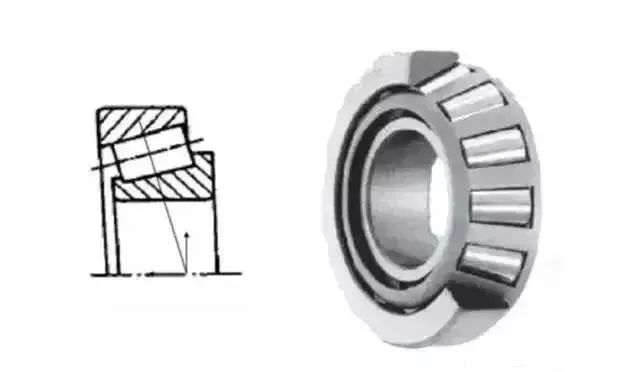

5. Tapered roller bearings

This type of bearing is equipped with truncated cylindrical rollers, and the rollers are guided by the large rib of the inner ring. The apex of each conical surface of the inner ring raceway surface, outer ring raceway surface and roller rolling surface intersects on the center line of the bearing in design. on point. Single-row bearings can bear radial loads and one-way axial loads, double-row bearings can bear radial loads and two-way axial loads, and are suitable for heavy loads and impact loads.

Tapered Roller Bearings

Main application: Automobile: front wheel, rear wheel, transmission, differential pinion shaft. Machine tool spindles, construction machinery, large agricultural machinery, gear reduction devices for railway vehicles, roll necks and reduction devices for rolling mills.

What is the connection between bearings and CNC?

Bearing and CNC machining are closely connected in modern manufacturing processes. CNC (Computer Numerical Control) machines are used to control and automate the machining process, using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create highly precise parts and products. Bearings are an essential component of the spindle and linear motion systems of CNC machines, providing support and reducing friction between rotating parts. This allows for smooth and accurate movement of the cutting tool or workpiece, resulting in precise cuts and high-quality finished products.

CNC machining and bearing technology have greatly improved manufacturing efficiency and accuracy, allowing manufacturers to produce complex parts with tight tolerances at a much faster rate than traditional machining methods. Overall, the combination of CNC machining parts and bearing technology has transformed modern manufacturing and enabled the production of high-quality parts and products at a large scale.

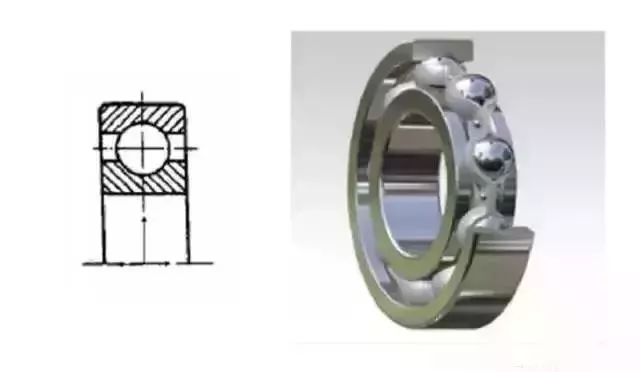

6. Deep groove ball bearings

Structurally, each ring of the deep groove ball bearing has a continuous groove type raceway with a cross section of about one-third of the equatorial circumference of the ball. Deep groove ball bearings are mainly used to bear radial loads, and can also bear certain axial loads.

When the radial clearance of the bearing increases, it has the properties of an angular contact ball bearing and can bear alternating axial loads in two directions. Compared with other types of bearings with the same size, this type of bearing has a small friction coefficient, high limit speed, and high precision. It is the preferred bearing type for users when selecting models.

Deep Groove Ball Bearings

Main applications: automobiles, tractors, machine tools, motors, water pumps, agricultural machinery, textile machinery, etc.

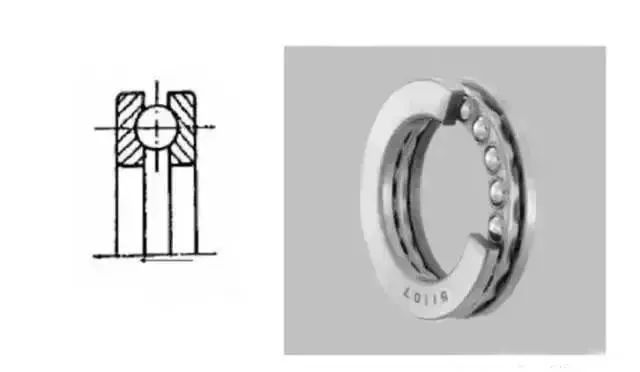

7. Thrust ball bearings

It consists of a washer-shaped raceway ring with a raceway, a ball and a cage assembly. The raceway ring that matches the shaft is called the shaft ring, and the raceway ring that matches the housing is called the seat ring. Two-way bearings match the secret shaft of the middle ring, one-way bearings can bear one-way axial loads, and two-way bearings can bear two-way axial loads (neither of them can bear radial loads).

Thrust ball bearing

Main application: automobile steering pin, machine tool spindle.

8. Thrust roller bearings

Thrust roller bearings are used to bear axial load-based shafts, combined warp load, but the warp load must not exceed 55% of the axial load. Compared with other thrust roller bearings, this kind of bearing has lower friction coefficient, higher speed and self-aligning ability. The rollers of the 29000 type bearings are asymmetrical spherical rollers, which can reduce the relative sliding between the stick and the raceway during work, and the rollers are long, large in diameter, and the number of rollers is large. The load capacity is large, and oil lubrication is usually used. Grease lubrication is available at low speeds.

Thrust Roller Bearings

Main application: hydroelectric generator, crane hook.

9. Cylindrical roller bearings

The rollers of cylindrical roller bearings are usually guided by two ribs of a bearing ring, and the cage roller and guide ring form an assembly that can be separated from the other bearing ring, which is a separable bearing.

This kind of bearing is easy to install and disassemble, especially when the inner and outer rings and the shaft and housing are required to have an interference fit. Such bearings are generally only used to bear radial loads, and only single-row bearings with ribs on both inner and outer rings can bear small steady axial loads or large intermittent axial loads.

Cylindrical Roller Bearings

Main applications: large motors, machine tool spindles, axle boxes, diesel engine crankshafts, automobiles, gearboxes, etc.

10. Four-point contact ball bearings

It can bear radial load and bi-directional axial load. A single bearing can replace the angular contact ball bearings combined in front or back. It is suitable for bearing pure axial load or synthetic load with a large axial load component. This type of bearing can withstand any direction One of the contact angles can be formed when the axial load is applied, so the ring and the ball are always in contact with two sides and three points on any contact line.

Four point contact ball bearings

Main applications: aircraft jet engines, gas turbines.

11. Thrust cylindrical roller bearings

It consists of washer-shaped raceway rings (shaft rings, seat rings) with cylindrical rollers and cage assemblies. Cylindrical rollers are processed with convex surfaces, so the pressure distribution between the rollers and the raceway surface is uniform, and can bear unidirectional axial loads. The axial load capacity is large and the axial rigidity is also strong.

Thrust Cylindrical Roller Bearings

Main applications: oil drilling rigs, iron and steel machinery.

12. Thrust needle roller bearings

Separable bearings are composed of raceway rings, needle rollers and cage assemblies, which can be combined with thin raceway rings processed by stamping or thick raceway rings processed by cutting. Non-separable bearings are integrated bearings composed of precision stamped raceway rings, needle rollers and cage assemblies, which can withstand unidirectional axial loads. This type of bearing occupies a small space and is conducive to the compact design of machinery. Only the needle roller and cage assembly are used, and the mounting surface of the shaft and the housing is used as the raceway surface.

Thrust Needle Roller Bearings

Main application: Transmission devices for automobiles, cultivators, machine tools, etc.

13. Thrust tapered roller bearings

This type of bearing is equipped with truncated cylindrical rollers (the big end is a spherical surface), and the rollers are accurately guided by the ribs of the raceway ring (shaft ring, seat ring). The vertices of each conical surface intersect at a point on the center line of the bearing. One-way bearings can bear one-way axial loads, and two-way bearings can bear two-way axial loads.

Thrust Tapered Roller Bearings

The main purpose:

One-way: crane hook, oil drilling rig swivel.

Bidirectional: rolling mill roll neck.

14. Outer spherical ball bearing with seat

The outer spherical ball bearing with seat is composed of an outer spherical ball bearing with seals on both sides and a cast (or stamped steel) bearing seat. The internal structure of the outer spherical ball bearing is the same as that of the deep groove ball bearing, but the inner ring of this kind of bearing is wider than the outer ring, and the outer ring has a truncated spherical outer surface, which can be automatically aligned when matched with the concave spherical surface of the bearing seat.

In CNC turning, bearings play a crucial role in ensuring the accuracy and quality of the finished parts. CNC turning is a process where a cutting tool removes material from a rotating workpiece to create a desired shape or form. Bearings are used in the spindle and linear motion systems of the CNC lathe to support the rotating workpiece and the cutting tool. By reducing friction and providing support, bearings allow the cutting tool to move smoothly and precisely along the surface of the workpiece, creating accurate and uniform cuts. This results in consistent, high-quality parts that meet the required specifications.

CNC turning and bearing technology have revolutionized the manufacturing industry, making it possible to produce complex parts with tight tolerances and high efficiency.

Anebon provide excellent toughness in excellent and advancement, merchandising, gross sales and promoting and operation for OEM/ODM Manufacturer Precision Iron Stainless Steel. Since the manufacturing unit founded, Anebon have now committed into the progress of new goods. Along with the social and economic pace, we’ll continue to carry forward the spirit of “high excellent, efficiency, innovation, integrity”, and stay with the operating principle of “credit initially, customer 1st, good quality excellent”. Anebon will produce a excellent foreseeable future in hair output with our companions.

OEM/ODM Manufacturer China Casting and Steel Casting, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes Anebon become superior supplier of the four major product categories, such as CNC machining, CNC milling parts, CNC turning and metal castings.

Post time: Apr-10-2023