The design of tooling fixtures is a process that is tailored to the specific requirements of a particular manufacturing process. This is done after the machining process of the parts is finalized. When developing the manufacturing process, it is important to consider the feasibility of implementing fixtures. Additionally, modifications to the process can be proposed during the design of the fixture if deemed necessary. The quality of the fixture design is measured by its ability to guarantee stable processing quality of the workpiece, high production efficiency, low cost, convenient chip removal, safe operation, labor savings, as well as easy manufacturing and maintenance.

1. The basic principles of tooling fixture design are as follows:

1. The fixture must ensure stability and reliability of the workpiece positioning during use.

2. The fixture must have sufficient load-bearing or clamping strength to ensure the processing of the workpiece.

3. The clamping process must be simple and fast to operate.

4. Wearable parts must be quickly replaceable, and it is best not to use other tools when conditions permit.

5. The fixture must meet the reliability of repeated positioning during adjustment or replacement.

6. Avoid using complex structures and expensive costs as much as possible.

7. Use standard parts as component parts whenever possible.

8. Form the systematization and standardization of the company’s internal products.

2. Basic knowledge of tooling and fixture design

An excellent machine tool fixture must meet the following basic requirements:

1. The key to ensuring machining accuracy lies in selecting the positioning reference, method, and components correctly. It is also essential to analyze the positioning errors and consider the impact of fixture structure on machining accuracy. This will ensure that the fixture meets the accuracy requirements of the workpiece.

2. To improve production efficiency, use fast and efficient clamping mechanisms to shorten auxiliary time and improve productivity. The complexity of the fixtures should be adapted to the production capacity.

3. Special fixtures with good process performance should have a simple and reasonable structure that enables easy manufacturing, assembly, adjustment, and inspection.

4. Work fixtures with good performance should be easy, labor-saving, safe, and reliable to operate. If feasible, use pneumatic, hydraulic, and other mechanized clamping devices to reduce the operator’s labor intensity. The fixture should also facilitate chip removal. A chip removal structure can prevent chips from damaging the workpiece’s positioning and tool and prevent heat accumulation from deforming the process system.

5. Special fixtures with good economy should use standard components and structures to reduce the manufacturing cost of the fixture. Necessary technical and economic analysis of the fixture solution should be conducted to improve its economic benefits in production, based on the order and production capacity during design.

3. Overview of standardization of tooling and fixture design

1. Basic methods and steps of tooling and fixture design

Preparation before design The original data for tooling and fixture design include the following:

a) Please review the following technical information: design notice, finished part drawings, rough drawings process routes, and other related details. It is important to understand the technical requirements of each process, including the positioning and clamping scheme, processing content of the previous process, rough condition, machine tools and tools used in processing, inspection measuring tools, machining allowances, and cutting quantities.Design notice, finished part drawings, rough drawings process routes, and other technical information, understanding the processing technical requirements of each process, positioning and clamping scheme, processing content of the previous process, rough condition, machine tools and tools used in processing, Inspection measuring tools, machining allowances and cutting quantities, etc.;

b) Understand the production batch size and the need for fixtures;

c) Understand the main technical parameters, performance, specifications, accuracy, and dimensions related to the structure of the fixture connection part of the machine tool used;

d)Standard material inventory of fixtures.

2. Issues to consider in the design of tooling fixtures

The design of a clamp seems relatively simple, but it can cause unnecessary problems if not carefully considered during the design process. The increasing popularity of hydraulic clamps has simplified the original mechanical structure. However, certain considerations must be taken into account to avoid troubles in the future.

Firstly, the blank margin of the workpiece to be processed must be taken into account. If the size of the blank is too large, interference occurs. Therefore, rough drawings should be prepared before designing, leaving plenty of space.

Secondly, smooth chip removal of the fixture is critical. The fixture is often designed in a relatively compact space, which can lead to accumulation of iron filings in the dead corners of the fixture, and poor outflow of the cutting fluid, causing problems in the future. Therefore, problems arising during processing should be considered at the beginning of practice.

Thirdly, the overall openness of the fixture should be considered. Ignoring the openness makes it difficult for the operator to install the card, which is time-consuming and labor-intensive, and is a taboo in the design.

Fourthly, basic theoretical principles of fixture design must be followed. The fixture must maintain its accuracy, so nothing should be designed that goes against the principle. A good design should stand the test of time.

Lastly, the replaceability of positioning components should be considered. The positioning components are severely worn, so quick and easy replacement should be possible. It is best not to design larger parts.

The accumulation of fixture design experience is critical. Good design is a process of continuous accumulation and summary. Sometimes design is one thing and practical application is another. Therefore, it is essential to consider problems that may arise during processing and design accordingly. The purpose of fixtures is to improve efficiency and facilitate operation.

Commonly used work fixtures are mainly divided into the following categories according to their functionality:

01 clamp mold

02 Drilling and milling tooling

03 CNC, instrument chuck

04 Gas and water testing tooling

05 Trimming and punching tooling

06 Welding tooling

07 Polishing jig

08 Assembly tooling

09 Pad printing, laser engraving tooling

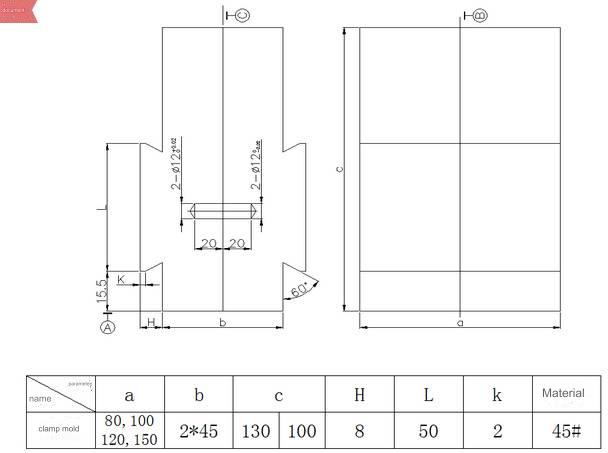

01 clamp mold

Definition: A tool for positioning and clamping based on product shape

Design Points:

1. This type of clamp is mainly used on vises, and its length can be cut as needed;

2. Other auxiliary positioning devices can be designed on the clamping mold, and the clamping mold is generally connected by welding;

3. The above picture is a simplified diagram, and the size of the mold cavity structure is determined by the specific situation;

4. Fit the locating pin with a diameter of 12 in the appropriate position on the movable mold, and the positioning hole in the corresponding position of the fixed mold slides to fit the locating pin;

5. The assembly cavity needs to be offset and enlarged by 0.1mm based on the outline surface of the non-shrunk blank drawing when designing.

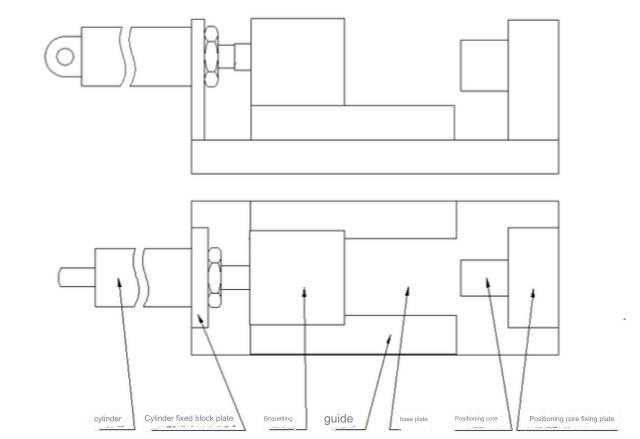

02 Drilling and milling tooling

Design Points:

1. If necessary, some auxiliary positioning devices can be designed on the fixed core and its fixed plate;

2. The above picture is a simplified structural diagram. The actual situation requires corresponding design according to the cnc parts structure;

3. The cylinder depends on the size of the product and the stress during processing. SDA50X50 is commonly used;

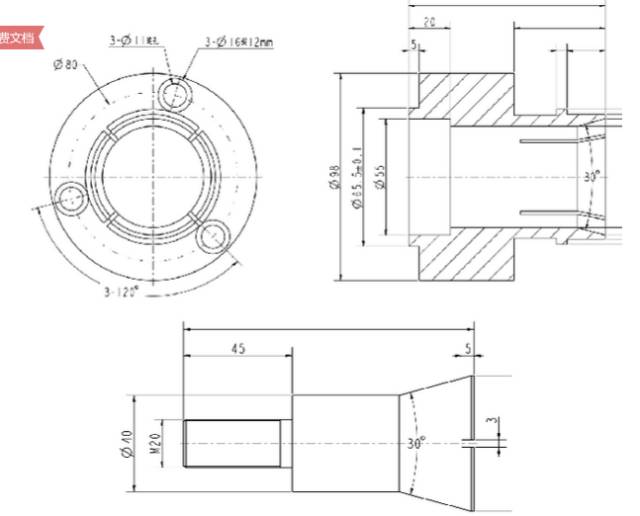

03 CNC, instrument chuck

A CNC chuck

Toe-in chuck

Design Points:

Please find below the revised and corrected text:

1. The dimensions that are not labeled in the picture above are based on the inner hole size structure of the actual product.

2. During the production process, the outer circle that is in positioning contact with the inner hole of the product should leave a margin of 0.5mm on one side. Finally, it should be installed on the CNC machine tool and finely turned to size, to prevent any deformation and eccentricity caused by the quenching process.

3. It is recommended to use spring steel as the material for the assembly part and 45# for the tie rod part.

4. The M20 thread on the tie rod part is a commonly used thread, which can be adjusted according to the actual situation.

Design Points:

1. The above picture is a reference diagram, and the assembly dimensions and structure are based on the actual product’s dimensions and structure;

2. The material is 45# and quenched.

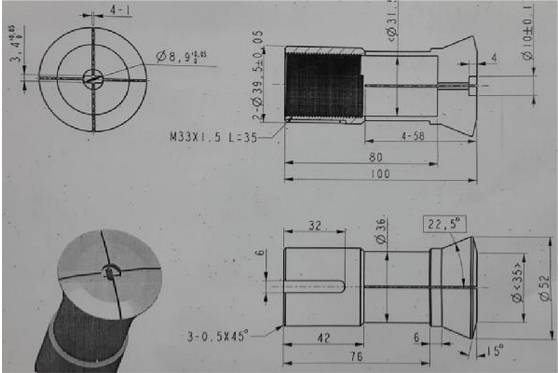

Instrument external clamp

Design Points:

1. The above picture is a reference diagram, and the actual size depends on the inner hole size structure of the product;

2. The outer circle that is in positioning contact with the inner hole of the product needs to leave a margin of 0.5mm on one side during production, and is finally installed on the instrument lathe and finely turned to size to prevent deformation and eccentricity caused by the quenching process;

3. The material is 45# and quenched.

04 Gas testing tooling

Design Points:

1. The image above is a reference picture of the gas testing tooling. The specific structure needs to be designed according to the actual structure of the product. The aim is to seal the product in the simplest way possible, so that the part to be tested and sealed is filled with gas to confirm its tightness.

2. The size of the cylinder can be adjusted as per the actual size of the product. It is also necessary to consider whether the stroke of the cylinder can be convenient for picking up and placing the product.

3. The sealing surface that is in contact with the product generally uses materials with good compression capacity such as Uni glue and NBR rubber rings. Additionally, please note that if there are positioning blocks that are in contact with the appearance surface of the product, try to use white plastic blocks and during use, cover the middle cover with cotton cloth to prevent damage to the appearance of the product.

4. The positioning direction of the product must be taken into account during the design to prevent the leakage of gas from being trapped inside the product cavity and causing false detection.

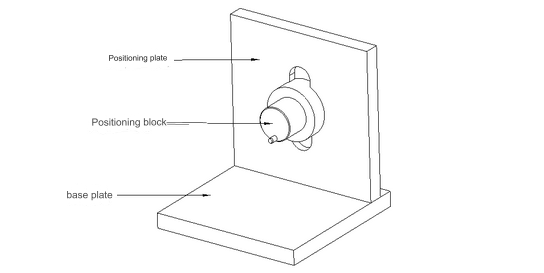

05 Punching tooling

Design points: The image above displays the standard structure of punching tooling. The bottom plate is utilized to affix the workbench of the punch machine easily, while the positioning block is used to secure the product. The structure of the tooling is custom-designed by the actual situation of the product. The center point is encircled by the center point to ensure the safe and convenient picking and placing of the product. The baffle is utilized to easily separate the product from the punching knife, while the pillars are used as fixed baffles. The assembly positions and sizes of these parts can be customized based on the actual conditions of the product.

06 Welding tooling

The purpose of welding tooling is to fix the position of each component in the welding assembly and control the relative size of each component. This is achieved by using a positioning block that is designed according to the actual structure of the product. It is important to note that when placing the product on the welding tooling, a sealed space should not be created between the tooling. This is to prevent excessive pressure from building up in the sealed space, which can affect the size of the parts after welding during the heating process.

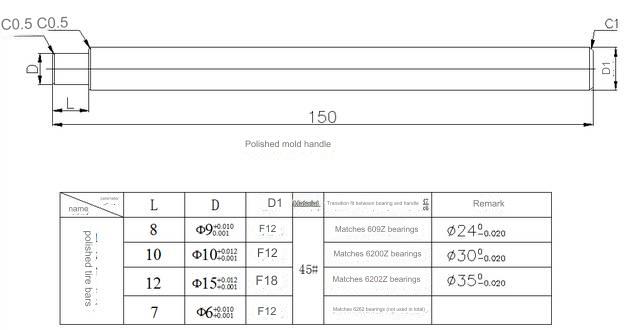

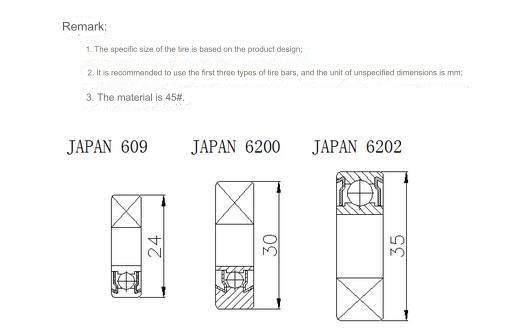

07 Polishing fixture

08 Assembly tooling

Assembly tooling is a device that helps in positioning components during the assembly process. The idea behind the design is to allow easy pick-up and placement of the product based on the assembly structure of the components. It is important that the appearance of the custom cnc aluminum parts are not damaged during the assembly process. To protect the product during use, it can be covered with cotton cloth. When selecting materials for the tooling, it is recommended to use non-metallic materials such as white glue.

09 Pad printing, laser engraving tooling

Design Points:

Design the positioning structure of the tooling according to the engraving requirements of the actual product. Pay attention to the convenience of picking and placing the product, and the protection of the product appearance. The positioning block and the auxiliary positioning device in contact with the product should be made of white glue and other non-metallic materials as much as possible.

Anebon is dedicated to creating high-quality solutions and building relationships with people from all over the world. They are highly passionate and faithful in delivering the best services to their customers. They specialize in China aluminum casting products, milling aluminum plates, customized aluminum small parts CNC, and Original Factory China Extrusion Aluminum and Profile Aluminum.

Anebon aims to adhere to the business philosophy of “Quality first, perfection forever, people-oriented, technology innovation”. They work hard to make progress and innovate in the industry to become a first-class enterprise. They follow a scientific management model and strive to learn professional knowledge, develop advanced production equipment and processes, and create first-rate quality products. Anebon offers reasonable prices, high-quality services, and quick delivery, with the goal of creating new value for their customers.

Post time: Mar-25-2024