Auto Parts Market In Dongguan CNC Milled Parts, Turned Parts ,Cnc Machined AluminumComponents

Getting customer satisfaction is our company’s aim for good. We are going to make good endeavours to create new and top-quality solutions, fulfill your specific specifications and provide you with pre-sale, on-sale and after-sale services for Auto Parts Market In Dongguan CNC Milled Parts, Turned Parts ,Cnc Machined AluminumComponents, We warmly welcome domestic and abroad buyers deliver inquiry to us ,we now have 24hours doing work team! Anytime anywhere we are still here to be your partner.

Getting customer satisfaction is our company’s aim for good. We are going to make good endeavours to create new and top-quality solutions, fulfill your specific specifications and provide you with pre-sale, on-sale and after-sale services for Auto Parts Market In Guangzhou, Machined Steel, Turned Parts Cnc, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products and solutions to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We’ve honored to receive recognition from our customers. Till now now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of “quality of survival, the credibility of development” for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

We will do our utmost to work hard to accelerate our position in the world’s leading and high-tech companies, and accelerate the rapid delivery of customized 3/4/5 Aixs Cnc processing machinery spare parts. Cnc milling anodized aluminum parts rapid prototyping。

Auto parts processing steps:

1. CNC computer Milling, through the CNC processing equipment according to the path set by the program, on the basis of the raw materials of the product, to obtain the prototype of the part.

2. It is hand-processed, after the prototype of the part comes out, the appearance of the sample will have some burrs and extra parts of the corners, the staff should use sandpaper to smooth, so that the appearance becomes smooth and refined.

3. Laser engraving, that is using laser technology to remove the paint of the sample’s appearance, so that a part of the sample is transparent.

4. Oxidation, that is, anodizing, It is the function of electrolysis. Because of the poor corrosion resistance of the oxidation formed after the treatment and the low cost of the website, it is rarely used in the process.

5. Drawing, It is to pull out a strip of fine marks on the parts’ appearance, such a treatment will make the sample feel better.

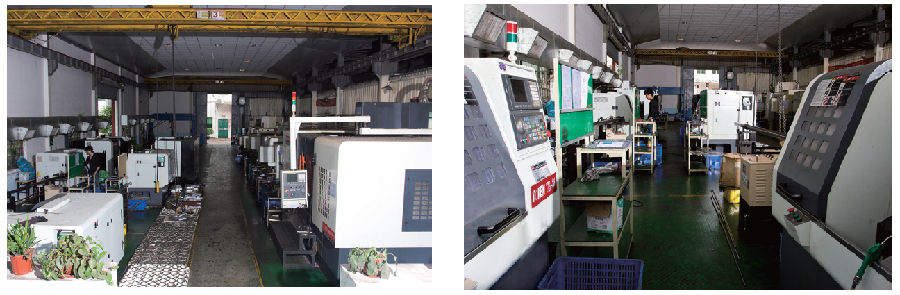

Anebon has a wide range of imported CNC Milling machines from Vertical Mills to Hi-Speed Fanuc Robodrill machines and 5-Axis Machining Centers. Anebon utilize the latest in CAD/CAM technology. Our Master CAM Software enables us to design and simulate 2D/3D models & components.