News

-

The highest machining accuracy that can be achieved by turning, milling, planing, grinding, drilling and boring

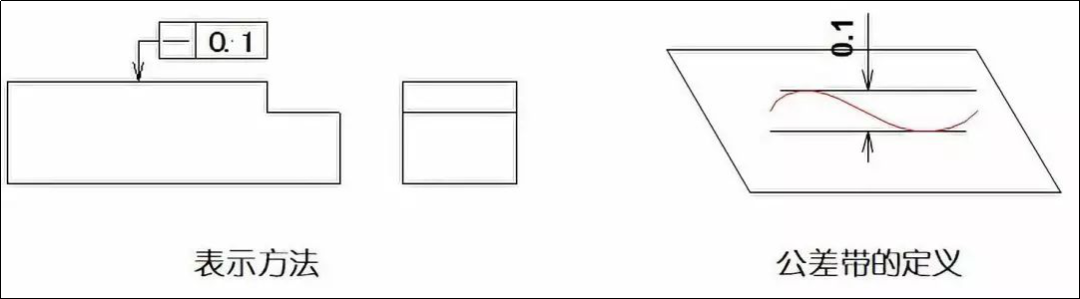

The machining precision is mainly used to characterize the fineness of products, such as CNC turning parts and CNC milling parts, and is a term used to evaluate the geometric parameters of machined surfaces. Machining accuracy is measured by tolerance grade. The smaller the grade value, the highe...Read more -

Common Sense of Selection and Use of Fixtures for CNC Machine Tools

Mechanical processing can be divided into two categories according to the production batch: single piece, multiple varieties, and small batch (referred to as small batch production). The other is small variety and large batch production. The former accounts for 70~80% of the total output value ...Read more -

What is the maximum machining accuracy of the machine tool?

Turning, milling, planing, grinding, drilling, boring, the highest accuracy of these machine tools and the tolerance levels that various processing methods can achieve are all here. TurningThe cutting process in which the workpiece rotates and the turning tool moves in a straight line or curve i...Read more -

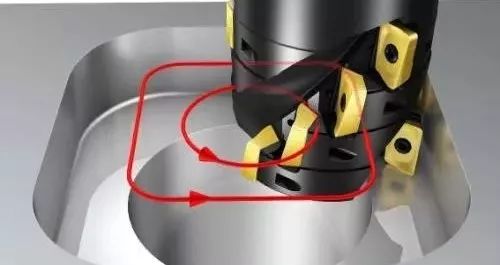

Cutting skills, NC machining skills

When we operate CNC machine tools to process CNC Machining parts, we often use the following tool walking skills: 1. The speed of white steel knife shall not be too fast.2. The copper workers should use less white steel knives for rough cutting and more flying knives or alloy knives.3. If the wor...Read more -

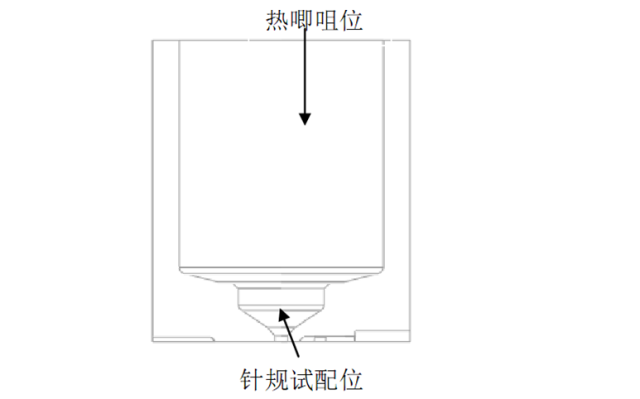

Positioning and clamping of machining

This is the summary of the people in the industry when summarizing the fixture design, but it is far from simple. In the process of contacting various schemes, we found that there are always some positioning and clamping problems in the preliminary design. In this way, any innovative scheme will ...Read more -

Knowledge of super stainless steel

Stainless steel of CNC Machining Parts is one of the most common steel materials in instrument work. Understanding stainless steel knowledge will help instrument operators better master instrument selection and use.Stainless Steel is the abbreviation of stainless steel and acid resistant steel. T...Read more -

What do 4.4 and 8.8 on threaded bolts mean?

The performance grade of bolts used for steel structure connection is 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9 and so on. Bolts of grade 8.8 and above are made of low carbon alloy steel or medium carbon steel and heat-treated (quenched, tempered), which are generally called high strength bol...Read more -

Hole processing knowledge, very comprehensive, a must-read for robots

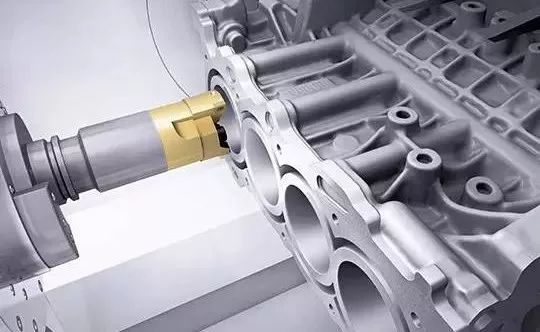

Compared with external surface processing, the conditions of hole processing are much worse, and it is more difficult to process holes than to process external circles. This is because: 1) The size of the tool used for hole machining is limited by the size of the hole to be machined, and the rigi...Read more -

Machining center knowledge

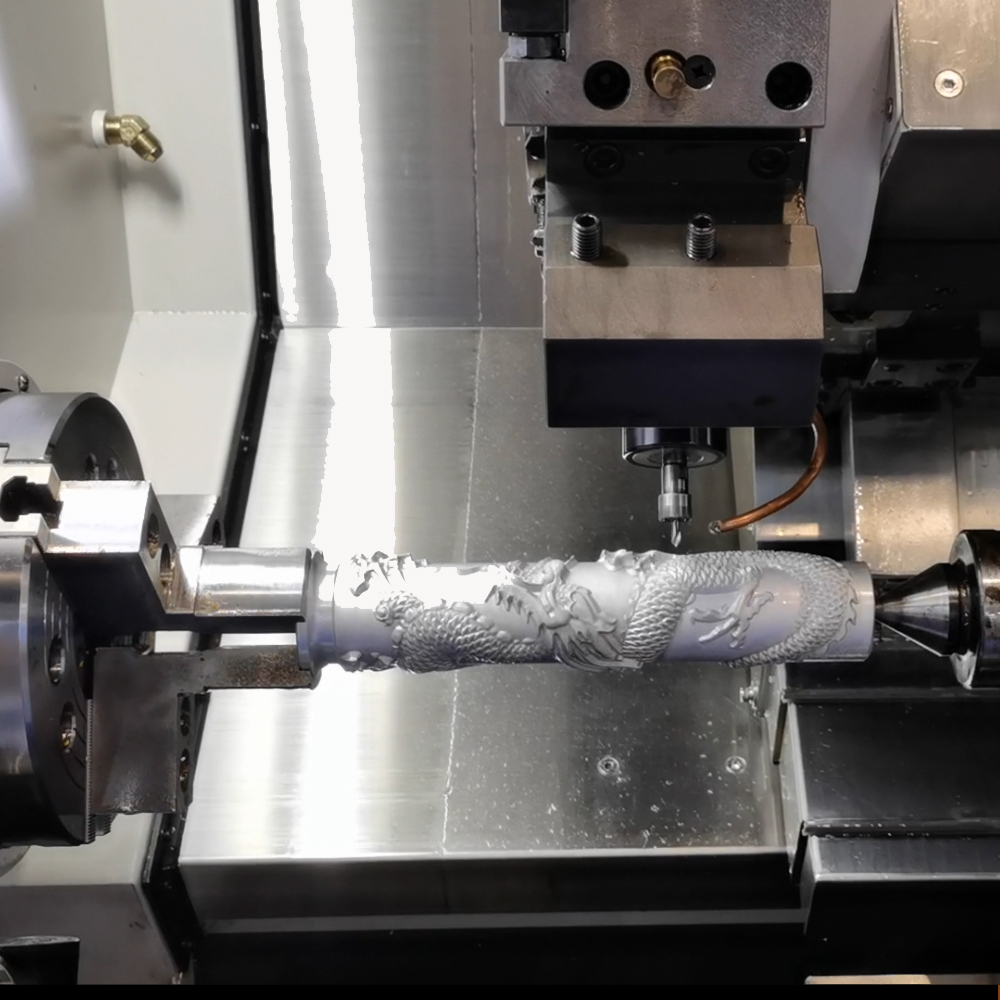

The machining center integrates oil, gas, electricity, and numerical control, and can realize one-time clamping of various complex parts such as discs, plates, shells, cams, molds, etc., and can complete drilling, milling, boring, expanding, reaming, Rigid tapping and other processes are processe...Read more -

The machine has been working for a lifetime, what does the 4.4 and 8.8 on the bolt mean?

The performance grades of bolts for steel structure connection are divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. Among them, the bolts of grade 8.8 and above are made of low-carbon alloy steel or medium-carbon steel and are heat-treated (quenching, t...Read more -

Process measures and operation skills to reduce deformation of aluminum parts

There are many reasons for the deformation of aluminum parts, which are related to the material, shape of the part, and production conditions. There are mainly the following aspects: deformation caused by internal stress of blank, deformation caused by cutting force and cutting heat, and deformat...Read more -

One article to understand drilling, reaming, boring, pulling… A must read for machinery industry worker!

Drilling, pulling, reaming, boring… What do they mean? The following will teach you to easily understand the difference between these concepts. Compared with external surface processing, the conditions of hole processing are much worse, and it is more difficult to process holes than to proc...Read more