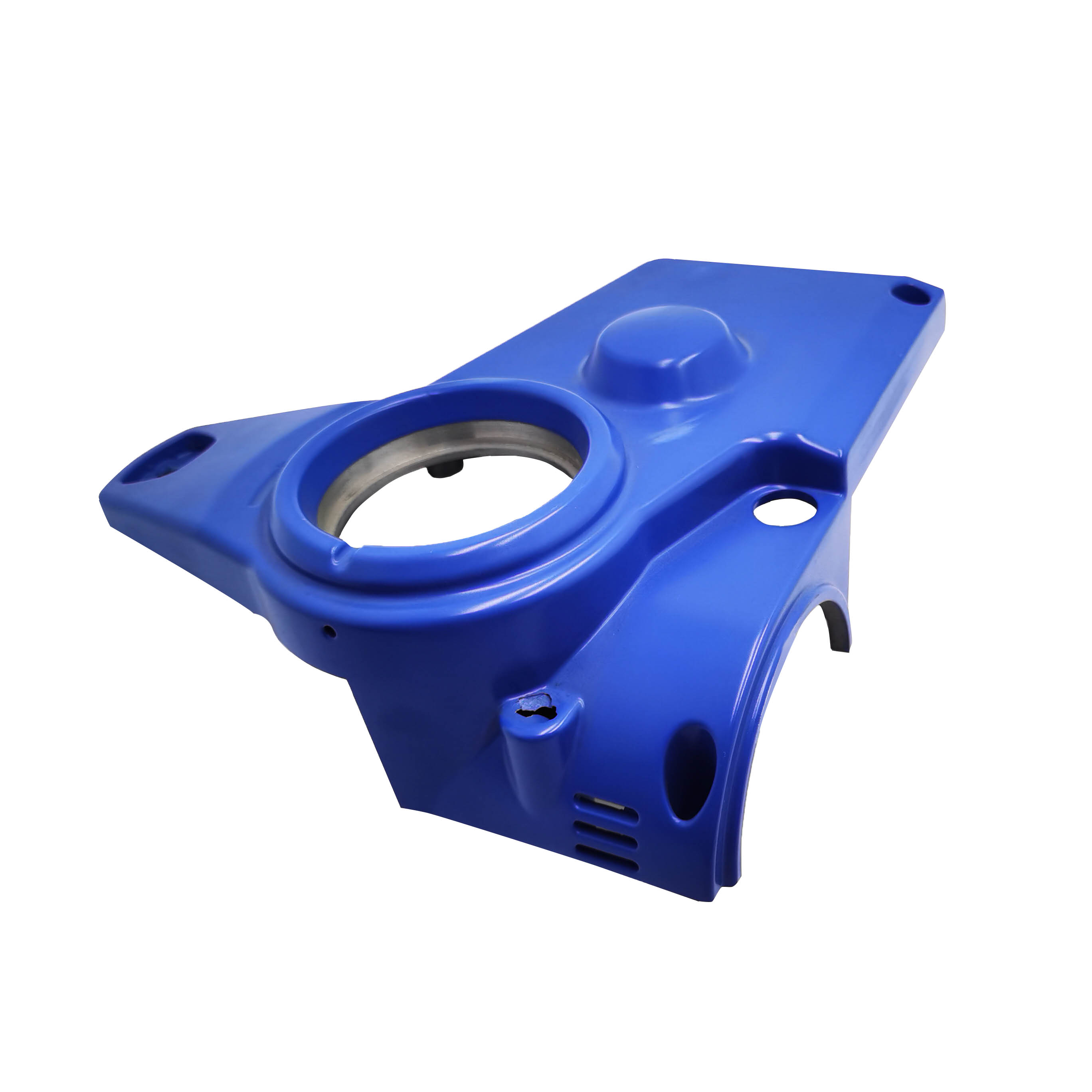

China Wholesale Die Casting Mold Cost Factory – Chinese factory bicycle aluminum alloy casting service accessories – Anebon

China Wholesale Die Casting Mold Cost Factory – Chinese factory bicycle aluminum alloy casting service accessories – Anebon Detail:

Our Products

Advantages:

1. Lightweight–The weight of our aluminum is light.

2. Good mechanical properties

3. Corrosion resistant

4. High thermal and electrical conductivity

5. High strength—even at high temperatures

6. Retain high dimensional stability with thin walls and complex shapes

Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of Quality Inspection for China CNC Machined Racing Motorcycle Bicycle Parts Machining Spare Parts, We’ve been searching ahead to developing cooperative relationships with you. Remember to make contact with us for more details.

| Die Casting | |

| Grade | A356 A360 AC2C |

| Heat Treatment | T6 Heat Treatment Continue |

| Surface finished | Sandblasting, painting, polishing,powder coating |

| Applied software | Pro/E,Auto CAD,Solid Work ,CAXA, UG, CAD/CAM/CAE |

| Machining equipments | Gravity Casting machine -23 Sets |

| Sand Core machine -15 Sets | |

| Continue T6 heat treatment machine-1 sets | |

| Sand blasting machine-3 sets | |

| CNC -80 sets | |

| CNC Lathe- 25 sets | |

| Drilling machine – 100 sets | |

| Main products | Intake Manifold series,Cylinder Head series and Pump series |

| Train spare parts and all kinds of aluminum casting parts | |

| They can be produced according to customers’ designed drawings | |

| Service | OEM service available |

Other Product Display

Some detailed about our Products:

1. Product Aluminum: Die Casting Anodized Machinery Parts

2. Material Aluminum: alloy ADC10, ADC12, A360, A380; zamark, etc

3. Manufactuering Process: Drawing and Sample…Mould Developing…Die Casting…Deburring…Drilling and Threading…CNC Machining…Polishing…Surface Treatment…Assembling…Quality Inspection..Packing…Shipping

die casting and forging workshop

4. Machine Capacity: Die casting machine 120 ton to 1200 ton

5. Surface Treatment: Polishing, Sandblasting, Painting, Powder Coating, Galvanizing, Chrome Coating, Anodizing

6. Application Example: Pneumatic components parts; Led light housing; Led heatsink; Auto, motocyle, bicycle parts; Furniture accessories; Power tool housing; Pump housing; Mechanical parts, etc

7. Drawing Available: IGS, STEP, SLD, X-T, XDF, DWG, SAT, STL, etc

| aluminum die casting parts | aluminium die casting product |

| die casting plastics | die-casting fittings |

| custom die casting | aluminium alloy die casting |

Company Profile

Packaging And Logistics

Product detail pictures:

Related Product Guide:

Mansfield adult education program to graduate 116 individuals on June 6 | Education | Cnc Machined Part

Optical Diamond Turning | NiPro Optics Inc. | Mar 2019 | Precision Machining Part

China CNC processing parts, metal parts processing factory manufacturers, we have enough experience in producing products based on samples or drawings.Warmly welcome domestic and foreign customers to visit the company, work together to create a better future. Keep in mind that "customer first, quality first", we work closely with consumers to provide them with efficient and experienced wholesale China 12 years factory OEM metal milling cutting service aluminum CNC machining parts, in order to achieve mutual advantages, Anebon in communication with overseas customers, fast delivery, the best quality and long-term cooperation, widely promote our globalization strategy. China Wholesale Die Casting Mold Cost Factory – Chinese factory bicycle aluminum alloy casting service accessories – Anebon , The product will supply to all over the world, such as: Berlin, Costa Rica, Frankfurt, Wholesale China Machinery Parts and Machining Parts, metal stampings, sheet fabrication, metal cnc servicesIf you need to have any of our products and solutions, or have other things to be produced, be sure to send us your inquiries, samples or detailed drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!