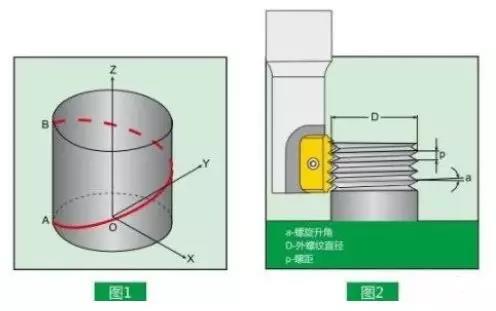

To achieve thread milling, the machine must have three-axis linkage. The helical interpolation is a function of CNC machine tools. The tool controls the tool to realize the helical trajectory. The helical interpolation is formed by the plane circular interpolation and the linear motion perpendicular to the plane.

For example: The spiral trajectory from point A to point B (Figure 1) is linked by the X-Y plane circular interpolation motion and the Z linear linear motion.

For most CNC systems, this function can be implemented by the following two different instructions.

G02: Instantaneous needle circular interpolation command

G03: Counterclockwise circular interpolation instruction

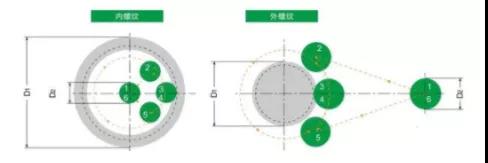

The thread milling motion (Figure 2) shows that it is formed by the tool's own rotation and the machine's helical interpolation motion. During the interpolation of Igrid circles,

Using the geometric form of the prop, combined with the movement of the tool to move the pitch in the Z axis direction, the required thread is processed. Thread milling can use

The following three cut-in methods.

① Arc cut method

② Radial cut-in method

③ Tangential entry method

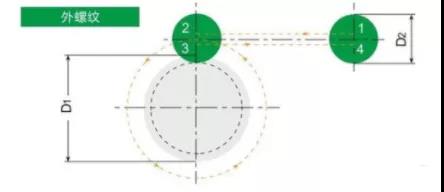

① Arc cut method

With this method, the tool cuts in smoothly, leaving no cutting marks and no vibration, even when processing hard materials. The programming of this method is a bit more complicated than the radial cut-in method, and it is recommended to use this method when machining precision threads.

1-2: Quick positioning

2-3: The tool cuts tangentially along the arc feed, while interpolating the feed along the Z axis

3-4: 360 ° full circle for thread interpolation motion, axial movement one lead

4-5: The tool cuts tangentially along the arc feed and performs interpolation motion along the Z axis

5-6: Quick return

② Radial cut-in method

This method is the easiest, but sometimes the following two situations occur

First, there will be very small vertical marks at the cut-in and cut-out points, but it will not affect the quality of the thread

Second, when processing very hard materials, when cutting into nearly full teeth, due to the increase of the contact area between the tool and the workpiece, the phenomenon of vibration may occur. In order to avoid vibration when cutting into the full tooth type, the feed amount should be reduced to 1/3 of the spiral interpolation supply as much as possible.

1-2: Quick positioning

2-3: 360 ° full circle for helical interpolation motion, one lead for axial movement

3-4: radial return

③ Tangential entry method

This method is very simple and has the advantages of the arc cutting method, but it is only suitable for the milling of external threads.

1-2: Quick positioning

2-3: 360 ° full circle for thread interpolation motion, axial movement by one lead

3-4: Quick return

www.anebon.com

Post time: Dec-01-2019