Requirements of CNC machine tools on tool materials

High hardness and wear resistance

The hardness of the cutting part of the tool must be higher than the hardness of the workpiece material. The higher the hardness of the tool material, the better its wear resistance. The hardness of tool material at room temperature shall be above HRC62. The hardness can be higher than that of ordinary CNC machining parts.

Sufficient strength and toughness

The tool bears excellent pressure in the process of excessive cutting. Sometimes, it works under impact and vibration conditions. To prevent the tool from breaking and breaking, the tool material must have sufficient strength and toughness. Generally, bending strength is used to represent the strength of the tool material, and impact value is used to describe the toughness of the tool material.

higher heat resistance

Heat resistance refers to the performance of tool materials to maintain hardness, wear resistance, strength, and toughness under high temperatures. It is a leading indicator to measure the cutting performance of tool materials. This performance is also known as the red hardness of tool materials.

Good thermal conductivity

The greater the thermal conductivity of the tool material, the more heat is transferred from the tool, which is conducive to reducing the cutting temperature of the tool and improving its durability.

Good processability

To facilitate tool processing and manufacturing, tool materials must have good processing properties, such as forging, rolling, welding, cutting and grindability, heat treatment properties, and high-temperature plastic deformation properties of tool materials. Cemented carbide and ceramic tool materials also require good sintering and pressure-forming properties.

Type of tool material

high-speed steel

High-speed steel is an alloy tool steel composed of W, Cr, Mo, and other alloy elements. It has high thermal stability, strength, toughness, and a certain degree of hardness and wear resistance, so it is suitable for processing non-ferrnonferrous and various metal materials. In addition, because of its sound processing technology, it is ideal for manufacturing complex forming tools, especially powder metallurgy high-speed steel, which has anisotropic mechanical properties and reduces quenching deformation; it isuitableal for manufacturing precision and complex forming tools.

Hard alloy

Cemented carbide has high hardness and wear resistance. When cutting CNC turning parts, its performance is better than high-speed steel. Its durability is several to dozens of times that of high-speed steel, but its impact toughness is poor. Because of its excellent cutting performance, it is widely used as a tool material.

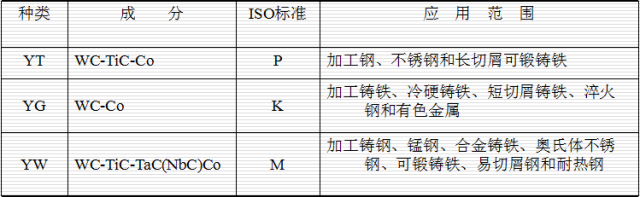

Classification and marking of cemented carbides for cutting tools

Coated blade

1) The coating material of the CVD method is TiC, which increases the durability of cemented carbide tools by 1-3 times. Coating thickness: The cutting edge is blunt and conducive to improving speed life.

2) The coating materials of the PVD physical vapor deposition method are TiN, TiAlN, and Ti (C, N), which improves the durability of cemented carbide tools by 2-10 times. Thin coating; Sharp edge; It is beneficial for reducing cutting force.

★ Maximum thickness of coating ≤ 16um

CBN and PCD

Cubic boron nitride (CBN) The hardness and thermal conductivity of cubic boron nitride (CBN) are inferior to diamond, and it has high thermal and chemical stability. Therefore, it is suitable for machining hardened steel, hard cast iron, superalloy, and cemented carbide.

Polycrystalline diamond (PCD) When PCD is used as a cutting tool, it is sintered on the cemented carbide substrate. It can finish wear-resistant, high hardness, non-metallic, and nonferrononferrousaterials such as cemented carbide, ceramics, and high silicon aluminum alloy.

★ ISO machine clamp blade material classification ★

Steel parts: P05 P25 P40

Stainless steel: M05 M25 M40

Cast iron: K05 K25 K30

★ The smaller the number is, the more complex the blade is, the better the wear resistance of the tool is, and the worse the impact resistance is.

★ The larger the number is, the softer the blade is, the better the tool's impact resistance and poor wear resistance.

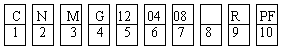

Convertible to blade model and ISO representation rules

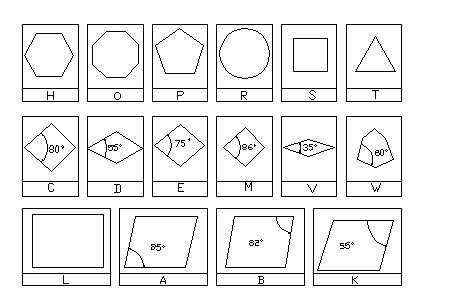

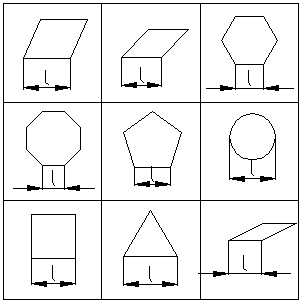

1. Code representing the shape of the blade

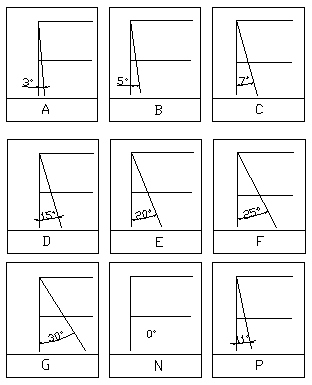

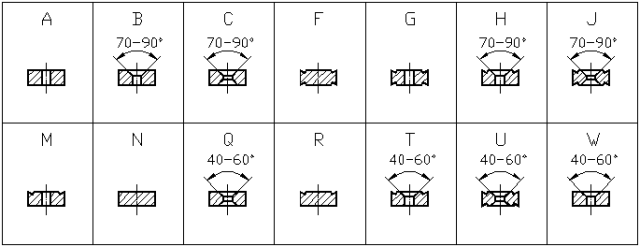

2. Code representing the back angle of the leading cutting edge

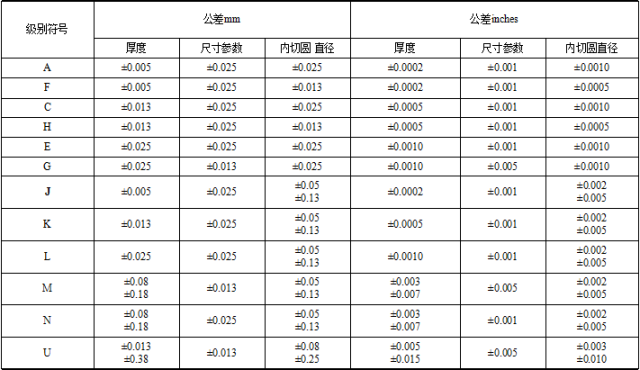

3. Code representing the dimensional tolerance of the blade

4. Code representing the chip breaking and clamping form of the blade

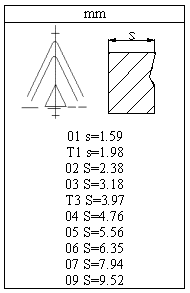

5. Represented by the length of cutting edge

6. Code representing the thickness of the blade

7. Code representing the polishing edge and R angle

Meaning of other figures

Eight refers to the code indicating special needs;

9 represents the code of feed direction; for example, code R represents the right feed, code L represents the left feed, and code N represents the intermediate feed;

10 represents the code of chip breaking groove type;

11 represents the material code of the tool company;

cutting speed

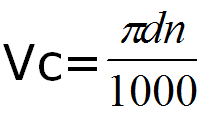

Calculation formula of cutting speed Vc:

In the formula:

D - rotary diameter of workpiece or tooltip, unit: mm

N - rotational speed of workpiece or tool, unit: r/min

The Speed of Machining Thread with Ordinary Lathe

Spindle speed n for turning thread. When cutting thread, the spindle speed of the lathe is affected by many factors, such as the size of the thread pitch (or lead) of the workpiece, the lifting and lowering characteristics of the drive motor, and the speed of thread interpolation. Therefore, specific differences exist in the spindle speed for the turning thread for different CNC systems. The following is the formula for calculating the spindle speed when turning threads on general CNC lathes:

In the formula:

P - thread pitch or lead of workpiece thread, unit: mm.

K - insurance coefficient, generally 80.

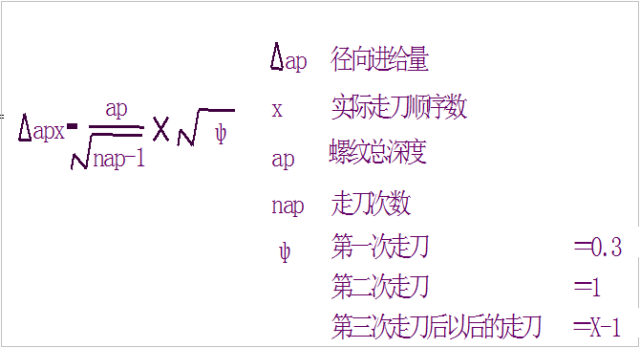

Calculation of each feed depth for machining thread

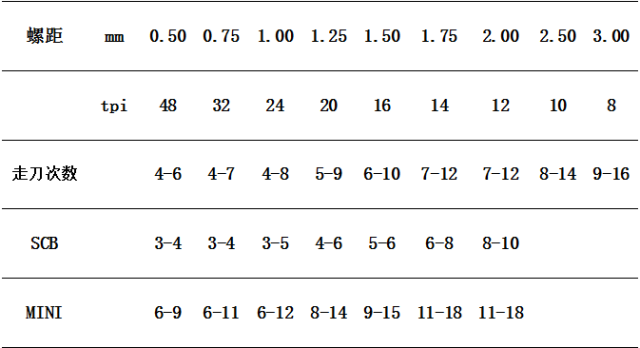

Number of threading tool paths

1) Rough machining

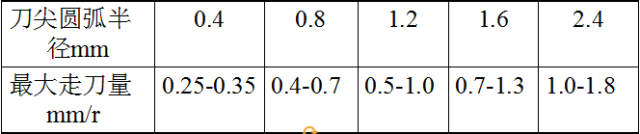

Empirical calculation formula of rough machining feed: f rough=0.5 R

Where: R ------ tool tip arc radius mm

F ------ rough machining tool feed mm

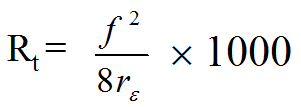

2) Finishing

In the formula: Rt ------ contour depth µ m

F ------ Feed rate mm/r

r ε ------ Radius of tooltip arc mm

Differentiate rough and finish turning according to feed rate and chip-breaking groove

F ≥ 0.36 rough machining

0.36 > f ≥ 0.17 semi-finishing

F < 0.17 finish machining

It is not the material of the blade but the chip-breaking groove that affects the rough and finished machining of the blade. The cutting edge is sharp if the chamfer is less than 40um.

Post time: Nov-29-2022