News

-

Normalizing, annealing, quenching, tempering.

The difference between annealing and tempering is:Simply put, annealing means not having hardness, and tempering still retains a certain hardness. Tempering: The structure obtained by high temperature tempering is tempered sorbite. Generally, tempering is not used alone. The main purpose of t...Read more -

Basic knowledge of mechanical drawing | Detailed introduction with pictures and texts

1. Function and content of part drawing 1. The role of part drawings Any machine is composed of many parts, and to manufacture a machine, the parts must be manufactured first. The part drawing is the basis for manufacturing and inspecting the parts. It puts forward certain requirements for the...Read more -

More complete technical specifications for mechanical assembly | Machinist Collection

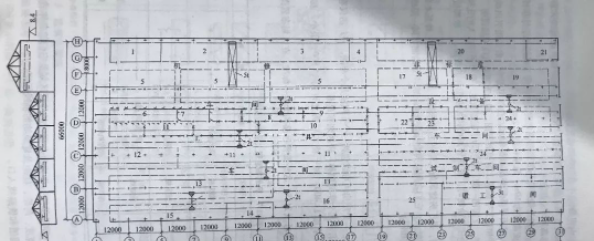

Homework preparation (1) Operation data: Including general assembly drawings, component assembly drawings, parts drawings, material BOM, etc., until the end of the project, the integrity and cleanliness of the drawings and the integrity of the process information records must be guaranteed. (2) ...Read more -

201, 202, 301, 302, 304 which is a good steel? | Stainless Steel Encyclopedia

Stainless steel is a popular material used in machining due to its strength, durability, and resistance to corrosion. However, it can also present challenges in the machining process due to its hardness and work-hardening tendencies. Here are some important considerations when machinin...Read more -

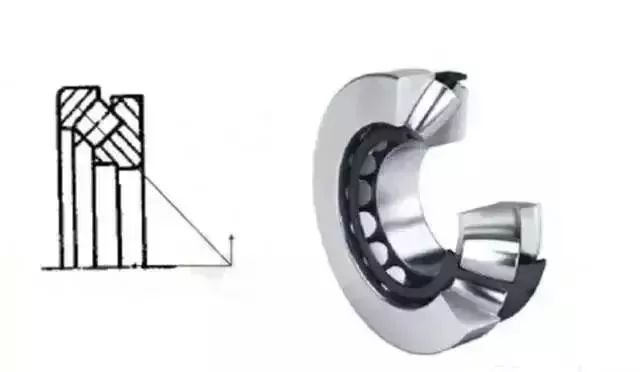

The characteristics, differences and uses of fourteen kinds of bearings | An overview of this article

What is a bearing? Bearings are parts that support the shaft, used to guide the rotational movement of the shaft, and bear the load transmitted from the shaft to the frame. Bearings are widely used and demanding supporting parts and basic parts in the machinery industry. They are the support...Read more -

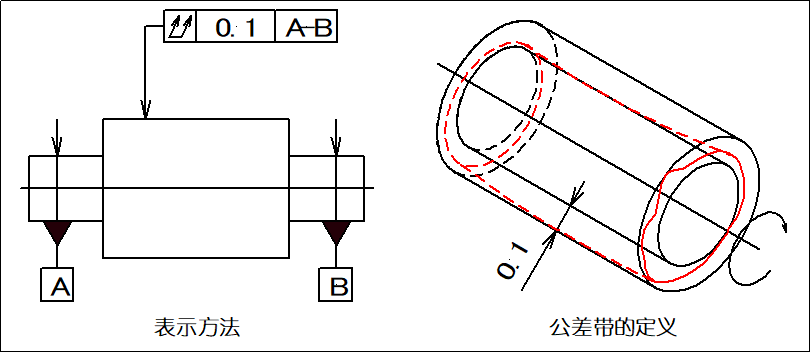

Straightness, flatness, roundness, cylindricity… Do you know all these Tolerance of Form and Position well?

Do you know what Tolerance of Form and Position is? Geometric tolerance refers to the allowable variation of the actual shape and actual position of the part from the ideal shape and ideal position. Geometric tolerance includes shape tolerance and position tolerance. Any part is co...Read more -

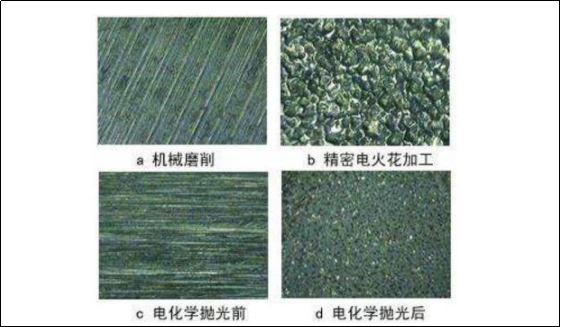

Surface Roughness Encyclopedia

1. The concept of metal surface roughness Surface roughness refers to the unevenness of small pitches and tiny peaks and valleys that a machined surface has. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic ge...Read more -

What should you do if the workpiece is deformed, pinched, or dimensionally unstable during processing?

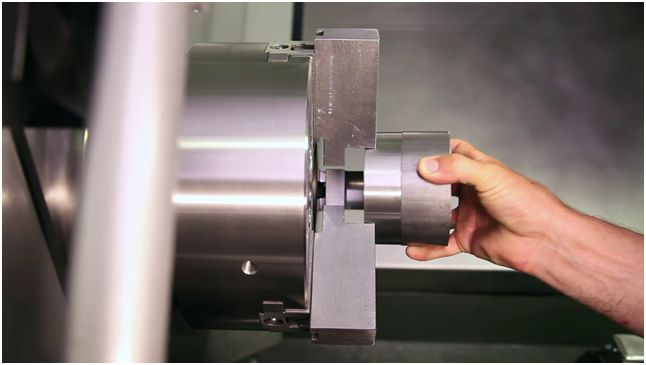

Indispensable Fixtures for CNC Machining — Soft Jaws The soft claw can ensure the repeated positioning accuracy of the workpiece to the greatest extent, so that the centerline of the processed workpiece can completely coincide with the centerline of the spindle, and the flat surface on ...Read more -

CNC Tool Material & Selection Encyclopedia

What is a CNC tool? The combination of advanced processing equipment and high-performance CNC cutting tools can give full play to its due performance and achieve good economic benefits. With the rapid development of cutting tool materials, various new cutting tool materials have greatly impro...Read more -

Calculation method of eccentric parts of CNC lathe

What are eccentric parts? Eccentric parts are mechanical components that have an off-center axis of rotation or an irregular shape that causes them to rotate in a non-uniform manner. These parts are often used in machines and mechanical systems where precise movements and control are required. On...Read more -

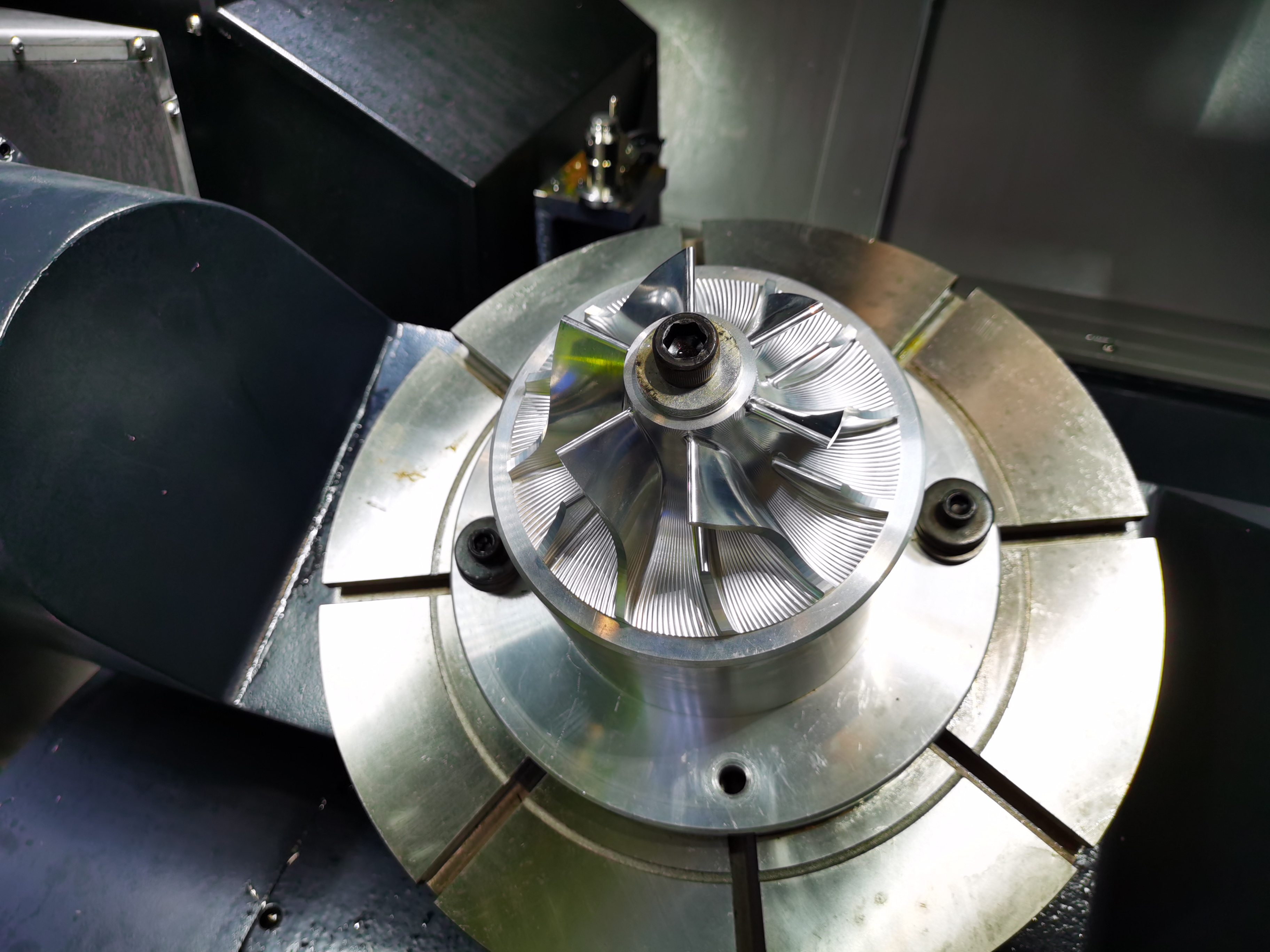

What is CNC machining?

CNC machining (Computer Numerical Control machining) is a manufacturing process that involves the use of computer-controlled machines to create precise parts and components from a variety of materials. It is a highly automated process that involves the use of CAD (Computer-Aided Design) software ...Read more -

The characteristics and differences of quenching cracks, forging cracks and grinding cracks

Quenching cracks are common quenching defects in CNC machining, and there are many reasons for them. Because heat treatment defects start from product design, Anebon believes that the work of preventing cracks should start from product design. It is necessary to correctly select materials, reason...Read more