News

-

Thread milling pin Radial, arc, tangential approach, which is the most practical?

To achieve thread milling, the machine must have three-axis linkage. The helical interpolation is a function of CNC machine tools. The tool controls the tool to realize the helical trajectory. The helical interpolation is formed by the plane circular interpolation and the linear motion perpendicu...Read more -

Improvement of Equipment And Quote System in Anebon

Newly rebuilt bar machine to replace an old worn machine. We are expecting soon which will replace a much older piece. We replaced older multi spindle davenport’s with much newer better condition machines which will be more productive & hold better tolerance. Quote System Improved Computer Ai...Read more -

Introduction to dozens of common stamping procedures

The cold stamping die process is a metal processing method mainly aimed at metal materials. The material is forced to deform or separate by pressure equipment such as a punch to obtain product parts that meet actual requirements, referred to as stamped parts. There are many situations for the sta...Read more -

29 Pieces Of Mechanical CNC Machining Knowledge

1. In CNC machining, the following points should be paid special attention: (1) In China’s current economic CNC lathes, ordinary three-phase asynchronous motors achieve step-less speed change through inverters. If there is no mechanical deceleration, the output torque of the spindle is oft...Read more -

Fifteen important knowledge points of CNC programming CNC machining / CNC cutter

1. The most important tool in machining If any tool stops working, it means that production stops. But it doesn’t mean that every tool has the same importance. The tool with the longest cutting time has a greater impact on the production cycle, so on the same premise, more attention should ...Read more -

The difference between CNC machining center, engraving and milling machine and engraving machine

Engraving and milling machine As the name implies, it can be carved or milled. Based on the engraving machine, the spindle and servo motor power are increased, the bed is subjected to the force, and the spindle is kept at a high speed. The engraving and milling machine is also developing at a hi...Read more -

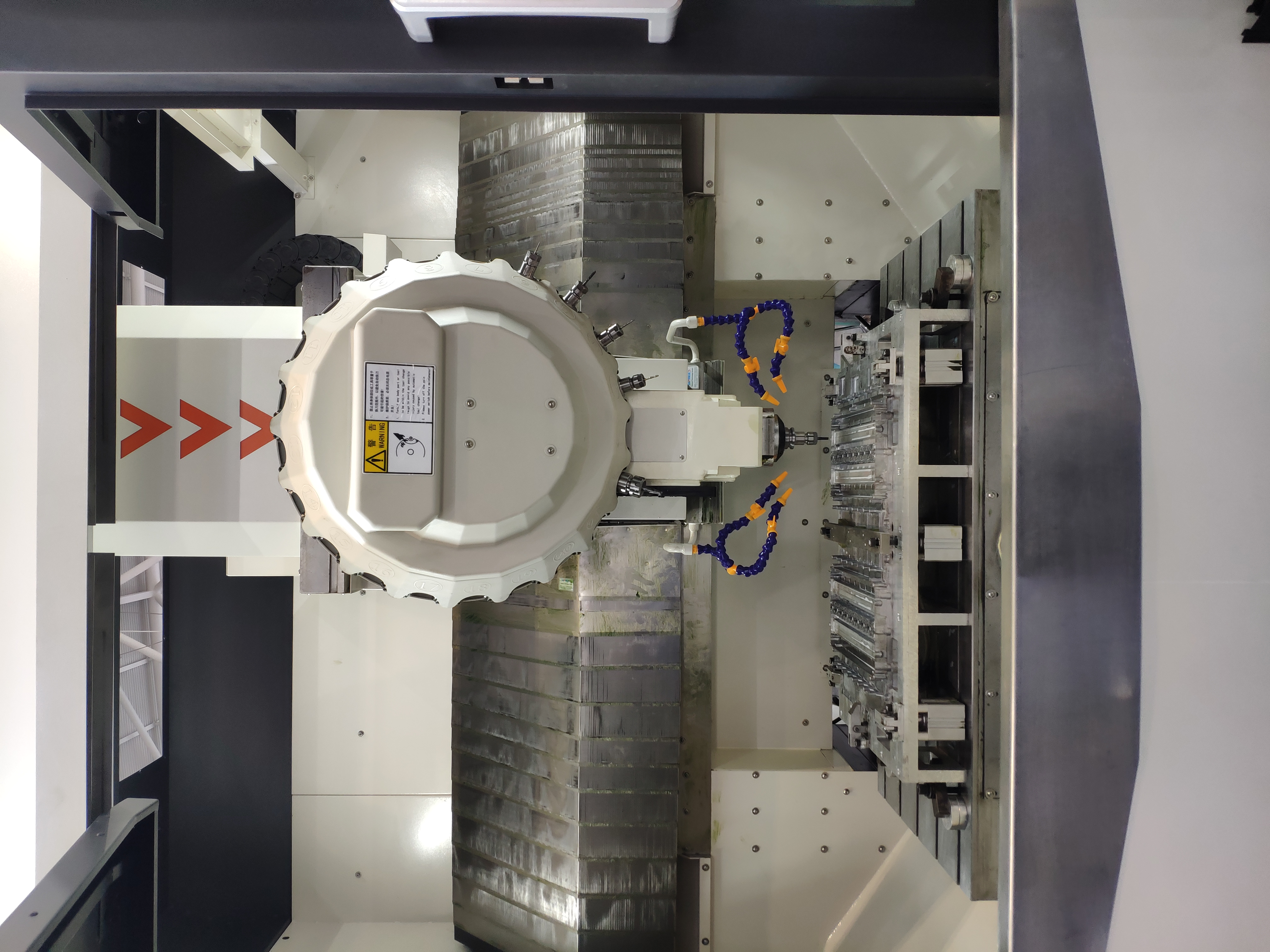

Working principle and fault handling of CNC machining center

First, the role of the knife The cutter cylinder is mainly used for the spindle cutter in the machining center machine tool, the CNC milling machine tool automatic or semi-automatic exchange mechanism. It can also be used as a clamping device of the clamp and other mechanisms. The 30# spindle ge...Read more -

CNC machining center needs to do these things well for metal cutting

First, the turning movement and the formed surface Turning movement: In the cutting process, the workpiece and the tool must be cut relative to each other to remove excess metal. The movement of the excess metal on the workpiece by the turning tool on the lathe is called turning motion, which ca...Read more -

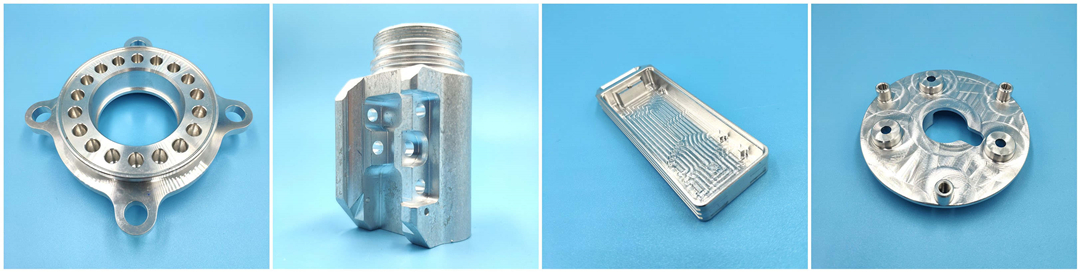

There are five ways to process aluminum alloy

1. Sandblasting is also called shot blasting The impact of high-speed sand flow causes cleaning and roughening of metal surfaces. This method of surface treatment of aluminum parts can make the surface of the workpiece get a certain degree of cleanliness and different roughness, imp...Read more -

How to calculate the cutting speed and feed speed of CNC machining center?

Cutting speed and feed speed of CNC machining center: 1: spindle speed = 1000vc / π D 2. Maximum cutting speed of general tools (VC): high-speed steel 50 m / min; super complex tool 150 m / min; coated tool 250 m / min; ceramic diamond tool 1000 m / min 3 processing alloy steel Brinell h...Read more -

Machining accuracy of CNC lathe

1. Accuracy of machine tool: if the minimum accuracy of machine tool is 0.01mm, you can’t process products with an accuracy of 0.001mm on the machine tool in any case. 2. Clamping: select appropriate clamping process according to workpiece material, with moderate clamping force. For example...Read more -

7 steps to operate CNC machining center

1. Startup preparation After each startup or emergency stop reset of the machine tool, please return to the reference zero position (i.e., return to zero) so the machine tool has a reference position for its subsequent operation. 2. Clamping workpieworkpiecere the workpieworkpiecemped, t...Read more