China manufacture high quality customized aluminum alloy die casting parts

Advantages:

1. Lightweight--The weight of our aluminum is light.

2. Good mechanical properties

3. Corrosion resistant

4. High thermal and electrical conductivity

5. High strength—even at high temperatures

6. Retain high dimensional stability with thin walls and complex shapes

100% Original China Aluminum Casting, Die Casting Part, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

| Die Casting | |

| Grade | A356 A360 AC2C |

| Heat Treatment | T6 Heat Treatment Continue |

| Surface finished | Sandblasting, painting, polishing,powder coating |

| Applied software | Pro/E,Auto CAD,Solid Work ,CAXA, UG, CAD/CAM/CAE |

| Machining equipments | Gravity Casting machine -23 Sets |

| Sand Core machine -15 Sets | |

| Continue T6 heat treatment machine-1 sets | |

| Sand blasting machine-3 sets | |

| CNC -80 sets | |

| CNC Lathe- 25 sets | |

| Drilling machine - 100 sets | |

| Main products | Intake Manifold series,Cylinder Head series and Pump series |

| Train spare parts and all kinds of aluminum casting parts | |

| They can be produced according to customers’ designed drawings | |

| Service | OEM service available |

Some detailed about our Products:

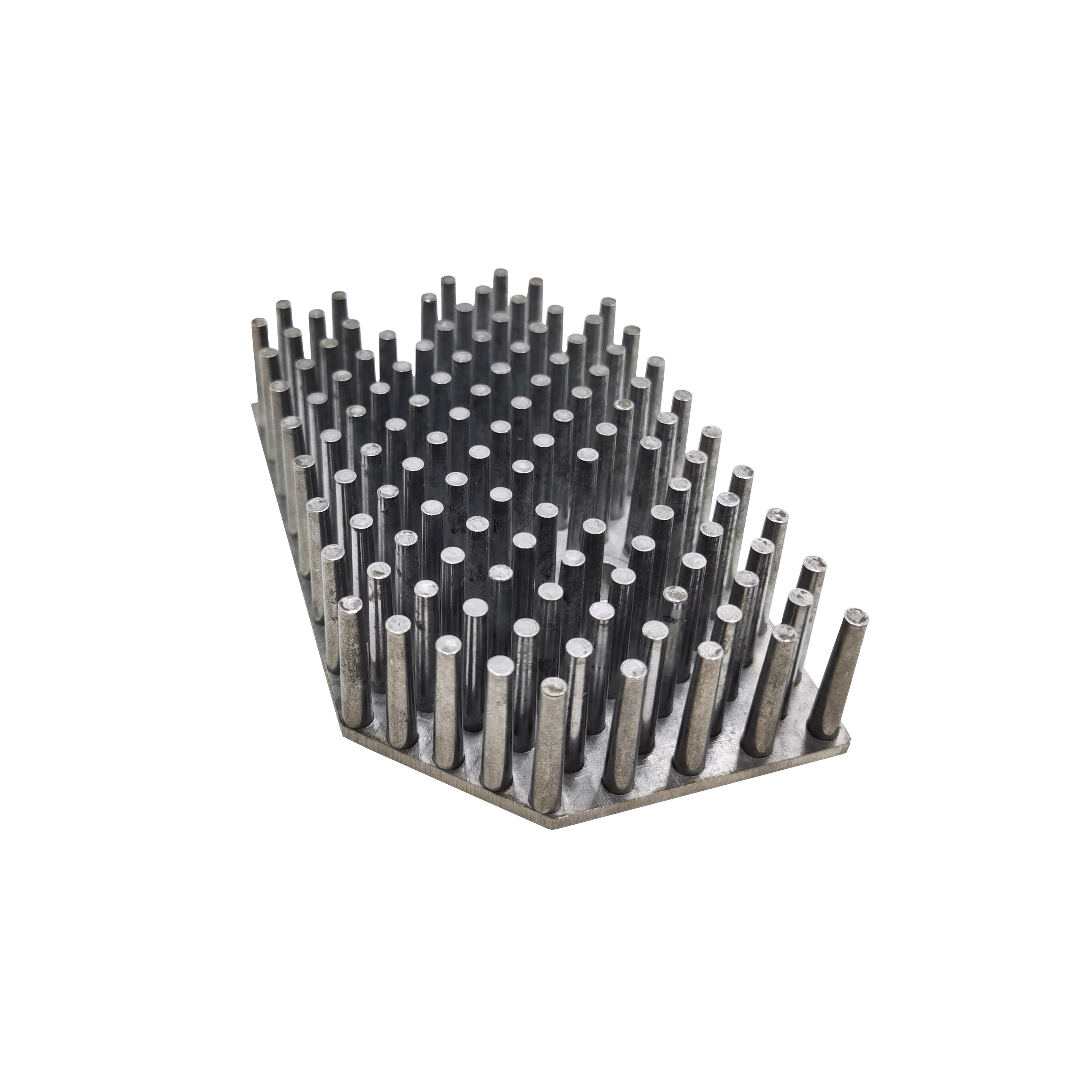

1. Product Aluminum: Die Casting Anodized Machinery Parts

2. Material Aluminum: alloy ADC10, ADC12, A360, A380; zamark, etc

3. Manufactuering Process: Drawing and Sample...Mould Developing...Die Casting...Deburring...Drilling and Threading...CNC Machining...Polishing...Surface Treatment...Assembling...Quality Inspection..Packing...Shipping

die casting and forging workshop

4. Machine Capacity: Die casting machine 120 ton to 1200 ton

5. Surface Treatment: Polishing, Sandblasting, Painting, Powder Coating, Galvanizing, Chrome Coating, Anodizing

6. Application Example: Pneumatic components parts; Led light housing; Led heatsink; Auto, motocyle, bicycle parts; Furniture accessories; Power tool housing; Pump housing; Mechanical parts, etc

7. Drawing Available: IGS, STEP, SLD, X-T, XDF, DWG, SAT, STL, etc

| aluminum die casting parts | aluminium die casting product |

| die casting plastics | die-casting fittings |

| custom die casting | aluminium alloy die casting |

Well-designed China Logistics, Shipping Agent, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality merchandise we offer you, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent for you timely for the inquiries. So be sure to get in touch with us by sending us emails or contact us if you have any concerns about our firm. We're looking forward to your inquiries.