News

-

Positioning reference and fixtures and the use of commonly used gauges

1, the concept of positioning benchmark The datum is the point, line, and surface on which the part determines the location of other points, lines, and faces. The reference used for positioning is called the positioning reference. Positioning is the process of determining the correct position of ...Read more -

CNC Turning Machine

(1) Type of lathe There are many types of lathes. According to the statistics of a mechanical processing technician’s manual, there are 77 kinds of typical types: instrument lathes, single-axis automatic lathes, multi-axis automatic or semi-automatic lathes, return wheels or turret lathes....Read more -

Buying Machine Tools: Foreign Or Domestic, New Or Used?

The last time we discussed machine tools, we talked about how to choose the size of the new metalworking lathe that your wallet is itching to pour itself into. The next big decision to make is “new or used?” If you’re in North America, this question has a lot of overlap with the classic question...Read more -

At PMTS 2019, Attendees Met Best Practices, Best Technology

The challenge to Anebon Metal Co, Ltd is to meet demand for increasingly complex parts produced in shorter production runs, often in families of parts for the automotive, aerospace, hydraulics, medical device, energy and electronics industries as well as general engineering. The machine tool...Read more -

Removing Microburrs from Small

There is considerable debate in online forums about the best techniques for removing burrs created during the machining of threaded parts. Internal threads—whether cut, rolled, or cold-formed—often have burrs at the entrances and exits of holes, on thread crests, and along slot edges. Extern...Read more -

High Precision Technical Support

On June 6, 2018, our Swedish customer encountered an urgent incident. His client needed him to design a product for the current project within 10 days. By chance he found us, then we chat in e-mailsand collect a lot of idea from him. Finally we designed a prototype which was fit his project withi...Read more -

Sleek and Stylish Swiss Precision for Milling/Turning | Starrag

Among luxury watchmakers there is much appreciation for the case for the new UR-111C wristwatch, which is just 15 mm high and 46 mm wide, and does not require a screw-on bottom plate. Instead, the case is cut as a single piece from an aluminum blank and includes a 20-mm-deep side compartment...Read more -

China Heat sink, Aluminum 6061 Extrusion and CNC Machined Part with Passivatiom Surface Treatment on Global Sources

Products we provide:-Material: aluminum alloy 6061T6 -Tolerance: 0.05mm-Finishing: anodize/painting/powder coasting-Edges and holes are debarred-Surfaces are free of scratches-Material capabilities: aluminum, stainless steel, copper, plas...Read more -

CJR Propulsion launches two-week design and production service for propellers

The reduction in lead times for propellers up to 1.5 meters in diameter has been achieved through an end-to-end design and production solution that is able to support boat owners and operators in their most challenging moments. By combining 3D mobile scanning, computational fluid dynamics an...Read more -

3D Printing and the Circular Economy

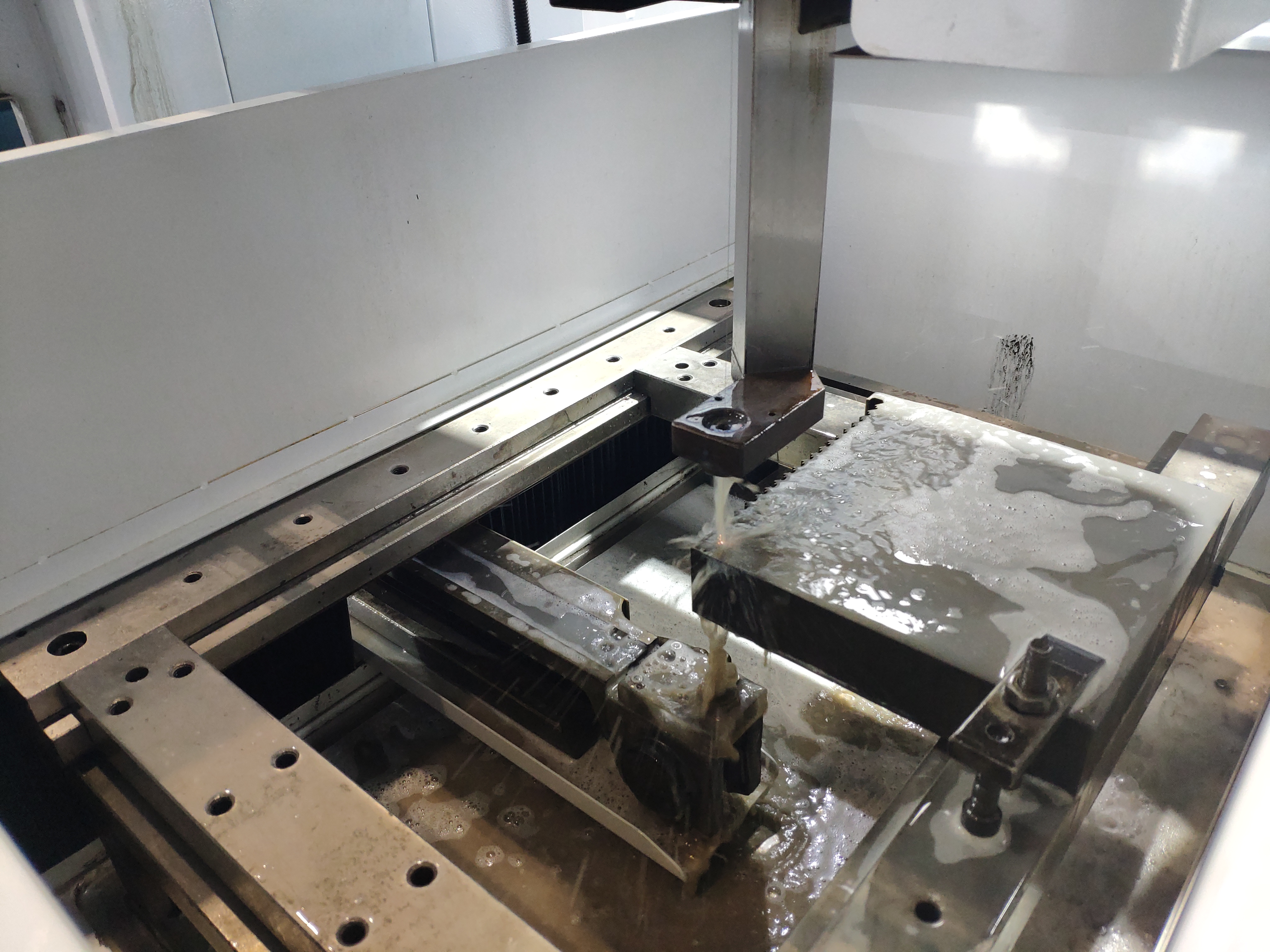

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting ta...Read more -

Common methods for ensuring machining accuracy of CNC lathes

Content Menu ● Understanding CNC Lathe Accuracy● Key Techniques for Enhancing CNC Lathe Accuracy● Comparison of Machining Techniques● Visual Aids and Videos● Common Challenges in Achieving Accuracy● Conclusion● Questions & Answers CNC (Computer Numerical Control) lathes are pivotal in modern...Read more