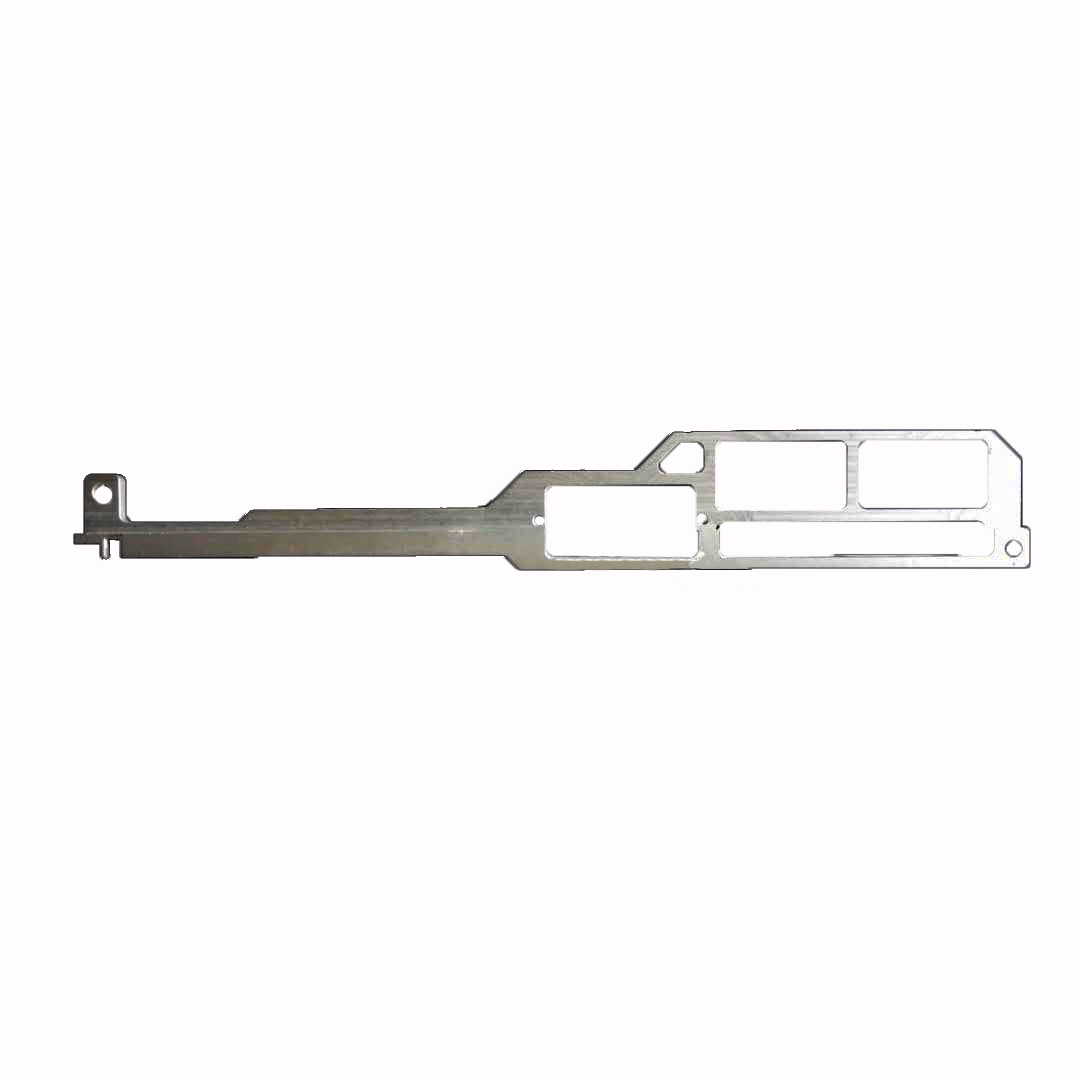

100% Original 2017 Hot Style Cnc Milling Machining Turning Parts Online

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable items at most aggressive selling prices. So Profi Tools give you ideal benefit of money and we have been ready to create with each other with 100% Original 2017 Hot Style Cnc Milling Machining Turning Parts Online, With a wide range, good quality, realistic charges and stylish designs,Our products and solutions are widely recognized and trusted by users and can fulfill continuously changing economic and social needs.

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable items at most aggressive selling prices. So Profi Tools give you ideal benefit of money and we have been ready to create with each other with Cnc Milling Maching Turning Parts, Hot Style, Online, Now, we professionally supplies customers with our main items And our business is not only the “buy” and “sell”, but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

CNC machining uses the world’s leading system, reliable operation, low failure rate, suitable for customer choice. Our company is located in a national civilized city with convenient transportation and unique geographical and economic conditions. We pursue a people-oriented, meticulously crafted, brainstorming, and create brilliant business philosophy. Strict quality management, perfect service, reasonable price in Argentina is the premise of our competition.

Features of digital control technology: Since the numerical control machine tool adopts the servo motor, the digital technology realizes the direct control of the working sequence and motion displacement of the machine tool. The gearbox structure of the traditional machine tool is cancelled or partially canceled, so the mechanical structure is greatly simplified. It is. Digital control also requires mechanical systems with high transmission stiffness and no drive clearance to ensure control command execution and control quality. Simultaneously. Due to the continuous improvement of computer level and control capability, it has become possible to allow more functional components to perform various auxiliary functions at the same time on the same machine. Therefore, the mechanical structure of CNC machine tools has higher integration functions than traditional machine tools.