China Wholesale Custom Metal Milling Suppliers – Stainless Steel Cnc – Anebon

China Wholesale Custom Metal Milling Suppliers – Stainless Steel Cnc – Anebon Detail:

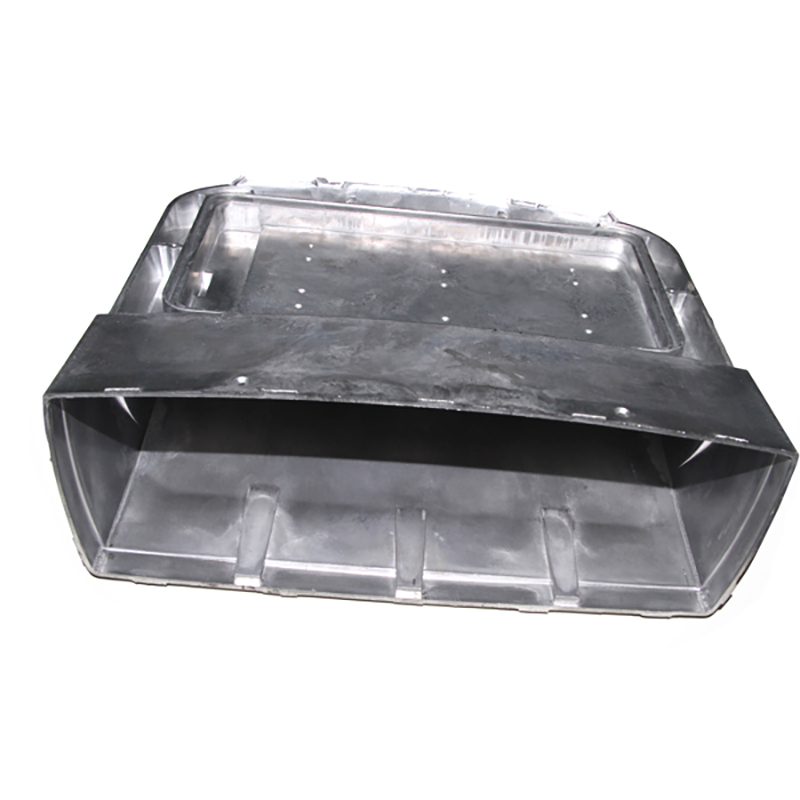

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

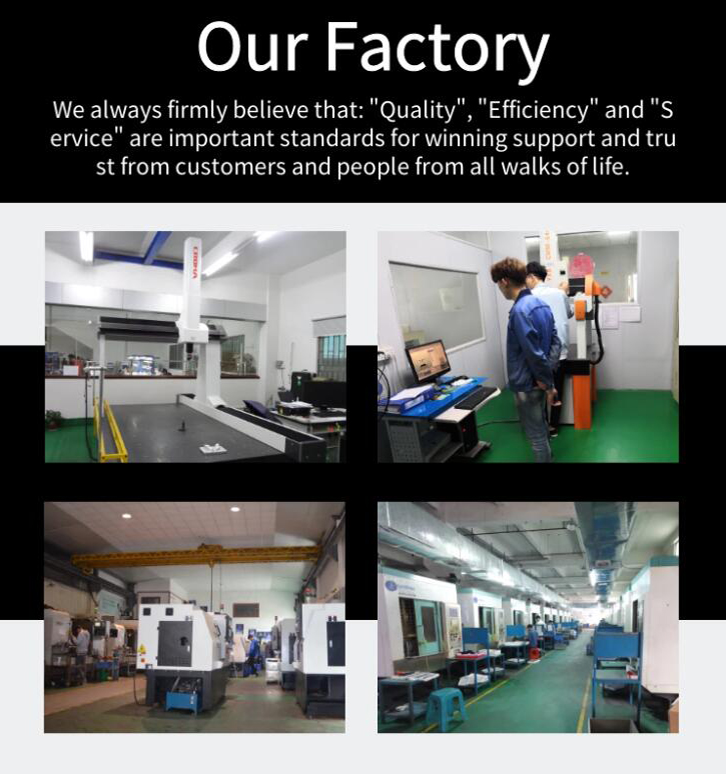

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

Product detail pictures:

Related Product Guide:

Milling Machines Market Outlook 2021: Top Companies, Trends and Future Prospects Details for Business Development and CAGR of 5.83% | Precision Machining Part

Global CNC Machine Tool Markets Report 2019-2025: Focus on the Chinese Industry Featuring 12 Foreign and 20 Chinese Manufacturers | Metal Turning

Wholesale China CNC processing, CNC processing parts, we have enough experience in producing products based on samples or drawings.Warmly welcome domestic and foreign customers to visit the company, work together to create a better future. China Wholesale Custom Metal Milling Suppliers – Stainless Steel Cnc – Anebon , The product will supply to all over the world, such as: Lithuania, Saudi Arabia, Ukraine, Anebon mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for China Gold Supplier for Precision Brass, metal machining service,cnc milling service, CNC Turning Milling Machinery Parts, CNC Machining Parts, CNC Machined Part, Together with our efforts, our goods have won the trust of buyers and been very salable equally here and abroad.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!