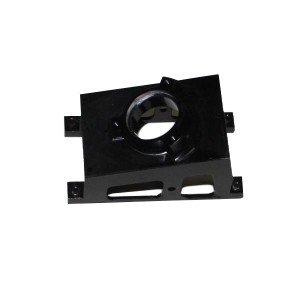

China Gold Supplier for Customized Machining Parts/cnc Turning Cnc Machined Titanium Fixed Parts

In order to best meet client’s needs, all of our operations are strictly performed in line with our motto “High Quality, Competitive Price, Fast Service” for China Gold Supplier for Customized Machining Parts/cnc Turning Cnc Machined Titanium Fixed Parts, We sincerely welcome you come to visit us. Hope we have good cooperation in the future.

In order to best meet client’s needs, all of our operations are strictly performed in line with our motto “High Quality, Competitive Price, Fast Service” for Cnc Turning Parts, fast prototyping, Titanium Parts, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right goods to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

Product Detail:

CNC turning parts are lathe machining, and lathe machining is part of machining. The turning machine mainly uses a turning tool to turn the rotating workpiece. On the lathe, drills, reamer, reamer, taps, dies and knurling tools can also be used for machining. Lathes are mainly used for machining shafts, discs, sleeves and other workpieces with a rotating surface. They are the most widely used type of machine tool in machine building and repair plants.

|

Workable size |

Tolerance |

|

|

CNC Turning |

φ0.5 – φ300 * 750 mm |

+/-0.005 mm |

|

CNC Milling |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

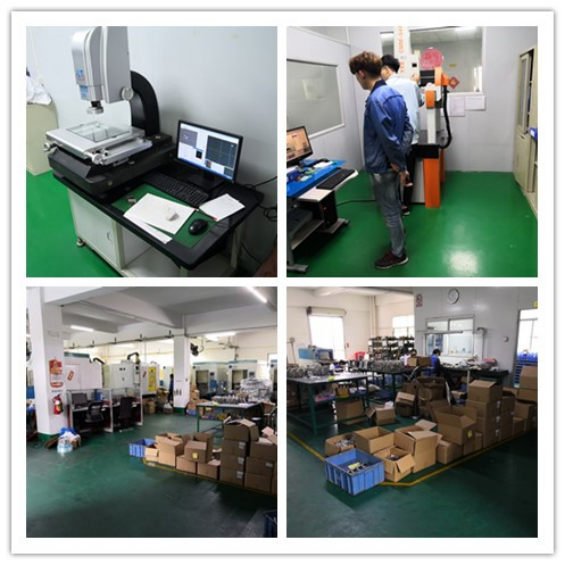

Test Equipment |

Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

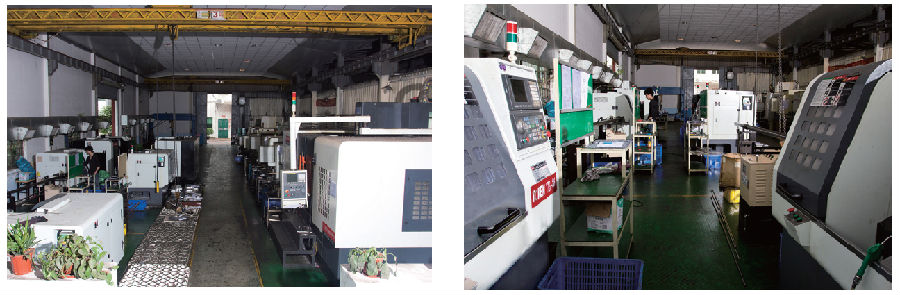

| Manufacturing Capabilities | Machines: 3-axis Machining centers; CNC turning centers; Stamping machines; Tapping machines; Cutting machines; Polishing machines; sandblasting machines; |

| Materials | Aluminum; Brass; Bronze; Copper; Stainless Steel; Steel / Steel Alloys; |

| Additional Services | CAD/CAM Support; Design Assistance; Just-in-Time Delivery; Prototype Services; Low Volume Production; High Volume Production; Reverse Engineering; Assembly Services; |

| Drawing Software | Solid work, Pro/E, AutoCAD CAM |

| Surface Treatment | As requirement, Zinc plated, Nickel Plated, anodize |

| Standard Available | GB, DIN, ISO, ANSI, ASME, IFI, JIS, BSW, AS, Q, HJ, BS, PEN |

| Delivery Time | 15-25 working days after order confirmation |

| Payment Term | T/T,L/C Western Union, etc |

|

Machining |

Milling |

Turning |

|

Cnc Machining Techniques

|

Cnc Milling Theory

|

Cnc Turning Simulation Software

|

|

Cnc Machining Supplier

|

Cnc Milling Techniques

|

Cnc Turning Setting

|

|

Cnc Machining Stainless Steel

|

Cnc Milling Table |

Cnc Turning Setting Procedure

|