The thread is mainly divided into connecting thread and transmission thread

For the connecting threads of CNC Machining parts and CNC Turning parts, the main processing methods are: tapping, threading, turning, rolling, rolling, etc. For the transmission thread, the main processing methods are: rough and fine turning---grinding, whirlwind milling---rough and fine turning, etc.

The various processing methods are described below:

1. Thread cutting

Generally refers to the method of processing threads on cnc turning parts with forming tools or grinding tools, mainly including turning, milling, tapping, threading, grinding, grinding and whirlwind cutting. When turning, milling and grinding threads, the transmission chain of the machine tool ensures that the turning tool, milling cutter or grinding wheel moves a lead accurately and evenly along the axis of the workpiece every time the workpiece rotates. When tapping or threading, the tool (tap or die) and the workpiece make relative rotational movement, and the first formed thread groove guides the tool (or workpiece) to move axially.

Thread turning on a lathe can use a form turning tool or a thread comb (see threading tools). Turning threads with forming turning tools is a common method for single-piece and small-batch production of threaded workpieces due to the simple tool structure; turning threads with thread cutters has high production efficiency, but the tool structure is complex and is only suitable for turning in medium and large-scale production Short threaded workpieces with fine pitch. The pitch accuracy of trapezoidal thread turning on ordinary lathes can only reach grades 8 to 9 (JB2886-81, the same below); processing threads on specialized thread lathes can significantly improve productivity or accuracy.

2. Thread milling

Milling is performed on a thread milling machine with a disc cutter or a comb cutter. Disc milling cutters are mainly used for milling trapezoidal external threads on workpieces such as screw rods and worms. The comb-shaped milling cutter is used for milling internal and external ordinary threads and taper threads. Since it is milled with a multi-edged milling cutter, the length of its working part is greater than the length of the processed thread, so the workpiece only needs to rotate 1.25 to 1.5 turns to process. Complete, high productivity. The pitch accuracy of thread milling can generally reach grade 8-9, and the surface roughness is R 5-0.63 microns. This method is suitable for batch production of threaded workpieces with general precision or rough machining before grinding.

3. Thread grinding

It is mainly used for machining precision threads of hardened workpieces on thread grinders. According to the shape of the cross-section of the grinding wheel, it can be divided into two types: single-line grinding wheel and multi-line grinding wheel. The pitch accuracy of the single-line grinding wheel is 5-6 grades, the surface roughness is R 1.25-0.08 microns, and the dressing of the grinding wheel is more convenient. This method is suitable for grinding precision lead screws, thread gauges, worms, small batches of threaded workpieces and relief grinding precision hobs. Multi-line grinding wheel grinding is divided into two types: longitudinal grinding method and plunge grinding method. In the longitudinal grinding method, the width of the grinding wheel is smaller than the length of the thread to be ground, and the thread can be ground to the final size by moving the grinding wheel longitudinally once or several times. In the plunge grinding method, the width of the grinding wheel is greater than the length of the thread to be ground, and the grinding wheel cuts into the surface of the workpiece radially, and the workpiece can be ground after about 1.25 revolutions. The productivity is high, but the precision is slightly lower, and the dressing of the grinding wheel is more complicated. The plunge grinding method is suitable for relief grinding taps with large batches and grinding some threads for fastening.

4. Thread grinding

A nut-type or screw-type thread grinder is made of softer materials such as cast iron, and the parts of the processed threads with pitch errors are ground in forward and reverse directions to improve the pitch accuracy. The hardened internal thread is usually also eliminated by grinding to improve accuracy.

5. Tapping and threading

Tapping is to use a certain torque to screw the tap into the pre-drilled bottom hole on the workpiece to process the internal thread. Threading is the use of dies to cut external threads on bar (or pipe) workpieces. The machining accuracy of tapping or threading depends on the accuracy of the tap or die. Although there are many ways to process internal and external threads, small-diameter internal threads can only be processed by taps. Tapping and threading can be done manually, or lathes, drilling machines, tapping machines and threading machines.

The principle of thread turning cutting quantity selection

Since the pitch (or lead) of the thread is specified by the pattern, the key to selecting the cutting amount when turning the thread is to determine the spindle speed n and the cutting depth ap.

1. Selection of spindle speed

According to the mechanism that the spindle rotates 1 revolution and the tool feeds 1 lead when turning the thread, the feed speed of the CNC lathe when turning the thread is determined by the selected spindle speed. The thread lead commanded in the thread processing block (the thread pitch is the single-start thread), which is equivalent to the feed rate vf represented by the feed amount f (mm/r)

vf = n f (1)

It can be seen from the formula that the feed rate vf is proportional to the feed rate f. If the spindle speed of the machine tool is selected too high, the converted feed rate must greatly exceed the rated feed rate of the machine tool. Therefore, when selecting the spindle speed for thread turning, the parameter setting of the feed system and the electrical configuration of the machine tool should be considered to avoid the phenomenon of "chaotic teeth" of the thread or the pitch near the start/end point not meeting the requirements.

In addition, it is worth noting that once the thread processing is started, the spindle speed value generally cannot be changed, and the spindle speed including finishing machining must follow the selected value at the first feed. Otherwise, the CNC system will cause the thread to be "chaotic" due to the "overshoot" amount of the pulse encoder reference pulse signal.

2) Selection of depth of cut

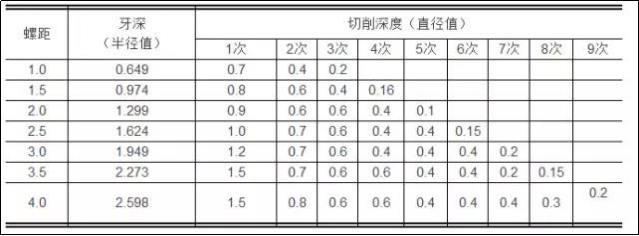

Since the thread turning process is forming turning, the tool strength is poor, and the cutting feed is large, and the cutting force on the tool is also large. Therefore, fractional feed processing is generally required, and a relatively reasonable cutting depth is selected according to the decreasing trend. Table 1 lists the reference values of feed times and depth of cut for common metric thread cutting for readers' reference.

Table 1 Feed times and depth of cut for common metric thread cutting

Post time: Dec-10-2022