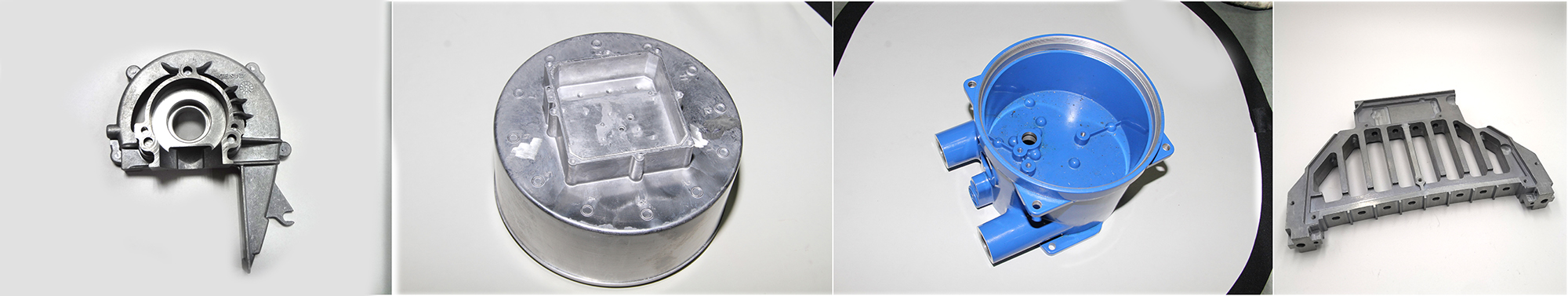

Customized Auto Metal Parts Die Casting

Ingproses castingnyadari cetakan baja sing biasane bisa ngasilake ewu casting kanthi cepet. Cetakan kudu digawe ing paling ora rong bagean supaya casting bisa dibusak. Siklus casting diwiwiti karo mesin die casting clamping loro jamur halves tightly bebarengan. Aluminium molten disuntikake menyang rongga ing ngendi iku solidifies cepet.

Akeh bagean saka jinis padha sing bisa matak kanggo produksi massal. Sanajan tekanan dhuwur digunakake ing proses manufaktur, kualitas casting sing dhuwur isih bisa digayuh. Ingproses die castingutamané cocok kanggo produksi bagean banget tipis (nganti 1 mm) (entheng).

Produk sing asring diprodhuksi: diprodhuksi ing industri mobil, kayata roda, blok silinder, kepala silinder, badan katup lan manifold.

| Proses: | 1) Die Casting / Ekstrusi Profil 2) Mesin: CNC ngowahi, Milling, Drilling, Grinding, Reaming lan Threading 3) Perawatan lumahing 4) Inspeksi lan Packaging |

| Bahan kasedhiya: | 1) Paduan Aluminium Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, lsp. 2) Aluminium Alloys Profil Extrusion: 6061, 6063 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. |

| Perawatan lumahing: | Polishing Ditembak Blasting Sandblasting Powder Coating Anodizing Plating Chrome Pasif E-lapisan T-lapisan lsp. |

| Toleransi: | +/- 0,05 mm |

| Bobot saben Unit: | 0,01-50KG |

| Wektu Lead Order: | 20-45 Dina (Miturut Jumlah lan Kompleksitas Produk |

| Cnc Diuripake Part | Baja Cnc Kab | bagean pabrikan sheet metal | casting aluminium |

| Poros Motor Hollow | Aluminium Cnc Nguripake Parts | proses produksi sheet metal | seng die casting |

| Diuripake Parts | Diuripake Aluminium | proses produksi sheet metal | bagean casting |

Tulis pesen ing kene lan kirimake menyang kita