News

-

Simplify Part Design And Reduce Assembly Costs

One of the most underestimated costs in mass production is assembly. The time it takes to connect the parts manually. In some cases, manufacturers can automate the process. In other cases, this still requires labor. This is why many manufacturing industries occur in third world countries whe...Read more -

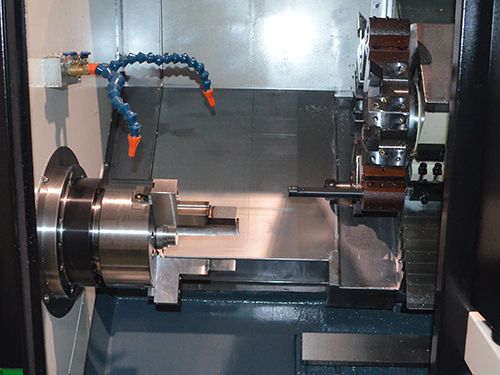

We are aware of safety precautions when using CNC lathes

1. First of all, before the non-standard parts are processed, we must do the preparatory work, carefully check whether your clothing meets the requirements of the work, and you must strictly observe it. cnc machining part 2. Check whether the equipment meets the normal working standards and whet...Read more -

Add Text On Parts

Depending on the manufacturing process and material used, text and lettering can be engraved, embossed, silkscreen printed, or rubbed on… the possibilities are manifold. machined part When adding text to a design for precision CNC machining, the first thing to consider is whether the text shoul...Read more -

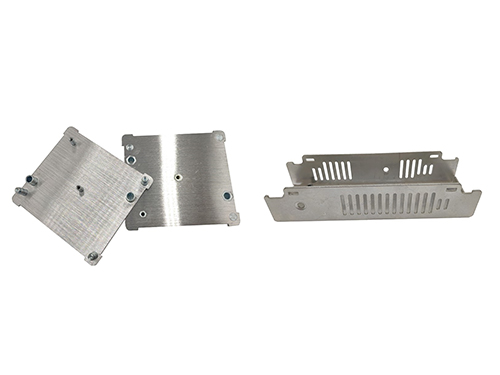

Non-standard future development direction

Non-standard parts processing refers to the parts processing in a country that does not set strict standard specifications and no parameters and is freely controlled by the enterprise. There are many types of non-standard parts. At present, there is no precise standard classification. The...Read more -

Small Parts, Great Effect

In mechanics, even small parts have many classifications and great functions. Although the parts are small, they have a great effect. Maybe the test results of the entire project will be delayed by a small size, or even fail. In modern society, the production of products is indispensable for the...Read more -

What We Did During The Epidemic

You have probably already heard from the news about the latest development of the coronavirus in Wuhan. The whole country is fighting against this battle, and as an individual business, we must also take all necessary measures to reduce our impact to a minimum. auto part Regarding our bu...Read more -

The Difference Between Multi-Slide and Progressive Die Stamping

Progressive die stamping Progressive die presses use vertical motion when processing slit coil metal. The bending and cutting operations are performed simultaneously in the mold to complete at least one part in each stroke of the machine. The coiled material is fed through a mold and processed st...Read more -

Happy New Year To All —— 2020

The Chinese New Year is coming, and Anebon wishes everyone good health and prosperity in the new year. Although the holidays are coming, we are still responsible for our products and services, we will never give up quality. In addition, Anebon hopes to work with you on more projects in 2020. cnc ...Read more -

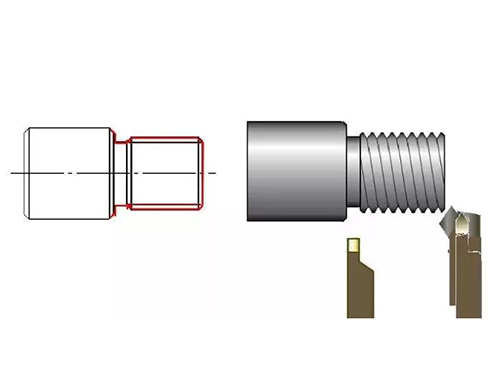

Thread turning to avoid disorderly buckling and binding

Common thread cutting methods Milling Thread Turning Thread Technological process Turning end face one turning thread major diameter (d < nominal diameter) one turning undercut (< thread minor diameter) → cha...Read more -

Visit Our Customer in Germany

We have worked with our customers for almost 2 years. The customer stated that our products and services are very good, so we invited us to visit his home (Munich), and he introduced us to many local habits and customs. Through this trip, we have more certainty about the importance of service and...Read more -

Customers from Europe visited Anebon

The purpose of Alex’s visit is to talk to us about improving the product. Jason personally went to the airport to pick him up to our company. After a formal visit to the company. Jason and Alex have a period of discussion.Finally we reached a consensus. Also Jason introduced him to many loc...Read more -

Customer From Germany Visit The Company For New Project

On May 15th, 2018, guests from Germany came to Anebon for a field trip. The company’s foreign trade department, Mr Jason Zeng warmly welcomed the guests. The purpose of this customer visit was to develop a new project, so Jason introduced the customer to the company and product information ...Read more