2017 wholesale price 5 Axis Cnc Machining Services – Metal Mill – Anebon

2017 wholesale price 5 Axis Cnc Machining Services – Metal Mill – Anebon Detail:

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers’ requirement.

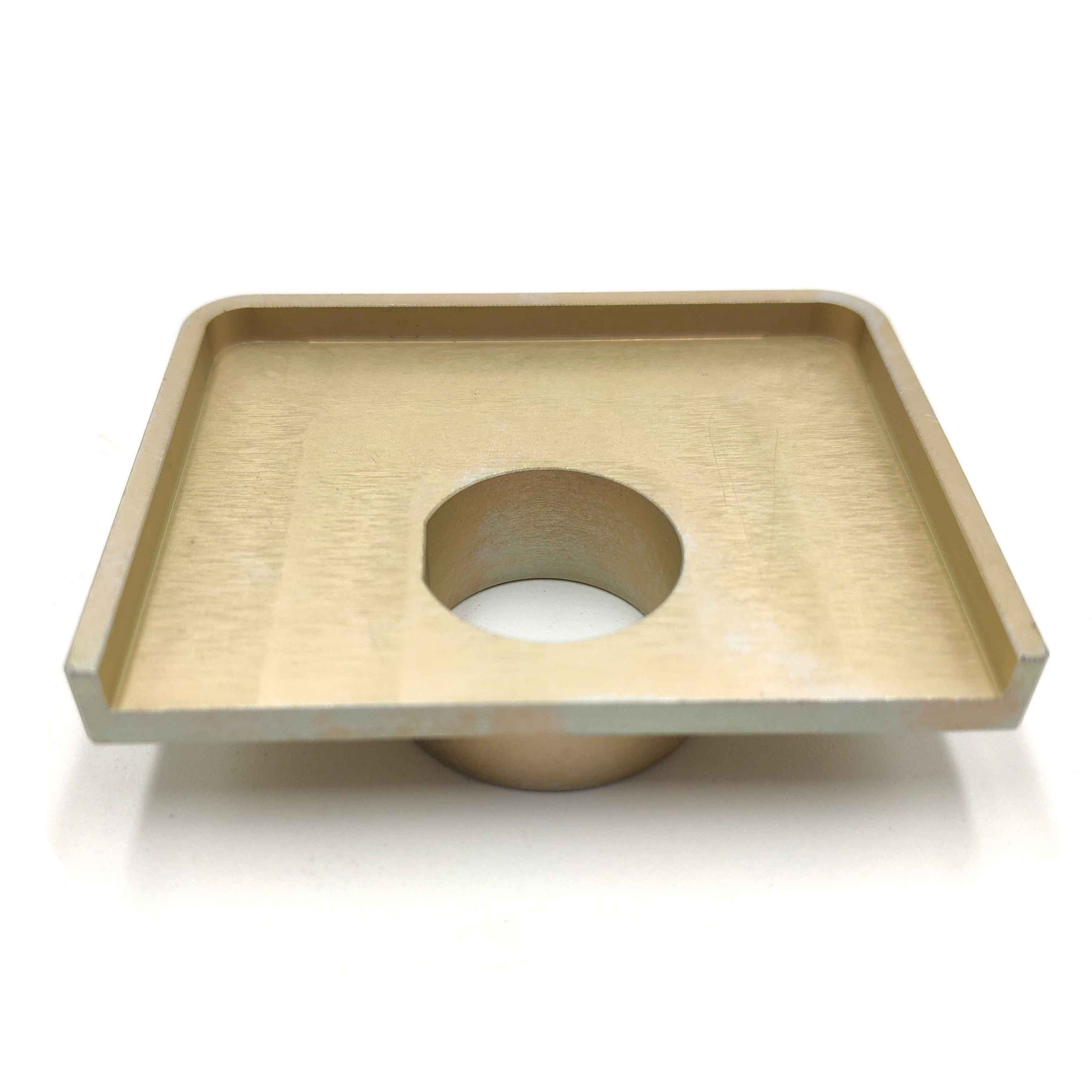

Product detail pictures:

Related Product Guide:

Compact machining centre offers higher productivity and accuracy | Precision Machining Part

From hard drive to over-heard drive: Boffins convert spinning rust into eavesdropping mic • The Register | Precision Turned Component

We have advanced, efficient, high standard machines including various CNC milling machines and lathes, flat grinder, inner flat mill, Wedm-ls, Wedm-hs etc.We also have the state-of-the-art testing equipment.Parts with tolerances of up to ± 0.002mm can be supported. 2017 wholesale price 5 Axis Cnc Machining Services – Metal Mill – Anebon , The product will supply to all over the world, such as: Casablanca, San Francisco, Yemen, We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for Factory For Customized Precision Metal Aluminum Plastic Machined/Machinery/Machine CNC Turnning/Milling/Welding/Stamping Machining Parts/die casting service for Motorcycle Auto Spare Parts, We sincerely welcome buddies to negotiate business enterprise and start cooperation with us. We hope to join hands with good friends in different industries to produce a brilliant long term.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.