News

-

The Difference Between Non-standard Fasteners And Standard Fasteners

Non-standard fasteners refer to fasteners that do not need to correspond to the standard; that is, fasteners that do not have strict standard specifications can be freely controlled and matched. Usually, the customer puts forward specific requirements, and fastener manufacturers based on these d...Read more -

What Are The Applications of Stamping Parts In Automobiles

Stamping parts are processed in our daily lives, but we have never found out; in fact, most of the parts on the car are stamping parts; let’s take a closer look. The stamping parts on the car, we call it the automobile stamping parts, and there are many in the automobile. For example, the ...Read more -

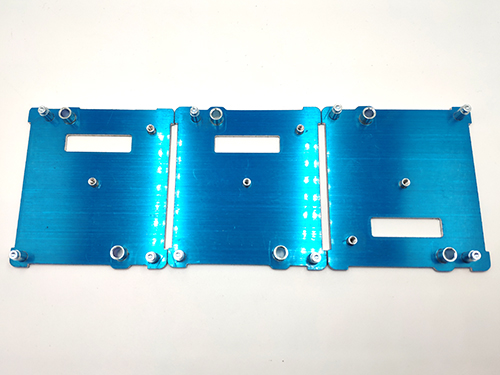

Anebon Works Together To Help The World During The New Coronavirus

The coronavirus crisis has turned everyone’s world upside down. As Anebon engaged in CNC machining, this is an opportunity to showcase himself. Respirators are urgently needed around the world to provide medical services to current patients. These lifesaving ventilators contain at l...Read more -

What Do You Need To Check For Stamping Parts Processing?

After the stamping parts are processed, we also need to inspect the processed parts and pass them to the user for inspection. So, what aspects do we need toexaminet when inspecting? Here is a brief introduction. 1. Chemical analysis, metallographic examination Analyze the content of chemical...Read more -

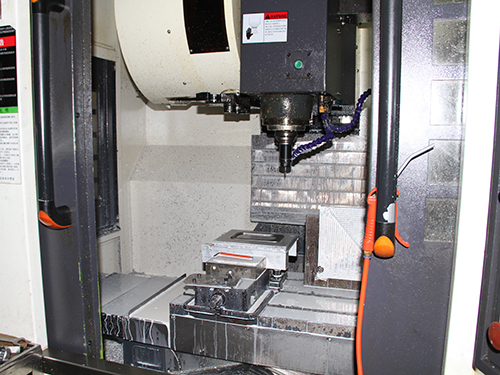

How should the milling cutter be selected under complex CNC machining conditions?

In machining, in order to maximize the processing quality and repeat accuracy, it is necessary to correctly select and determine the appropriate tool. For some challenging and difficult machining, the choice of tool is particularly important. 1. High-speed tool path 1. High-speed tool path The C...Read more -

Shell Molding And Die Casting

What is shell molding? Shell molding is a process involving the use of sand-based molds. The mold is a shell with thin walls made by applying a mixture of sand and resin to a pattern, which is a metal object made in the shape of a part. You can use this mode to create multiple shell molds. cnc ...Read more -

Use of Basic Measurement Tools

1. Application of calipers The caliper can measure the inner diameter, outer diameter, length, width, thickness, step difference, height, and depth of the object; the caliper is the most commonly used and most convenient and frequently used measuring tool at the processing site. Digital Caliper: ...Read more -

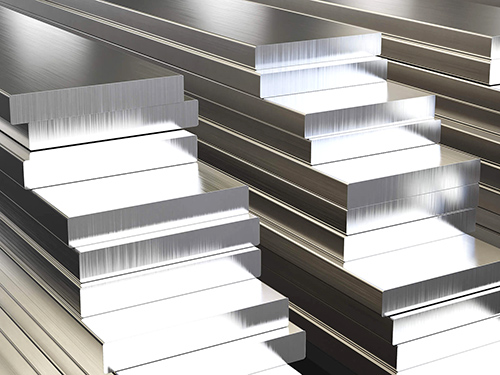

Why Most of The Materials We Process Are Aluminum?

Aluminium is the second most plentiful metallic element on earth. Aluminum is the second most widely used metallic material after steel in its pure or alloyed form. Among the most striking characteristics of aluminum is its versatility. The range of physical and mechanical properties that can be ...Read more -

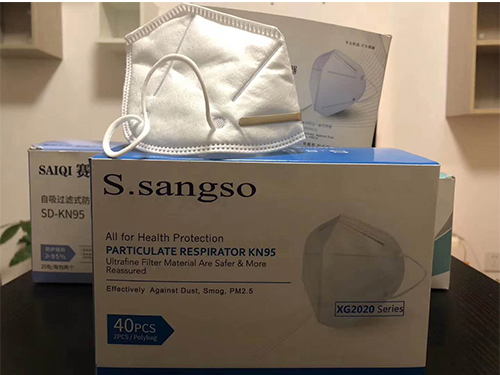

Carried Out Infrared Thermometers And Masks — Anebon

Due to the epidemic situation and according to the needs of customers, our company has carried out related business of related infrared thermometers and masks. Infrared thermometer, masks KN95, N95 and disposable masks, we have cheap prices and guarantee high quality. We also have FDA and CE cert...Read more -

CNC Collet Chucks

The most obvious advantage when machining parts in the 0 to 3-inch range is the additional tool clearance provided by a collet chuck’s streamlined shape and reduced nose diameter. This arrangement makes machining much closer to the chuck, providing maximum rigidity and better surface finishes. In...Read more -

6 CNC Industry Knowledge

1. The number “7″ is highly unseen in the machinery industry. For example, you can hardly buy M7 screws on the market, and 7mm shafts and bearings are not standard. CNC machining part 2. “One millimeter” is a relatively large scale in the CNC industry, even in the entire ...Read more -

7 Reasons Why Titanium Is Difficult To Process

Content Menu ● 1. Low Thermal Conductivity ● 2. High Strength and Hardness ● 3. Elastic Deformation ● 4. Chemical Reactivity ● 5. Tool Adhesion ● 6. Machining Forces ● 7. Cost of Specialized Equipment ● Frequently Asked Questions Titanium, known for its exceptional strength-to-weight rati...Read more