News

-

Customers from Europe visited Anebon

The purpose of Alex’s visit is to talk to us about improving the product. Jason personally went to the airport to pick him up to our company. After a formal visit to the company. Jason and Alex have a period of discussion.Finally we reached a consensus. Also Jason introduced him to many loc...Read more -

Customer From Germany Visit The Company For New Project

On May 15th, 2018, guests from Germany came to Anebon for a field trip. The company’s foreign trade department, Mr Jason Zeng warmly welcomed the guests. The purpose of this customer visit was to develop a new project, so Jason introduced the customer to the company and product information ...Read more -

Anebon Hardware Co., Ltd. obtained ISO9001:2015 “Quality Management System Certification”

On Nov. 21, 2019, Anebon passed the strict examination and approval of the application, submitted materials, review, certification, and publicity and filing, and all the audit items met the standards stipulated in the ISO9001:2015 quality management system and related requirements. This is an imp...Read more -

High Precision Technical Support

On June 6, 2018, our Swedish customer encountered an urgent incident. His client needed him to design a product for the current project within 10 days. By chance he found us, then we chat in e-mailsand collect a lot of idea from him. Finally we designed a prototype which was fit his project withi...Read more -

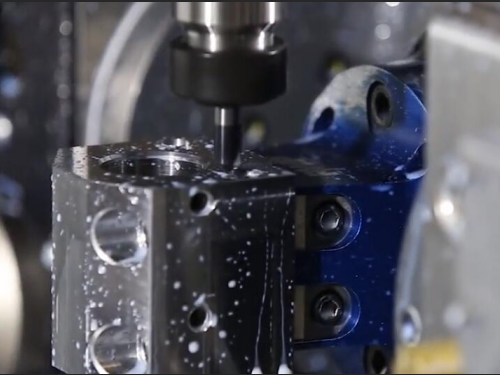

Precision And Powerful CNC Machine

Our factory is located in Fenggang Town, Guangdong. Our imported machines have 35 milling machines and 14 lathes. Our factory is strictly in accordance with ISO standards. Our machine tool is cleaned in two weeks, ensuring the accuracy of the machine while ensuring the environment of the factory....Read more -

Factory Environment in Anebon

Our factory environment is very beautiful, and all customers will praise our great environment when they come on the field trip. The factory covers an area of about 5,000 square meters. In addition to the factory building, there is a 3-storey dormitory. Looks very spectacular CNC machining part ...Read more -

Anebon Wish Every Customer Merry Christmas And Happy New Year

We value each and every one of our customers and cannot express our gratitude enough for your ongoing support. Anebon sincerely wishes you and your family a safe and happy Christmas, full of happy memories. We will maintain an excellent job in the new year and grow up with you. The bo...Read more -

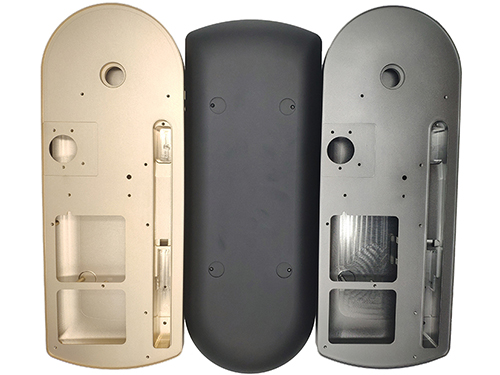

Experts in Precision Steel Machined Parts

Anebon’s steel machining specialists use cutting features unique to each steel alloy to precisely machine components. Customers have come to rely on three critical benefits of working with Anebon for custom-machined steel parts: We have state-of-the-art precision machines tha...Read more -

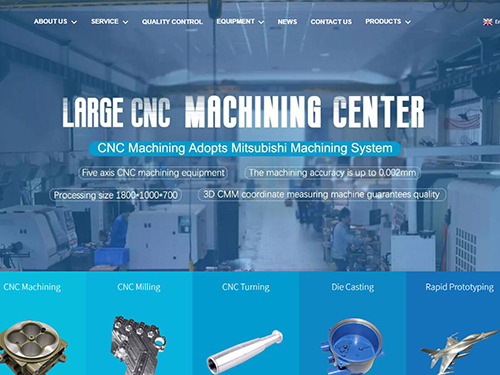

Anebon Launches New Responsive Website

Anebon invites new visitors and valued customers to explore our newly launched website, created with a visually appealing interface and simplified user experience. With advanced features like streamlined navigation and intuitive functionality, the new website provides visitors quick access to hel...Read more -

5 Axis Machining

As the name implies, five-axis machining (5 5-axis machining) is a CNC machine tool processing mode. The linear interpolation motion of any of the five X, Y, Z, A, B, and C coordinates is used. The machine tool used for five-axis machining is usually called a five-axis machine or a five-axis mac...Read more -

Our Rapid Development

Market conditions can have a huge impact. Market changes that occur during development can enable companies to return to the market when they are almost ready. Technology can have a similar effect. If technology changes while the product is being developed, it may be necessary to adapt and...Read more -

Thread milling pin Radial, arc, tangential approach, which is the most practical?

To achieve thread milling, the machine must have three-axis linkage. The helical interpolation is a function of CNC machine tools. The tool controls the tool to realize the helical trajectory. The helical interpolation is formed by the plane circular interpolation and the linear motion perpendicu...Read more