News

-

The chief technical engineer has many years of experience and 6 suggestions for controlling product quality!

“Product quality is everyone’s responsibility”; high-quality products are produced, managed, and controlled, not tested. “Product quality control is a headache for every enterprise.” quality control is a systematic project with its own laws and unique control method...Read more -

CNC programming engineer factory technical specification

1. Clarify the programmer’s responsibilities and control processing quality, processing efficiency, cost control, and error rate in the mold CNC manufacturing process. 2. When the programmer receives a new mold, he must understand the mold’s requirements, the structure’s ra...Read more -

Is it necessary to warm up the CNC machine every morning when it is turned on?

The factory uses precision CNC machine tools (machining center, EDM, slow wire walking, and other machine tools) for high-precision machining. Do you have such experience:start-upp for processing every morning, the machining accuracy of the first piece is often not good enough; The accuracy of th...Read more -

Summary of eight processing methods of thread, you must know when doing machining

A summary of eight processing methods of thread you must know when machining. .The English word corresponding to Screw is Screw. The meaning of this word has changed a lot in recent hundreds of years. At least in 1725, it means “mating”.The application of the thread principle can be t...Read more -

Metal surface treatment, ten methods, see how many you know?

Surface treatment is to form a surface layer with one or more particular properties on the material’s surface by physical or chemical methods. Surface treatment can improve product appearance, texture, function, and other aspects of performance. 1. Anodizing It is mainly the anodic oxi...Read more -

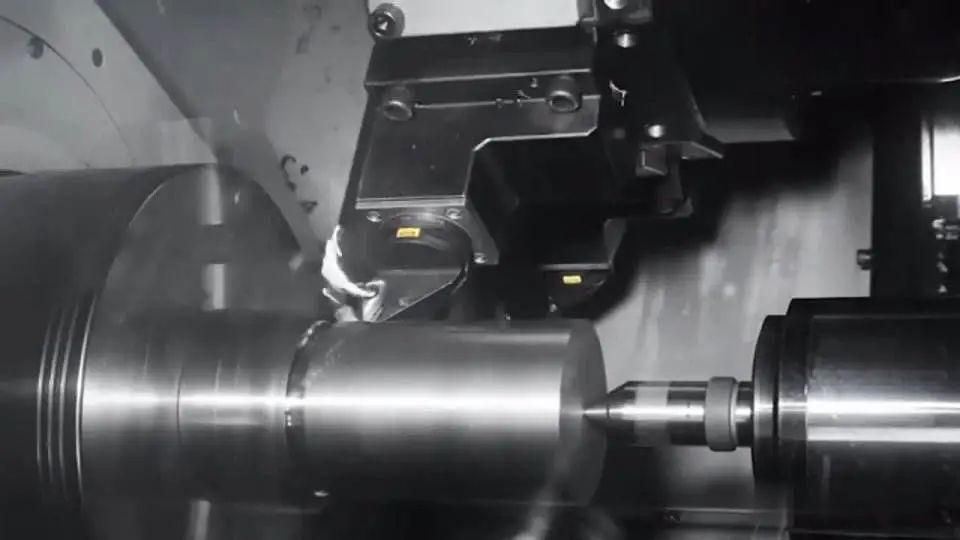

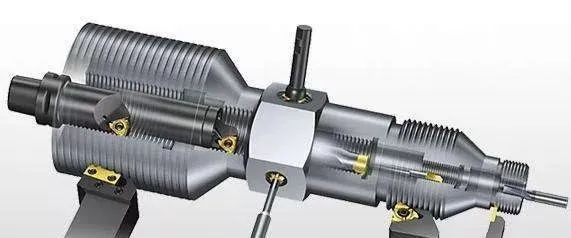

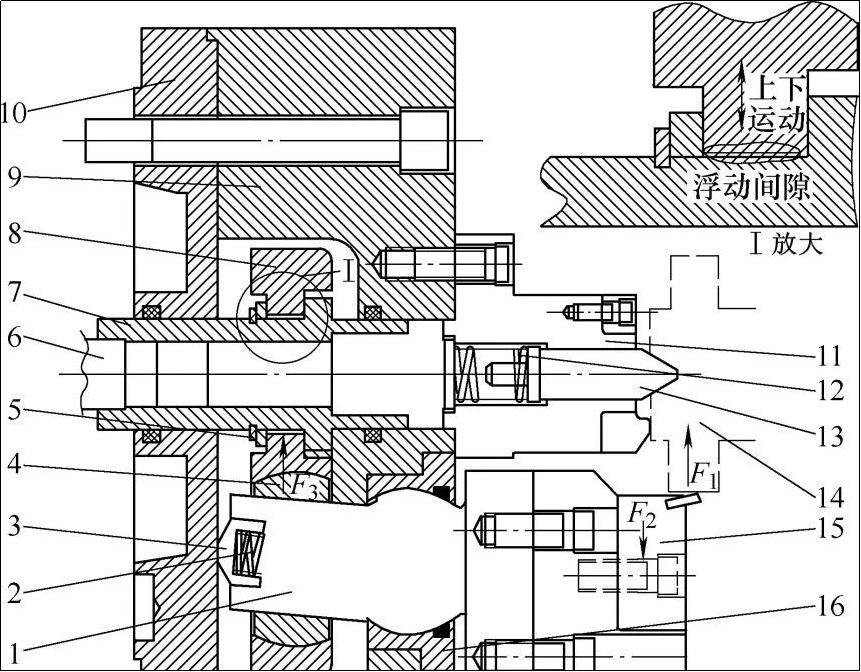

Selection and Maintenance of Machine Tool Chucks in the Machining of Engine Shaft Parts

For engines, shaft components such as crankshafts, camshafts, and cylinder liners use chucks in each processing process. During processing, the chucks center, clamp and drive the workpiece. According to the ability of the chuck to hold the workpiece and maintain the center, it is divided into rig...Read more -

Machining center programming skills, sharing from CNC technicians!

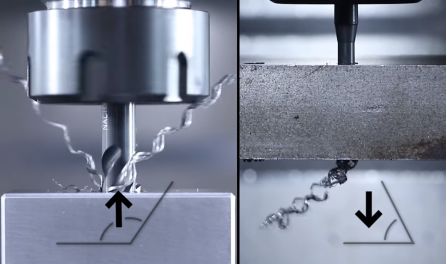

We usually have three options for drilling cycle selection: 1. G73 (Chip breaking cycle) Usually used for machining holes more than 3 times the diameter of the bit but not more than the effective edge length of the bit 2. G81 (shallow hole circulation) It is usually used for drilling center holes...Read more -

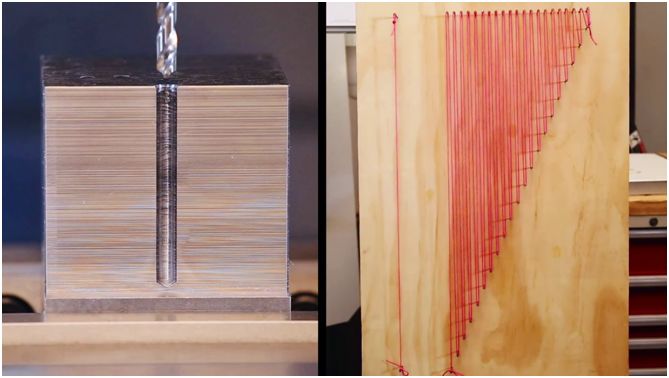

How to choose the appropriate drilling cycle?

We usually have three options for drilling cycle selection: 1. G73 (Chip breaking cycle) Usually used for machining holes more than 3 times the diameter of the bit, but not more than the effective edge length of the bit 2. G81 (shallow hole circulation) It is usually used for drilling center hole...Read more -

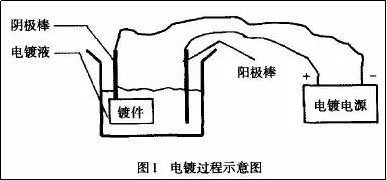

What is the difference between chrome plating, nickel plating and zinc plating?

First, let’s understand what is electroplating.Electroplating uses the principle of electrolysis to coat a thin layer of other metals or alloys on the surface of certain metals. Such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper ...Read more -

A small tap can contain so much information. . .

Tap chipping Tapping is a relatively tricky machining process because its cutting edge is basically in 100% contact with the workpiece, so various problems that may arise should be considered in advance, such as the performance of the workpiece, the selection of tools and machine tools, and the ...Read more -

Another “lighthouse factory” in China! ! !

In 2021, the World Economic Forum (WEF) officially released a new list of “lighthouse factories” in the global manufacturing sector. Sany Heavy Industry’s Beijing pile machine factory was successfully selected, becoming the first certified “lighthouse factory” in the...Read more -

Precautions when the machine tool is shut down for a long time

Good maintenance can keep the machining accuracy of the machine tool in the best state, prolong the service life, and adopt the correct startup and debugging method for the CNC machine tool. In the face of new challenges, it can show a good working state and improve production efficiency and proc...Read more