News

-

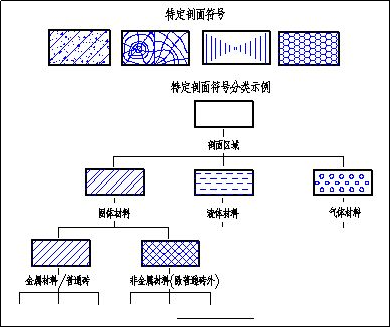

CNC Tool Material & Selection Encyclopedia

What is a CNC tool? The combination of advanced processing equipment and high-performance CNC cutting tools can give full play to its due performance and achieve good economic benefits. With the rapid development of cutting tool materials, various new cutting tool materials have greatly impro...Read more -

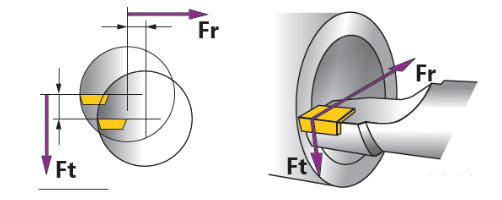

Calculation method of eccentric parts of CNC lathe

What are eccentric parts? Eccentric parts are mechanical components that have an off-center axis of rotation or an irregular shape that causes them to rotate in a non-uniform manner. These parts are often used in machines and mechanical systems where precise movements and control are required. On...Read more -

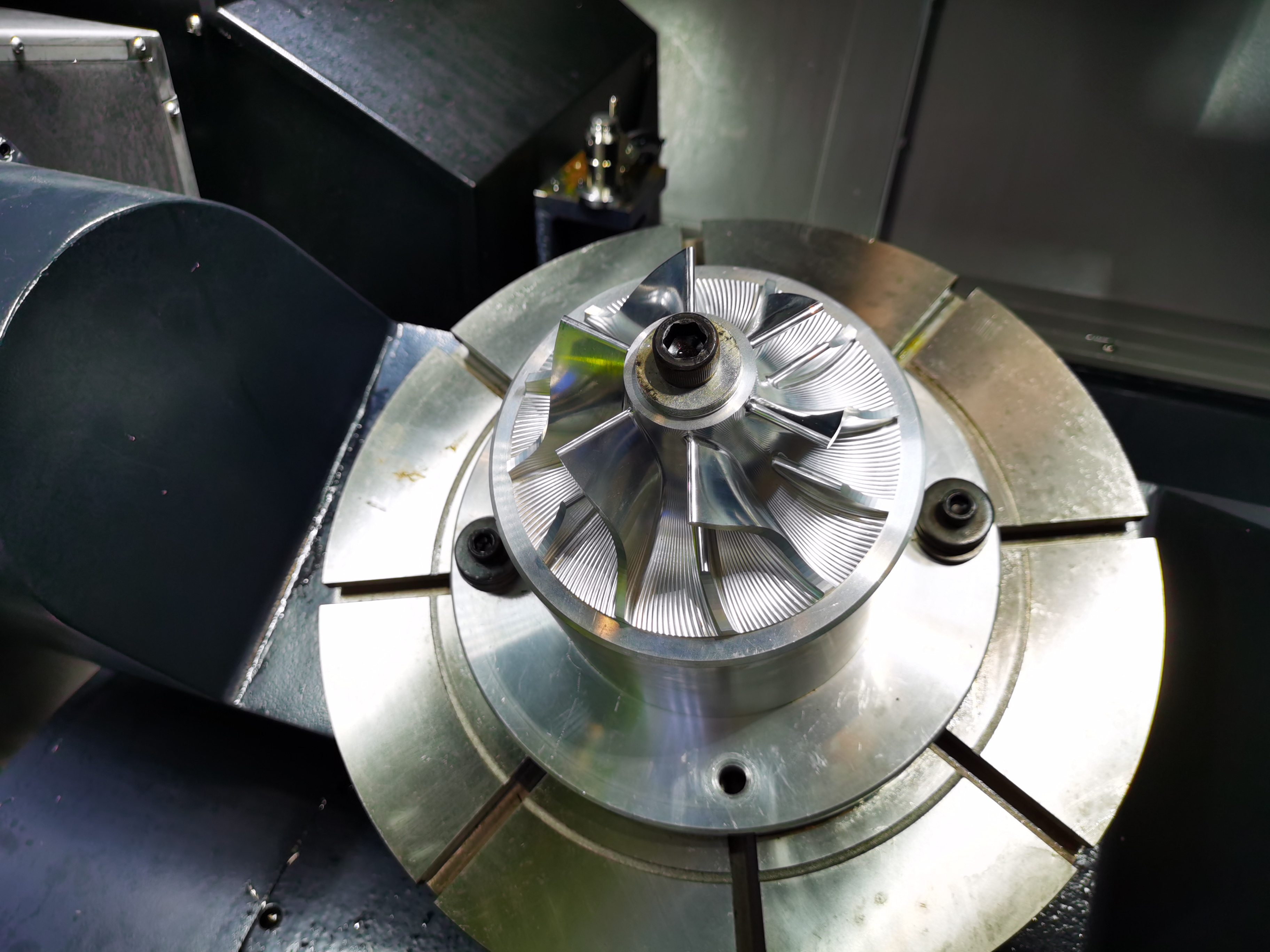

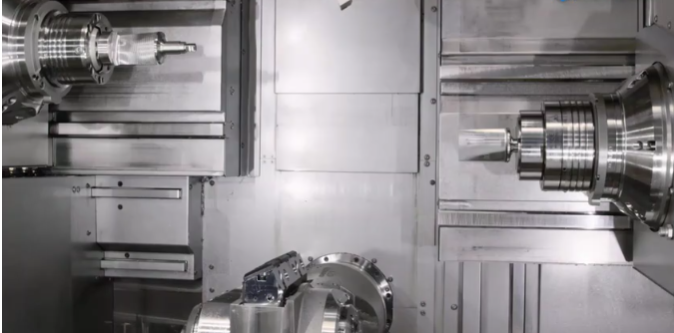

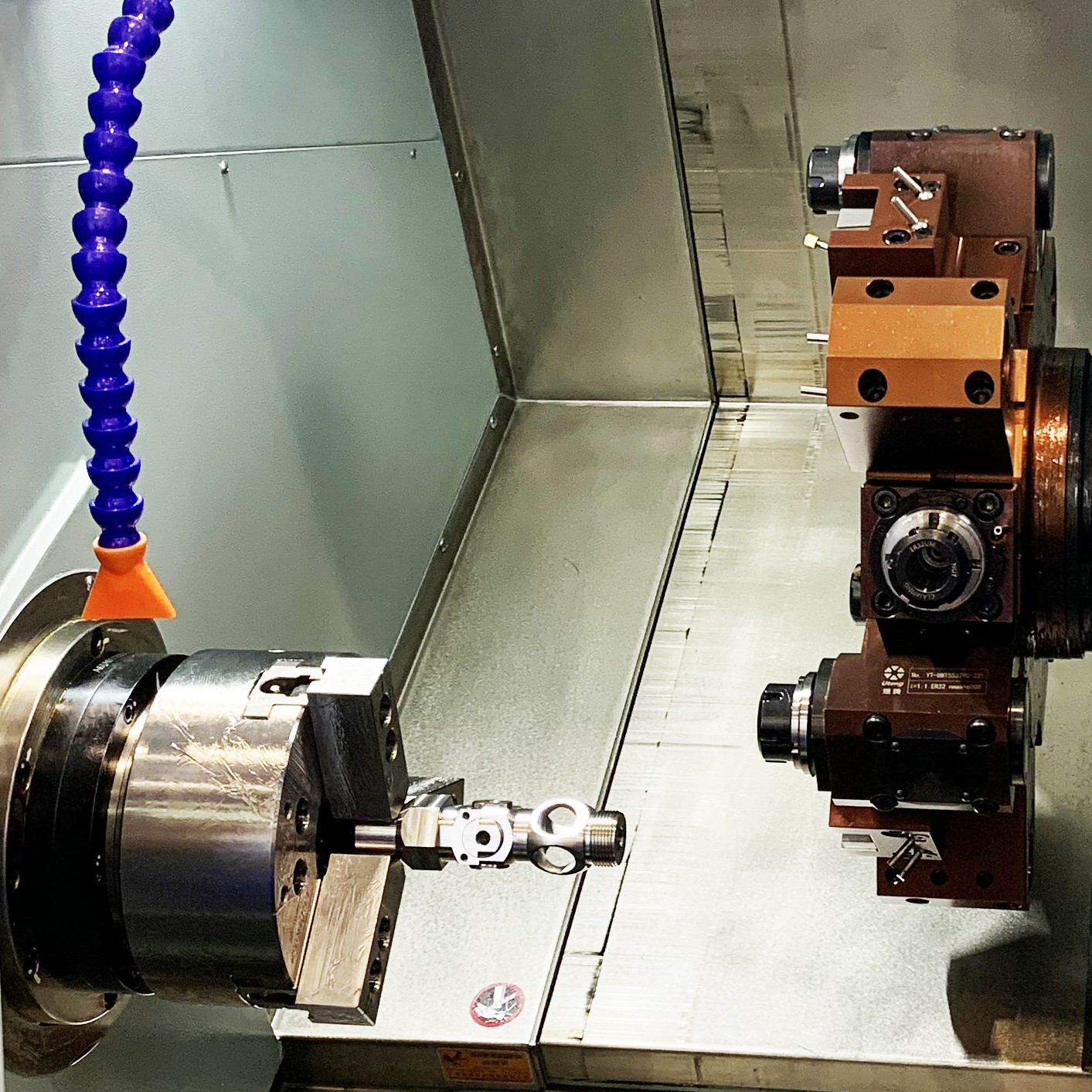

What is CNC machining?

CNC machining (Computer Numerical Control machining) is a manufacturing process that involves the use of computer-controlled machines to create precise parts and components from a variety of materials. It is a highly automated process that involves the use of CAD (Computer-Aided Design) software ...Read more -

The characteristics and differences of quenching cracks, forging cracks and grinding cracks

Quenching cracks are common quenching defects in CNC machining, and there are many reasons for them. Because heat treatment defects start from product design, Anebon believes that the work of preventing cracks should start from product design. It is necessary to correctly select materials, reason...Read more -

Process measures and operating skills to reduce deformation during CNC machining of aluminum parts!

Anebon’s other peer factories often encounter the problem of processing deformation when processing parts, the most common of which are stainless steel materials and aluminum parts with low density. There are many reasons for the deformation of custom aluminum parts, which are related to th...Read more -

CNC machining knowledge that cannot be measured by money

1 Influence on cutting temperature: cutting speed, feed rate, back cutting amount. Influence on cutting force: back cutting amount, feed rate, cutting speed. Influence on tool durability: cutting speed, feed rate, back cutting amount. 2 When the amount of back engagement doubles, the cutting forc...Read more -

The meaning of 4.4, 8.8 on the bolt

I have been doing machinery for so many years, and have processed various machining parts, turning parts and milling parts through CNC machine tools and precision equipment. There is always one part that is essential, and that is the screw. The performance grades of bolts for steel structure con...Read more -

The tap and drill bit are broken in the hole, how to fix it?

When the factory is processing CNC machining parts, CNC turning parts and CNC milling parts, it often encounters the embarrassing problem that the taps and drills are broken in the holes. The following 25 solutions are compiled for reference only. 1. Fill some lubricating oil, use a pointed hairp...Read more -

Thread calculation formula

Everyone is familiar with the thread. As colleagues in the manufacturing industry, we often need to add threads according to customer needs when processing hardware accessories such as CNC machining parts, CNC turning parts and CNC milling parts. 1. What is thread?A thread is a helix cut into a w...Read more -

A large collection of tool setting methods for machining centers

1. Z-direction tool setting of machining center There are generally three methods for Z-direction tool setting of machining centers:1) On-machine tool setting method 1This tool setting method is to sequentially determine the mutual positional relationship between each tool and the workpiece in th...Read more -

CNC Frank system command analysis, come and review it.

G00 positioning1. Format G00 X_ Z_ This command moves the tool from the current position to the position specified by the command (in absolute coordinate mode), or to a certain distance (in incremental coordinate mode). 2. Positioning in the form of non-linear cutting Our definition is: use an in...Read more -

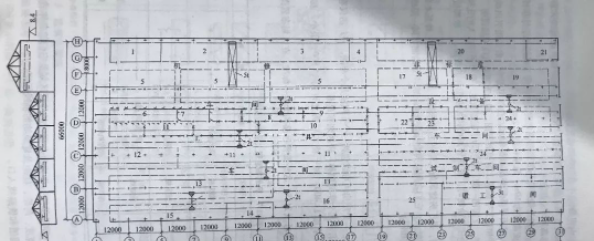

Key points of fixture design

The fixture design is generally carried out according to the specific requirements of a certain process after the machining process of cnc machining parts and cnc turning parts is formulated. When formulating the process, the possibility of fixture realization should be fully considered, and when...Read more