1 Learning method of surface modeling

Facing the many surface modeling functions provided by CAD/CAM software, it is very necessary to master the correct learning method in order to achieve the goal of learning practical modeling in a relatively short time.

If you want to master practical modeling techniques in the shortest time, you should pay attention to the following points:

(1) The necessary basic knowledge should be learned, including the construction principles of free-form curves (surfaces). This is very important for the correct understanding of software functions and modeling ideas, the so-called "knife sharpening and not cutting wood by mistake". If you can't understand it correctly, you can't use the surface modeling function correctly, which will inevitably leave hidden dangers for future modeling work and make the learning process repeated. In fact, the basic knowledge required for surface modeling is not as difficult as people imagine. As long as the correct teaching method is mastered, students with high school education can understand it. CNC machining part

(2) To learn software functions in a targeted manner. This has two meanings: one is to avoid too many learning functions, one is that the various functions in the CAD/CAM software are complex and diverse, and beginners often fall into it and cannot extricate themselves. In fact, only a small part of it can be used in actual work, and it is not necessary to ask for everything. For some rare functions, even if they are learned, they are easy to forget and waste time in vain. On the other hand, the necessary and commonly used functions should be focused on learning, and the basic principles and application methods should be truly understood, so as to be thorough.

(3) Focus on learning the basic ideas of modeling. The core of modeling technology is the idea of modeling, not the software function itself. The basic functions of most CAD/CAM software are similar. It is not difficult to learn the operation of these functions in a short period of time, but when faced with actual products, they feel that they are unable to start. This is a problem that many self-students often encounter. This is like learning to shoot, the core technology is not actually the same as the operation of a certain type of firearm. As long as you really master the ideas and skills of modeling, you can become a modeling master no matter what CAD/CAM software you use. aluminum part

(4) A rigorous work style should be cultivated, and “follow the feeling” in modeling learning and work should not be avoided. Each step of modeling should have sufficient basis, not based on feeling and guessing, otherwise it will be harmful.

2 Basic steps of surface modeling

There are three application types for surface modeling: one is original product design, which creates surface models from sketches; the other is surface modeling based on two-dimensional drawings, the so-called drawing modeling; the third is reverse engineering, that is, point survey modeling. Here are the general implementation steps of the second type. stainless steel part

The drawing modeling process can be divided into two stages:

The first stage is modeling analysis to determine the correct modeling ideas and methods. include:

(1) Decompose the product into a single surface or quilt on the basis of correct image recognition.

(2) Determine the type and generation method of each surface, such as ruled surface, draft surface or sweep surface, etc.;

(3) Determine the connection relationship (such as chamfering, cutting, etc.) and connection order between the curved surfaces;

The second stage is the realization of modeling, including:

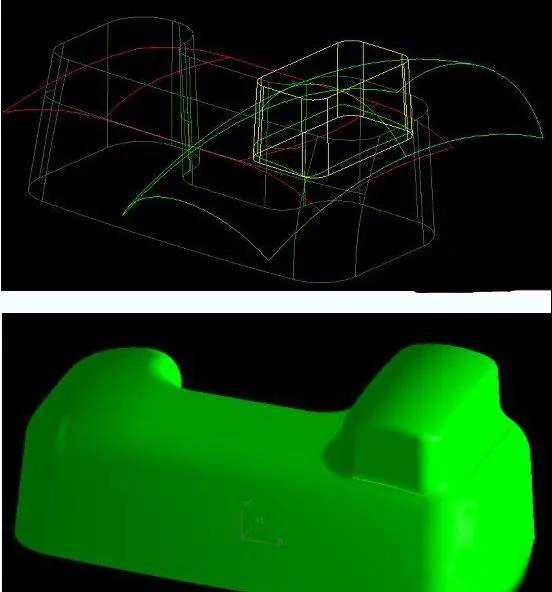

(1) Draw the necessary two-dimensional view contour lines in the CAD/CAM software according to the drawing, and transform each view to the actual position of the space

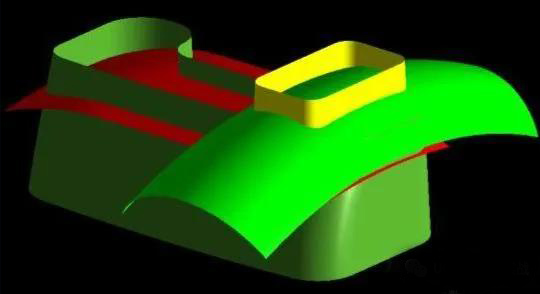

(2) For the type of each surface, use the contour lines in each view to complete the modeling of each surface, as shown in the figure.

(3) For the type of each surface, use the contour lines in each view to complete the modeling of each surface, as shown in Figure 3.

(4) Complete the modeling of the structural part (entity) of the product;

Obviously, the first stage is the core of the entire modeling work, and it determines the operation method of the second stage. It can be said that before drawing the first line on the CAD/CAM software, he has already completed the modeling of the entire product in his mind, so that he has a good idea. The work of the second phase is nothing but a reflection of the work of the first phase on a certain type of CAD/CAM software. In general, surface modeling only needs to follow the above steps, combined with some specific implementation techniques and methods, and no special skills are needed to solve most product modeling problems.

If you'd like to speak to a member of the Anebon team for Cnc Turned Spare Parts,Cnc Milled Components,Precision milling, please get in touch at info@anebon.com

Anebon Metal Products Limited can provide CNC Machining、Die Casting、Sheet Metal Fabrication service, please feel free to contact us.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post time: Mar-09-2021