I. Installation of numerical control milling machine:

A general numerical control milling machine is designed with mechanical and electrical integration. It is shipped as a complete machine without disassembly and packaging from the manufacturer to the user. Therefore, after receiving the machine tool, the user only needs to follow the instructions. Pay attention to the following aspects:

(1) unpacking: after unpacking the machine tool, first find the accompanying technical documents according to the packing marks and count the accessories, tools, spare parts, etc., according to the packing list in the technical documents. If the material in the box is inconsistent with the packing list, contact the manufacturer as soon as possible. Then, please read the instructions carefully and do the installation according to them.

(2) hoisting: according to the hoisting drawing in the instruction manual, pad wood block or thick cloth at the appropriate position to prevent the steel wire rope from damaging the paint and processing surface. In the process of lifting, the center of gravity of the machine tool should be minimized. If the electric tortoise of the CNC machine tool is separated, there is a lifting ring on the top of the electric cabinet for lifting.

(3) Adjustment: the main machine is shipped as a complete machine for the CNC milling machine, which is adjusted before delivery. During installation, the user should pay attention to the adjustment of oil pressure, the adjustment of automatic lubrication, and the critical inspection to prevent the vertical sliding device of the lifting platform from functioning.

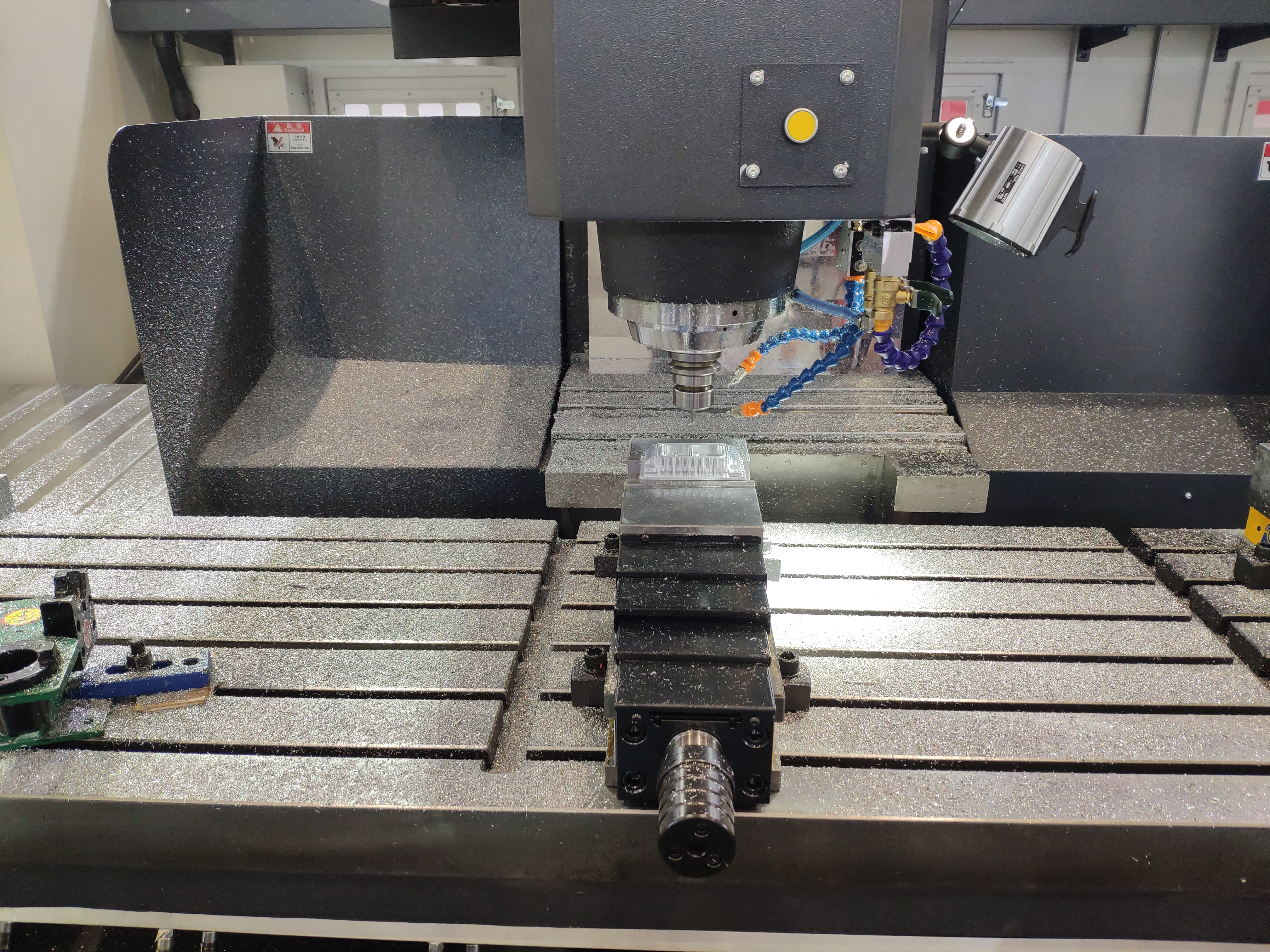

II. Debugging and acceptance of CNC milling machine:

The main machine is shipped as a complete machine for the general CNC milling machine, which was adjusted before delivery. However, users still need to pay attention to the following points before using: debugging a CNC milling machine:

(1) adjustment of oil pressure: because appropriate pressure is required for hydraulic speed change, hydraulic tension, and other mechanisms after the machine tool is unpacked, remove the oil seal for rust pprevention that is, fill the oil pool with oil, start the oil pump to adjust the oil pressure, generally at 1-2pa. turned part

(2) adjustment of automatic lubrication: most CNC milling machines use automatic timing and quantitative lubrication stations for oil supply. Before start-up, check whether the lubricating oil pump starts according to the specified time. Relays usually make these time adjustments. It is essential to check whether the vertical sliding device of the lifting platform is effective. The inspection method is straightforward. When the machine tool is powered on, fix the meter base on the bed, point the dial indicator probe to the worktable, then cut off the power of the worktable suddenly, and observe whether the worktable sinks through the dial indicator, with the change of 0. 01 - 0. 02mm is allowed, too much sliding will affect the consistency of parts processed in batches. At this time, the self-locking device can be adjusted.

(3) acceptance of CNC milling machine: the acceptance of CNC milling machines is mainly based on the professional standards issued by the state. There are two kinds of zbj54014-88 and zbnj54015-88. Before leaving the factory, the manufacturer inspected the machine tool according to the above two standards, and the quality inspection department issued the product qualification manual. The user can conduct sampling inspections or all re-inspections of the accuracy according to the items in the qualification manual, and the unit masters the actual testing means. The user can negotiate with the manufacturer if there are any unqualified items. If the re-inspection data meets the requirements of the factory certificate, it can be recorded into the file for future reference. CNC machining part

| Stainless Steel Part | Plastic Cnc | Lathe Turning Services |

| Metal Machining Parts | Precision Parts Manufacturing | What Is CNC Turning |

| CNC Machining Prototype | Quality Chinese Products | Aluminium Turning |

www.anebon.com

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Post time: Nov-02-2019