News

-

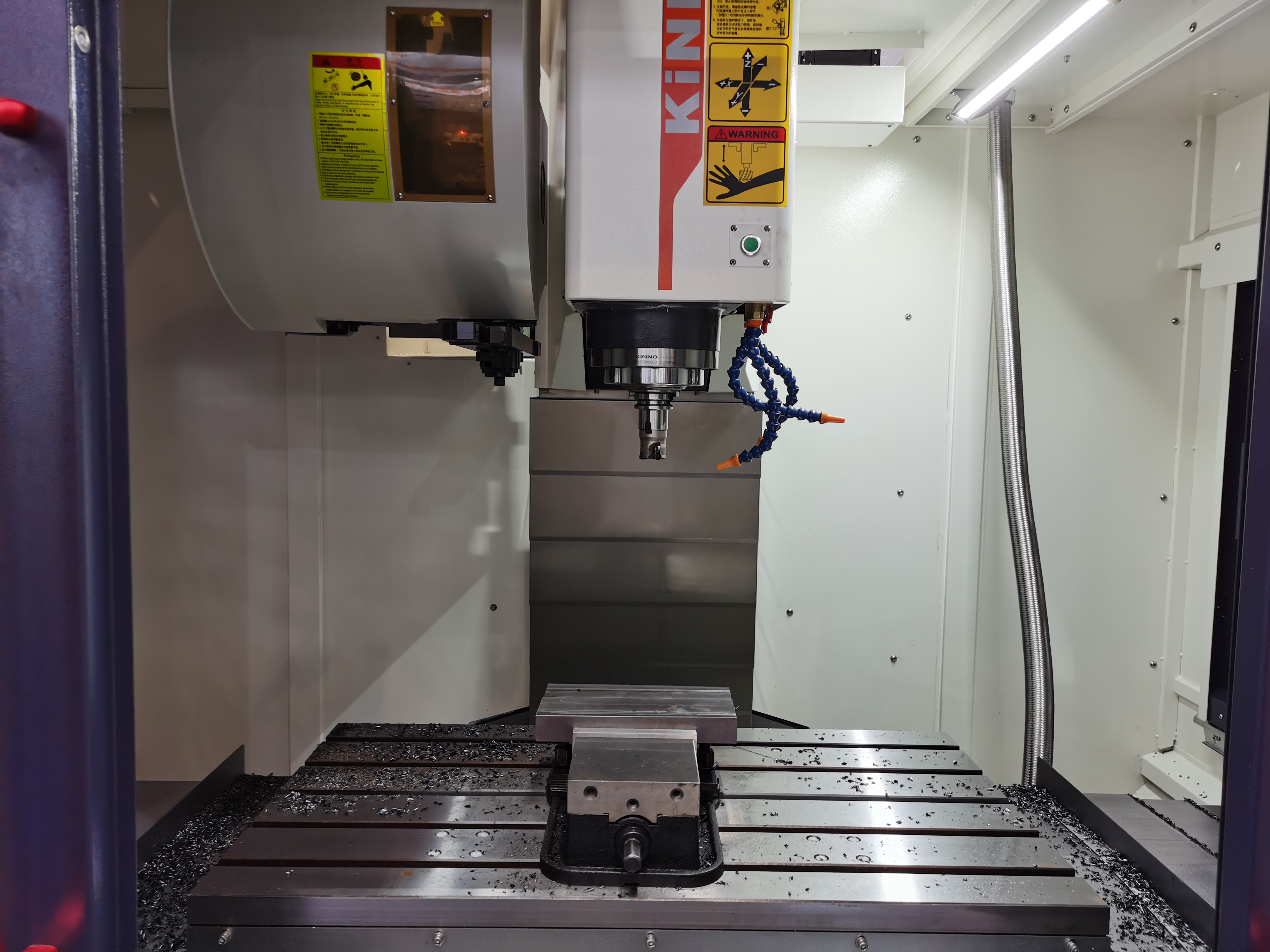

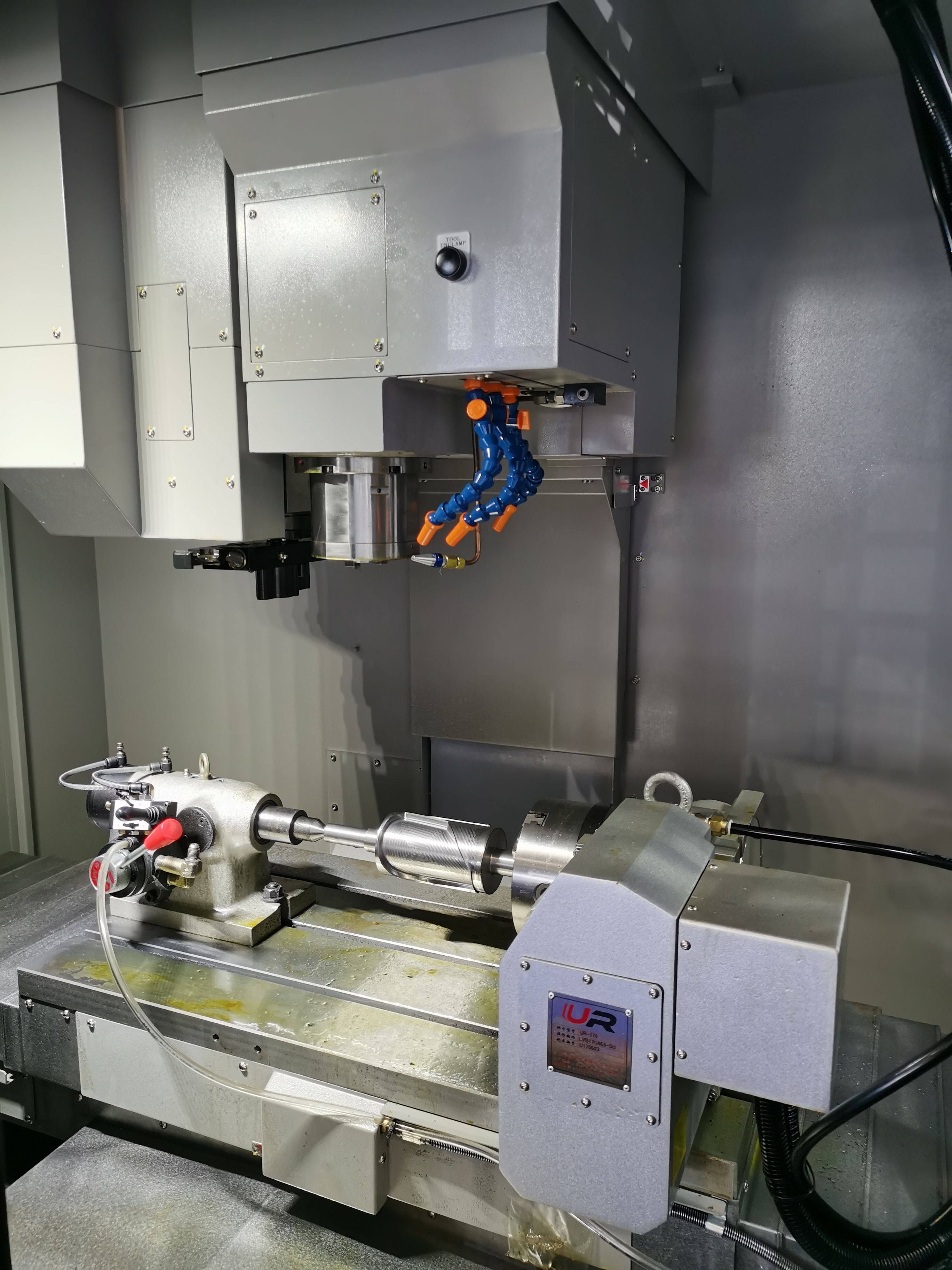

Installation of CNC milling machine

I. Installation of numerical control milling machine: A general numerical control milling machine is designed with mechanical and electrical integration. It is shipped as a complete machine without disassembly and packaging from the manufacturer to the user. Therefore, after receiving the m...Read more -

The ten most commonly used jigs in CNC

Fixture refers to the device used to fix the processing object in the mechanical manufacturing process so that it occupies the correct position to accept construction or detection. In a broad sense, any method in the process that is used to install a workpiece quickly, conveniently, and safely ca...Read more -

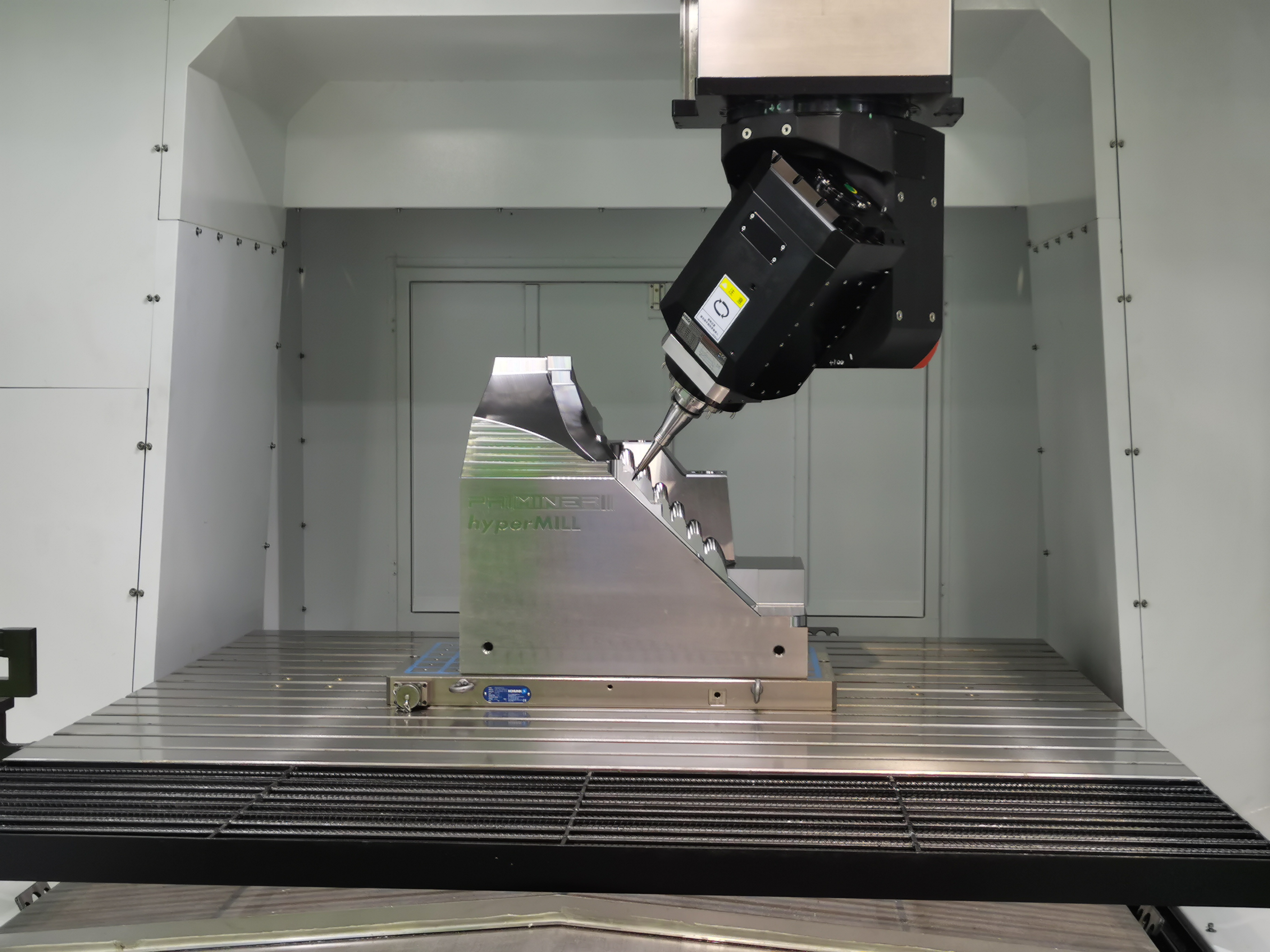

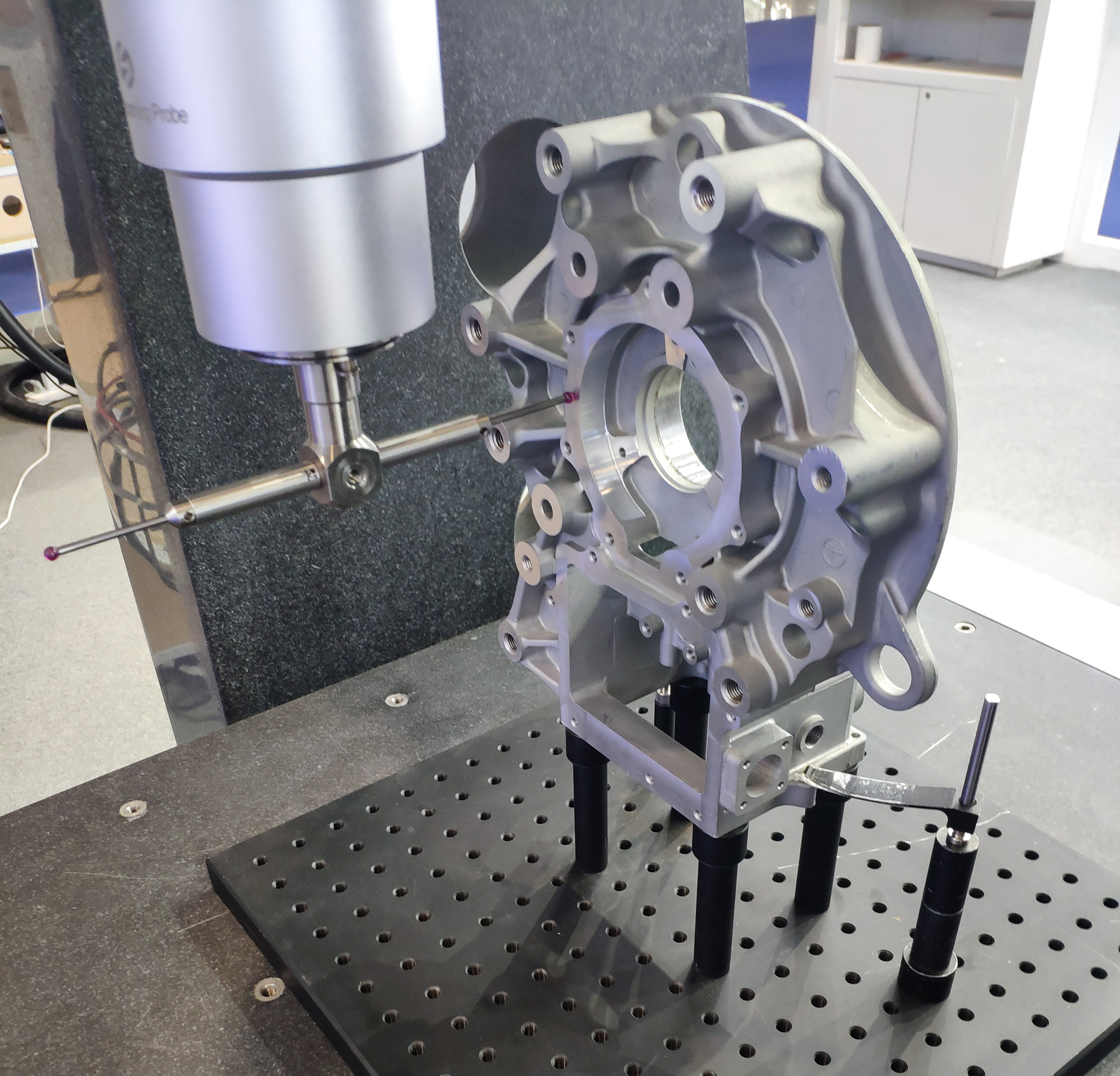

What is the relationship between the machining accuracy of the mould in CNC machining center?

In the process of machining mold, the machining center has higher and higher requirements for accuracy and surface machining quality. To ensure the machining quality of the mold, we should consider the selection of machine tool, tool handle, tool, machining scheme, program generation, operat...Read more -

Several Common Surface Treatments

Anodizing: It mainly anodizes aluminum. It uses the electrochemical principle to form a layer of Al2O3 (alumina) film on the surface of aluminum and aluminum alloy. The oxide film has unique characteristics such as protection, decoration, insulation, wear resistance, etc. Technological p...Read more -

Analysis of plastic surface treatment technology

1. Frosted Frosted plastic generally refers to plastic film or sheet. When rolling, there are various lines on the roller. The different lines reflect the transparency of the material. 2. Polishing Polishing refers to the machining method of using mechanical, chemical, or electrochemi...Read more -

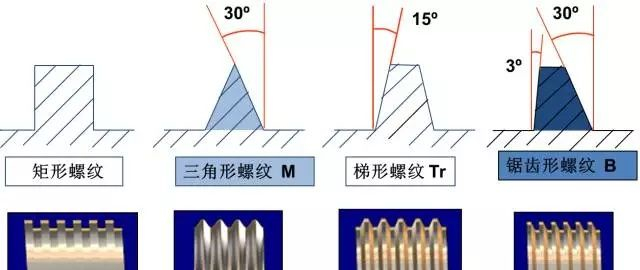

Elements of thread

Elements of thread The thread includes five elements: profile, nominal diameter, number of lines, pitch (or lead), and direction of rotation. CNC machining part 1. tooth type The profile shape of the thread is called the profile shape on the section area passing through the thread axis. There a...Read more -

7 Thread Processing Methods

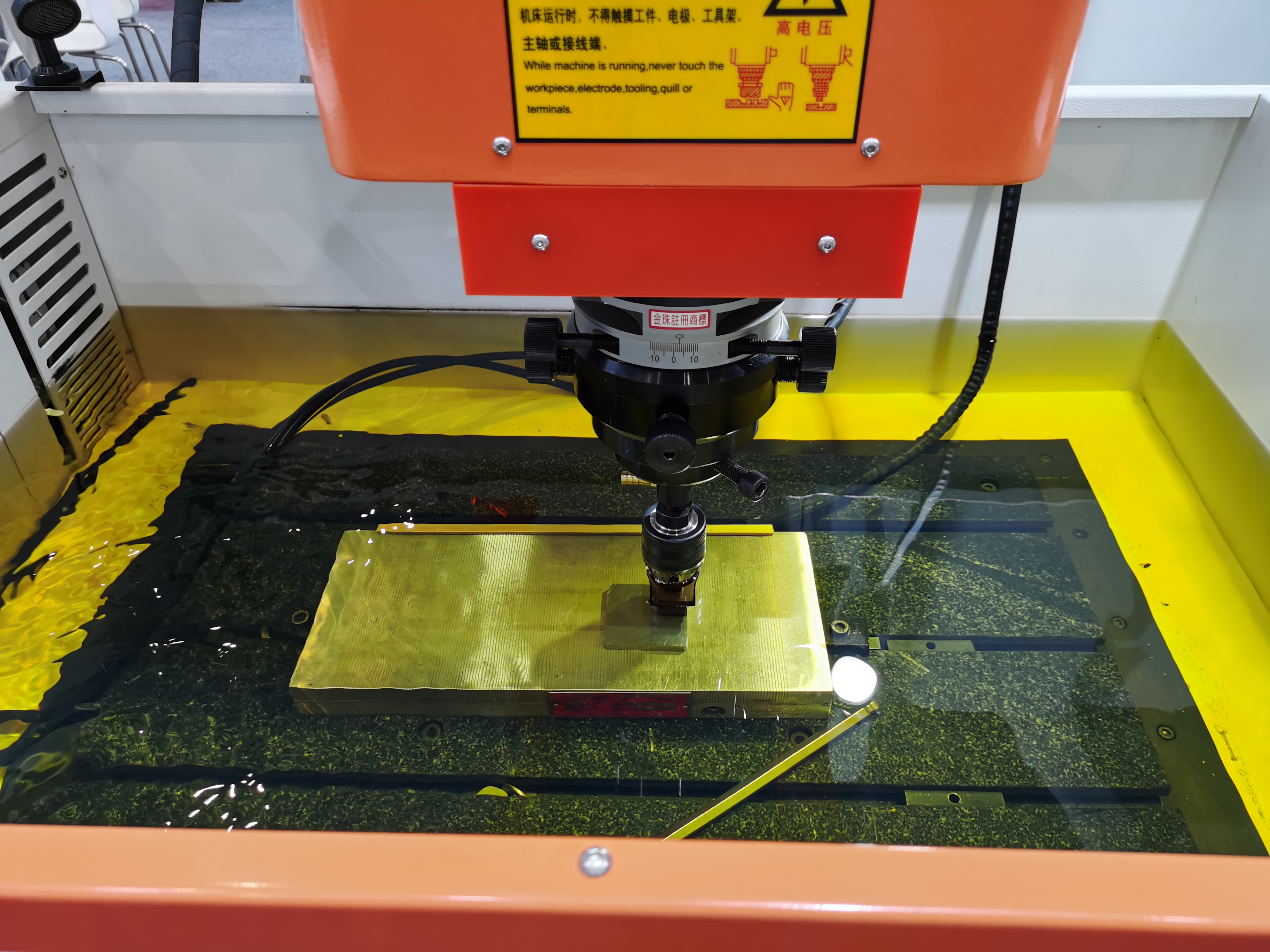

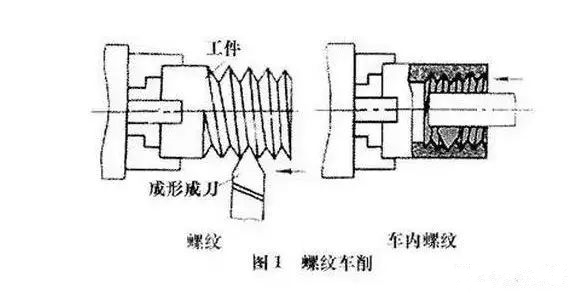

1. Thread cutting Generally, it refers to machining thread on the workpiece with a forming or grinding tool, mainly including turning, milling, tapping and threading grinding, grinding, whirlwind cutting, etc. When turning, milling, and grinding the thread, the transmission chain of the machine t...Read more -

The method of processing various internal and external threads with thread processing tools.

One thread cutting Generally, it refers to machining thread on the workpiece with a forming or grinding tool, mainly including turning, milling, tapping and threading grinding, grinding, whirlwind cutting, etc. When turning, milling, and grinding the thread, the transmission chain of the mac...Read more -

Five important knowledge points of CNC machining, novices need to keep in mind

1. What is the role of the processing program? The machining program list is one of the contents of the NC machining process design. It is also a procedure that requires the operator to follow and execute. It is a specific description of the machining program. The purpose is to let th...Read more -

What Are The Technical Requirements For Metal Stamping?

What are the technical requirements for metal stamping? I. Raw Material Properties of Hardware Stamping Parts 1. Chemical analysis and metallographic examination The content of chemical elements in the material was analyzed, the grain size and uniformity of the material were determined, the gra...Read more -

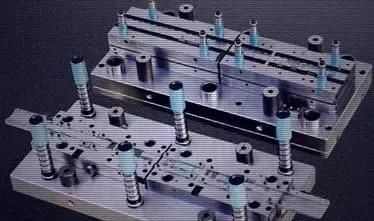

Why is the punch of stamping die easy to break?

Why is the punch of stamping die easy to break? In addition to the punch material and the design of the punch itself, what are the causes of the fracture of the punch? 1. Punch hardness is too high, the material of the punch is not right – change the material of the punch, adjust the hardne...Read more -

Surface Coating Classification

By paint: solvent-based paint coating, electrophoretic coating, powder coating According to painting method: air spraying, airless spraying, electrostatic spraying, electrophoresis According to the coating function: primer coating, intermediate coating, topcoat coating Process: pre-treatme...Read more