New Fashion Design for Mechanical Components – 3 Axis Cnc Mill – Anebon

New Fashion Design for Mechanical Components – 3 Axis Cnc Mill – Anebon Detail:

Driving device and auxiliary device for CNC milling machine:

● Drive unit, which is the driving part of the CNC machine tool actuator, including the spindle drive unit, feed unit, spindle motor and feed motor. He drives the spindle and feed through an electrical or electro-hydraulic servo system under the control of a numerical control unit. When several feeds are linked, the positioning, straight line, plane curve and space curve can be processed.

● Auxiliary devices, some necessary components of the index control machine to ensure the operation of CNC machine tools, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange tables, CNC rotary tables and CNC indexing heads, as well as tools and monitoring and inspection devices.

● Programming and other ancillary equipment, which can be used to program and store parts outside the machine.

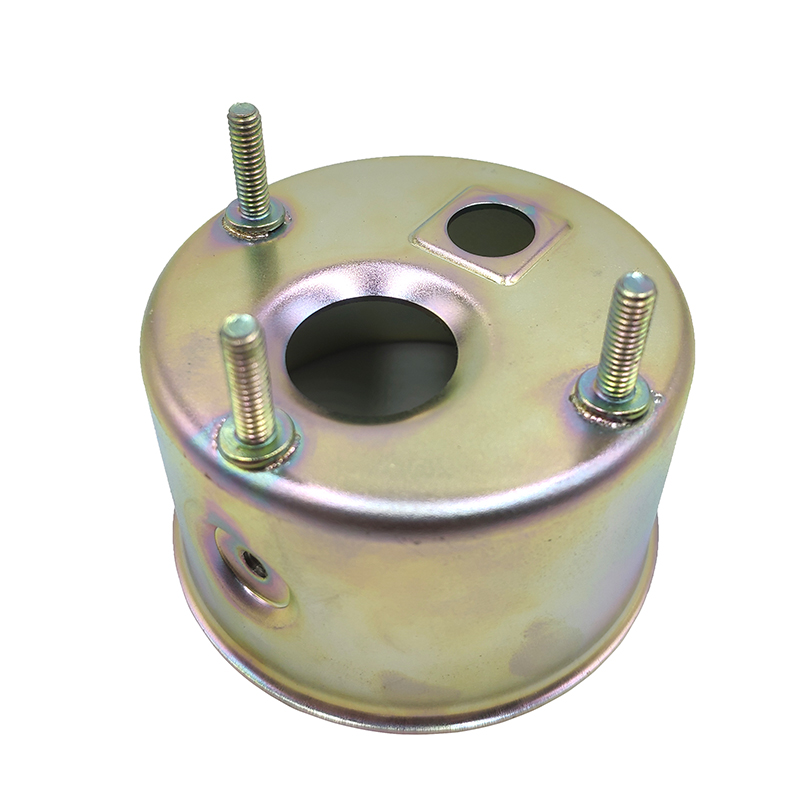

CNC machining part , milling parts , turning accessory,CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Product detail pictures:

Related Product Guide:

Micron Solutions, Inc. Reports 2019 First Quarter Results NYSE:MICR | Precision Machining Part

Meet the CoolGeek Soundesk | Precision Machining Part

China CNC processing parts, CNC cutting parts of the minimum order volume, he has passed the national qualification certification project, and in our major industry has received high praise.Our professional engineering team is ready to provide you with advice and feedback.We are also able to provide you with samples to meet your specification requirements. New Fashion Design for Mechanical Components – 3 Axis Cnc Mill – Anebon , The product will supply to all over the world, such as: Sudan, Madrid, Melbourne, Factory Outlets for China Die-Casting and Aluminum Die Casting, machining service, medical machining, metal stamping products, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which are going to be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.