What are the basic abilities that a qualified mechanical designer should possess?

To be a good mechanical designer, you need to have a bunch of skills, like:

1. Being really good at using CAD software and other design tools

2. Knowing a lot about engineering principles

3. Being able to make really detailed drawings and specifications

4. Understanding materials and how things are made

5. Being great at solving problems and thinking really carefully

6. Being a good communicator and teammate

7. Paying close attention to all the little details and being accurate

8. Being able to work within deadlines and limits

9. Knowing all the rules and standards for the industry

10. Always learning new stuff and being flexible about using new technology and methods.

The path to advancement as a mechanical engineer:

Baby grade

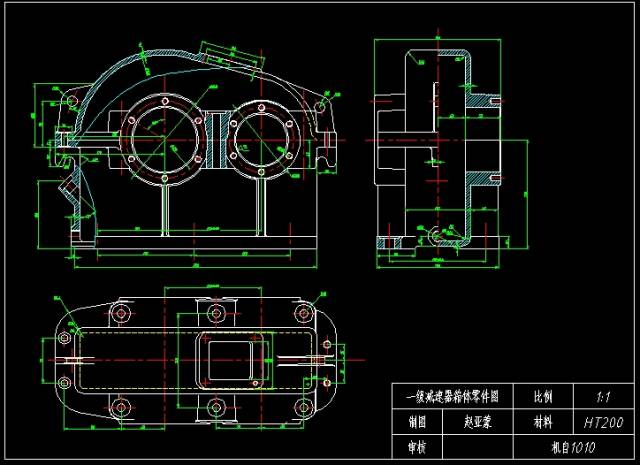

At this level, it’s all about becoming a master in using the tools necessary for design work. This means being really good at operating CAD, ProE, SW, ANSYS, Mathcad, and other similar software. You also need to have a thorough understanding of basic theories such as material mechanics, engineering mechanics, mechanical design theory, machining technology, and metal technology, as well as being proficient in essential knowledge like tolerances and engineering materials.

When it comes to being skilled, it’s not just about claiming to be good at something – it’s about really knowing your stuff. For example, saying you’re proficient in a software means you should have done a lot of work with it, like drawing thousands of three-dimensional models, not just a few drawings.

It’s important to avoid just claiming proficiency without truly understanding how to use the software effectively. Simply claiming to be proficient without demonstrating extensive experience can make your proficiency hard to define. If we have to put a number on it, drawing thousands of three-dimensional models is a good measure of true proficiency, rather than just being able to create a few engineering drawings.

A deep understanding of mechanical theory

A strong grasp of mechanical theory is essential, not just knowing the basics but being able to thoroughly understand and apply them.Being skilled in relevant knowledge is also important. For instance, being proficient in tolerance coordination involves memorizing key concepts such as the datum system, shape tolerance, positional tolerance, and extended tolerance zone.

Proficient in relevant knowledge

Additionally, knowing how to apply these tolerances, detect them, and ensure they are maintained during processing is crucial. Having a basic understanding of technology is also necessary. Once these requirements are met, you will have a solid foundation in mechanical design.

Kindergarten level

Drawings are the language of engineers, and children should learn to speak them.

The national standard is grammar

You should commit the 30 to 50 commonly used national cartography standards to memory. If there are specific company standards and requirements, you’ll need to know those too. They may seem overwhelming, but with practice – after creating a couple of thousand engineering drawings – you’ll find that following these standards becomes second nature. I’ve mentioned this before, but it’s surprising how many experienced mechanical designers struggle to produce quality drawings.

The Grammar of Three-Dimensional Figures

When creating three-dimensional drawings, it’s important to consider the structure and organization, similar to grammar in language. Simply drawing based on dimensions isn’t enough. Factors like where to start from and the order of drawing parts must align with the manufacturing process. Decisions about reference points and features are also crucial and must be carefully considered. The assembly of the drawings should follow a step-by-step process based on assembly specifications.

Children’s level

The children’s level is the longest stage. At this stage, simple parts design can be completed under the guidance of the master.

When we’re designing something, we need to really understand how it’s supposed to work and what it’s made of. We also need to do some calculations to make sure it’s all going to work correctly. It’s not enough to just rely on computer programs to figure it out for us. We need to use our own smarts and creativity to design something that works well, is easy to make, and doesn’t cost too much.

At the end of the day, it’s all about getting the job done without spending too much money.

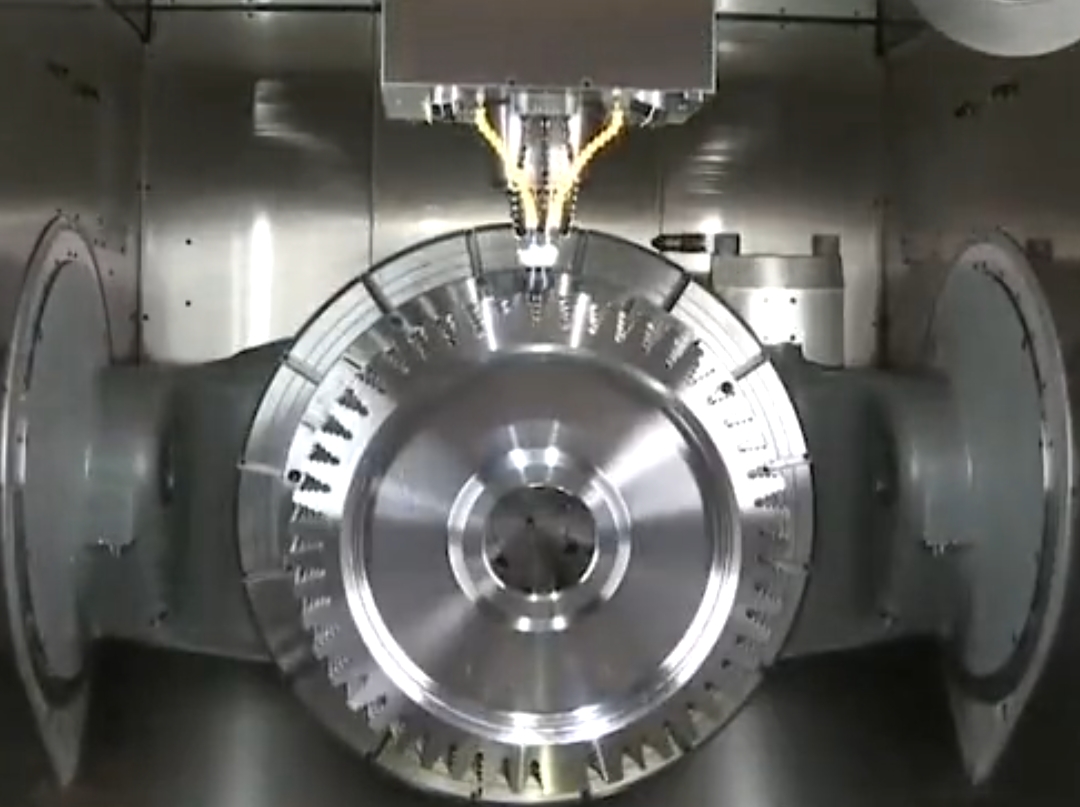

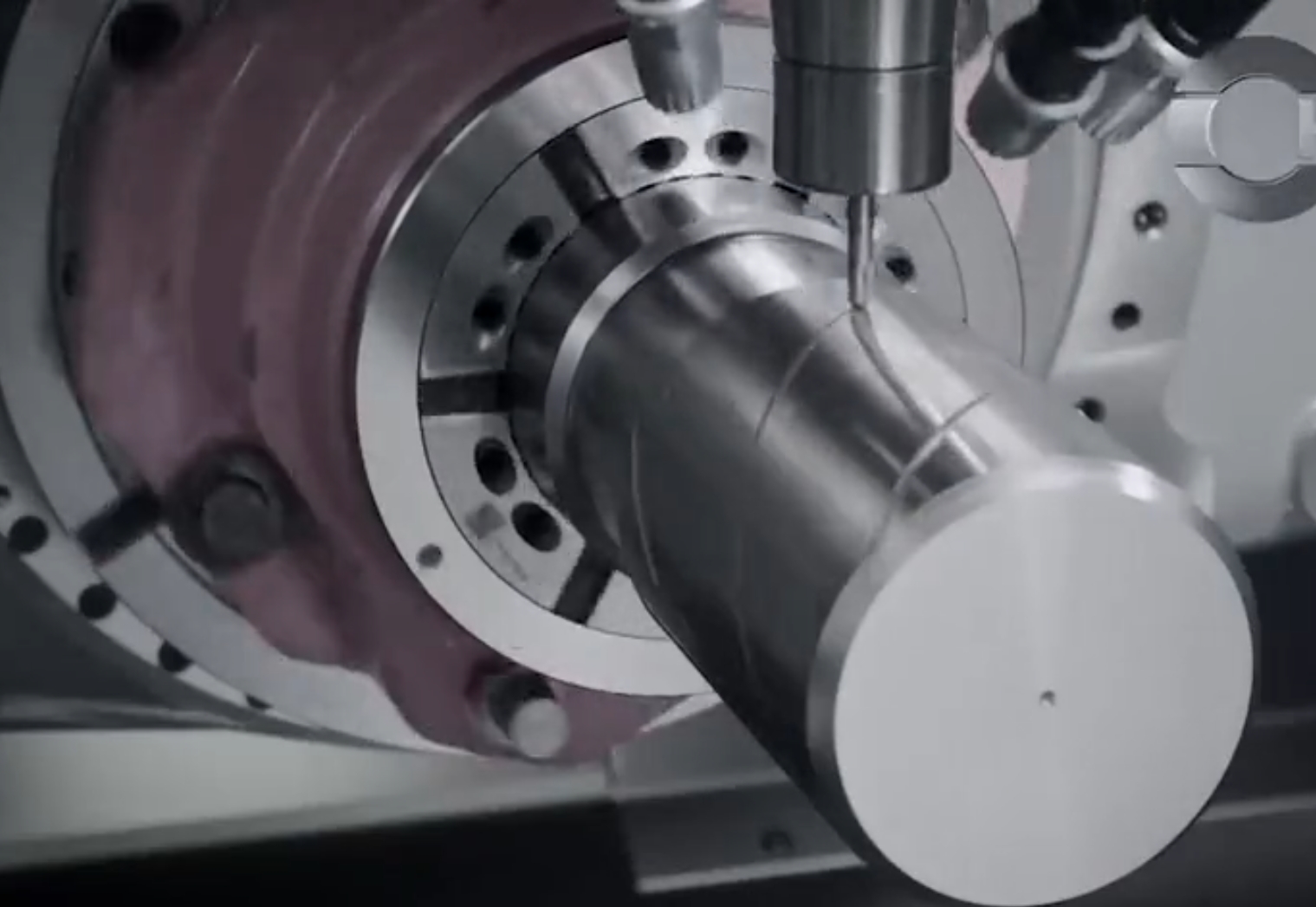

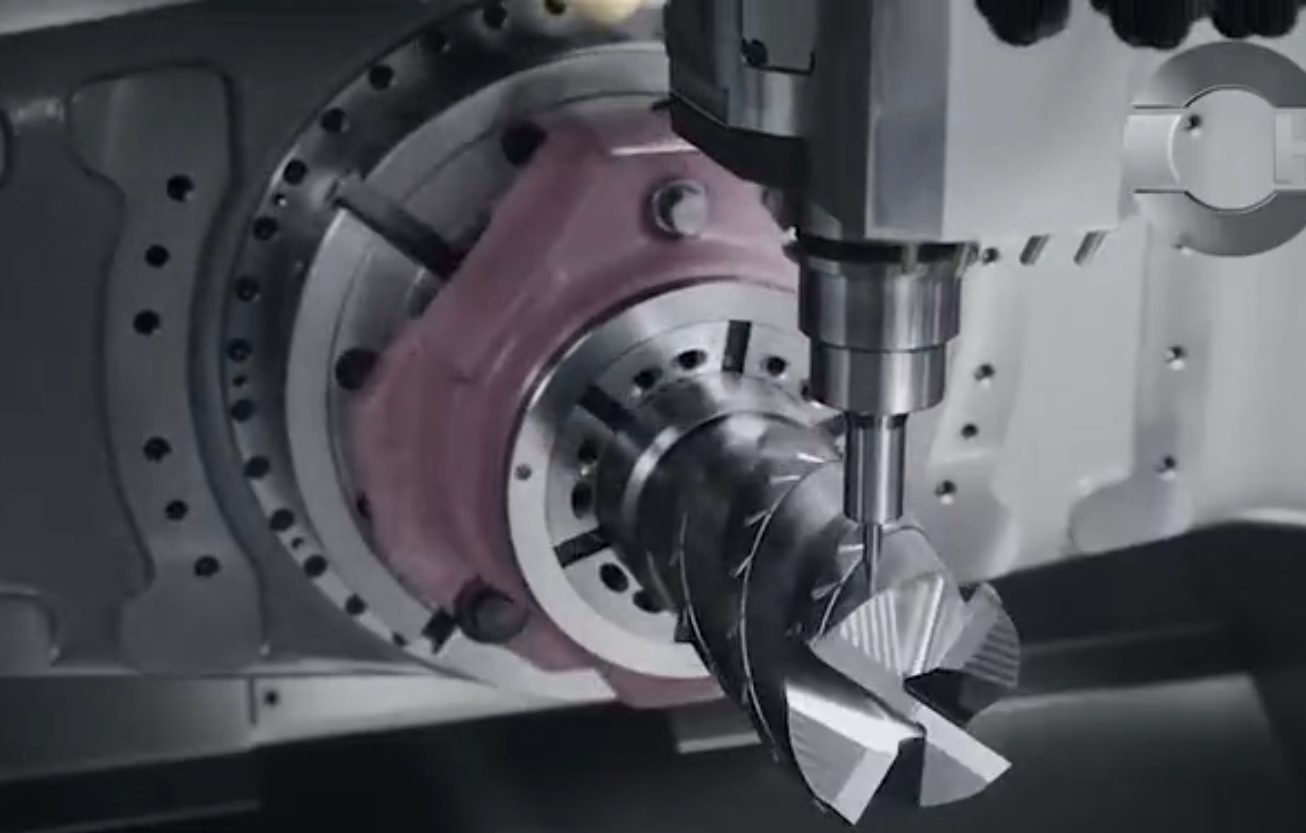

The craftsmanship aspect

At this point, you need to have a good understanding of how each part you design will be made, what machines will be used, how the surfaces will be treated, and the importance of each level of accuracy. This is the best way to make sure that the parts you design can actually be made with today’s technology and methods.

Assembly issues

Next, think about how the parts and machines you design will be put together. Consider what tools will be needed for assembly, whether special lifting holes are required, and how the parts will need to be positioned. Also, consider how easy it will be to fix, use, and replace parts when they wear out.

It’s important to recognize that understanding how things are actually made is more valuable than just having theoretical knowledge. With real-world experience, you’ll see that simply creating 3D animations and colorful visualizations doesn’t necessarily make someone a skilled professional.

You have a chance to be scolded.

After completing this stage, I realized that I could now design basic structures as a designer. I also began to understand that mistakes made during the design process can lead to issues during production, sourcing, use, maintenance, and transportation. It’s important to address these potential errors during the design phase to prevent problems later on.

The workshop workers will scold you.

Here are the reasons: a specific part you designed will need 20 tools replaced in the manufacturing process; due to tight tolerance requirements, the processing success rate for the part is just 50%; the part needs to be repositioned multiple times during processing, adding complexity to the production process. Additionally, special tooling is required for processing the precision metal parts, as the quality inspector needs to use three-dimensional coordinates for inspection.When it comes to design, simplicity is key. It’s often said that after completing a part design, designers should consider if the tolerance accuracy can be reduced and if the structure can be made simpler.

Product users will criticize

Operators play a crucial role in identifying and solving problems, so your design should prioritize user-friendly features. For instance, complicated equipment or excessively long instruction manuals can make it challenging for operators to use the product effectively.

Misoperation is often the result of design errors, such as creating identical buttons that are easily pressed incorrectly.

Comfort is also important to consider. Understanding the optimal height and force required for hand operation can help prevent misoperation and reduce physical strain on operators.

Using accurate measurements and understanding human needs is crucial for designing user-friendly mechanical parts.

For example, when designing control handles, it’s important to calculate the most comfortable height and required force for users. This ensures that the handle is ergonomic and easy to use. Additionally, considering the shape and size of the handle can further enhance comfort and usability.

Even if these technical aspects are addressed, customers may still find the design uncomfortable. Designers need to consider psychological and aesthetic factors to create products that are not only functional but also appealing and comfortable.

In practical terms, this means understanding human memory limitations when displaying information, creating designs that appear strong and reliable, and ensuring that products are approachable and inviting to users. Psychology and aesthetic considerations play a crucial role in addressing these aspects of design.

The operation and maintenance personnel will scold you.

When designing a product, it’s essential to consider the packaging method, transportation requirements, and dimensions for road transport, as well as the need for export and container considerations. These are just a few of the many logistical issues that must be addressed.

Designing a product for easy maintenance is also crucial. The aim is to make maintenance and repair tasks as simple as possible, ensuring that individuals with varying levels of expertise can handle them. When products are overly complicated to maintain, it indicates a failure in the design process.

To thrive as a designer, it’s important to embrace a lifelong learning mindset, as the field presents continuous challenges. Instead of dwelling on criticism or doubts about one’s skills, focus on continually improving and refining your craft.

Junior level

The kids’ level is finally done, and it’s on to the teen stage. I feel pretty confident and a bit flashy at this point. I don’t overthink things and tend to take my skills for granted.

At this stage, it’s all about being passionate about our products and the industry itself.

Each product is like a designer’s baby. As the saying goes, “you get what you pay for,” and if you spend a lot, you’ll love it even more.

Ideological aspects

I’ve poured so much energy into mechanical design, pulling all-nighters to perfect a product and even waking up in a panic over a design error. I’ve meticulously scrutinized every detail, right down to selecting specific bolts, and invested countless nights studying various subjects. My best years have been devoted to machinery, so it’s no wonder I’m a bit cocky. It’s the essence of confidence.

Skills aspects

At this point, we understand how to process each part and the different methods available for this. We also know how many times each process needs to be loaded on the machine tool, the machine tool accessories required, and the specific cutting tool specifications.

Let’s use threads as an example. We’ll cover the tools needed for turning internal and external threads, the different types of thread cutters, the methods for feeding thread cutters, and how to work with trapezoidal, zigzag, and rectangular threads.

Coordinate the needs of all parties

To sum it up, the designer is typically blamed for any mistakes.

Mechanical designers don’t have a lot of resources.

Creating quality products is a challenging job.

Manufacturers aim to cut costs, while sellers want products that appeal to buyers.

Customers focus on price, appearance, and brand. Front-line users prioritize product features and how they work.

After-sales maintenance staff worry about how easy it is to take apart, check, and fix products.

Mechanical Designer’s Notes

1. Drawing is a fundamental aspect of a designer’s work.

Through a drawing, you can gauge an engineer’s proficiency, a designer’s attention to detail and adherence to industry standards, and their knowledge of manufacturing processes.

Drawing is a blend of precision and creativity. The standards and analysis are ultimately aimed at achieving aesthetic appeal, which is a key requirement for drawing. Developing this skill takes time and practice. It’s only after creating numerous drawings that a designer can appreciate the beauty inherent in their work.

2. The design and application of threads can show the designer’s foundation.

The design and use of threads says a lot about the designer’s skill and knowledge.

This is not something that can be faked through hard work. Threads are like the number “0″ in math – simple yet very complex, found everywhere and always changing.

We’ve seen threads evolve throughout history, from the British thread to the American and metric ones, and their use has expanded to different industries and working environments. They come in various types, such as ordinary, aerospace, and transmission threads.

There are also specific threads for sealing pipes and for industry-specific applications.

Analyzing threads in terms of their physical surfaces is quite complex.

3. Tolerance is a philosophy, a thought, and the essence of machinery.

Tolerance is essential because it greatly impacts how well a product performs and the cost of making it. It helps balance the challenge of cutting costs while still delivering top-notch performance. Understanding tolerance also reveals a designer’s creativity, ability to grasp abstract concepts, and logical thinking skills.

In the mechanical design industry I’ve worked in, there are few individuals who truly grasp tolerances. In simple terms, there’s a shortage of understanding. When it comes to books on tolerances, very few authors clearly explain the topic. Most simply add in information without a deep understanding.

4. Mathematics and mechanics determine the height of mechanical design.

Designing a machine involves determining its size, shape, materials, parts, and how they all fit together. Designers need to use a lot of math and tools from scientific disciplines like mechanics to make sure everything is accurate. Information from math and mechanics is more reliable than just guessing. Also, mechanical principles and mechanisms are based on mathematical physics.

5. The level of English (foreign language) determines the development space of designers.

6. If the above are the body of a person, then the way of thinking, design ideas, and design style are the soul of a designer.

Anebon sticks into the basic principle of “Quality is definitely the life of the business, and status may be the soul of it” for big discount custom precision 5 Axis CNC Lathe CNC Machined Part, Anebon have confident that we could offer the high quality products and solutions at resonable price tag, superior after-sales support into the shoppers. And Anebon will build a vibrant long run.

Chinese Professional cnc lathe china and Metal Machining Parts, Anebon rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. Up to 95% products are exported to overseas markets.

Post time: Jan-17-2024